Table of Contents

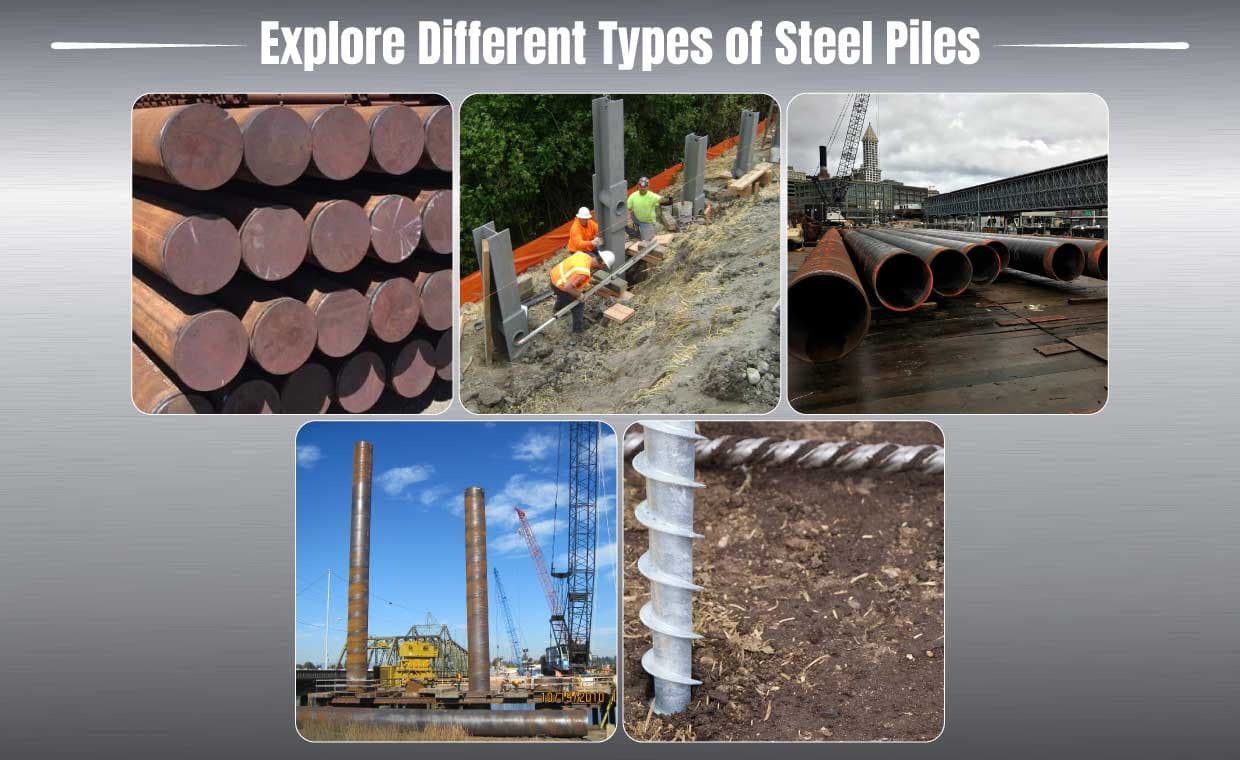

Steel piles have become an essential tool in the construction industry to provide stability and structural integrity for a wide range of projects. These structural components are driven into the ground to support buildings, bridges, and other structures. Steel piles are a popular choice in many construction projects due to their versatility, durability, and load-bearing capacity.

Gharpedia offers detailed insight into types of steel piles, including their advantages, disadvantages, durability, susceptibility to corrosion, and methods of preventing corrosion on steel piles.

What are Steel Piles?

Courtesy - Flickr

Steel piles are precast structural elements made of steel, driven into the ground to carry loads. They can come as rolled sections, fabricated shapes, or sheet piles. Two or more sheet pile sections can also be connected in a box shape and driven into the ground as a single pile. The primary benefit of adopting a steel pile foundation is its load-carrying capacity, which can reach up to 100 tonnes per pile.

Steel piles are widely used as foundations for massive structures such as port harbours, bridge construction, retaining walls, cofferdams, and pile foundations in areas with soft or dense soil. Since the firm strata are only available at higher depths, steel piles are driven into the ground to improve load-carrying capacity in soft soil conditions.

Characteristics of Steel Piles

- Steel piles have a small sectional area, resulting in minimal soil displacement and reduced vibration during installation.

- Steel piles can be manufactured in various lengths, diameters, and thicknesses to suit specific project requirements.

- Reinforcing bars in the upper portion of the steel pile make it simple to connect them to the superstructure.

- Steel piles are durable and lightweight, making them easy to handle and transport.

- When driven into the ground, steel piles offer high load-bearing capacity.

- They are resistant to horizontal stresses imposed by earthquakes due to their stiffness and bending strength.

Types of Steel Piles

There are four different types of steel piles, which are:

1. H – Piles

Courtesy - Flickr

With modern technology in the piling industry, steel piles, particularly H-piles, perform exceptionally well as bearing piles. H-piles endure the high-impact forces that occur during intense driving. This type of steel pile is extremely useful when the pile needs to penetrate rock or other hard substratum. To protect thinner sections, both the flanges and the web are rolled to the same thickness. To ensure rigidity in the weak axis, the flange width is made to be at least 85% of the depth of the pile section. Rolled steel H-piles have a smaller cross-sectional area. This makes it easier to move soil without having to use additional methods like water jetting, coring, etc. These piles are most commonly used in places with rocky or hard strata.

Advantages of H – Piles

Here are some major advantages of H piles:

- When compared to other steel piles, the requirement for storage space is quite low.

- The handling of H-piles is simple.

- This kind of steel pile can work both as a friction pile and a compaction pile.

- The process of splicing is simple.

- Driving H-piles causes very little soil movement.

- H piles can be driven to a depth of up to 100m.

- It is possible to drive H piles closer to the existing structure.

- H-piles are frequently employed in the construction of retaining walls, cofferdams, bridges, and other structures.

2. Pipe Piles

Courtesy - Flickr

Pipe piles are made from welded or seamless pipes, often filled with concrete. These piles are driven into the ground, either capped or uncapped, and then filled with a hardening material, such as concrete after the driving process is complete. These steel pipe piles can function as either end-bearing or friction piles, depending on the design and application. It is important to consider the soil conditions on the site while deciding between open-end and closed-end types.

I. Closed End Piles / Capped

Courtesy - JD Steel

The driving end of pipe piles is either capped or welded. Typically, a steel or cast iron conical/cap is welded to the driving end.

After driving the pile into the soil, the necessary amount of concrete is poured into it. In most cases, the diameter of the pile can range anywhere from 0.25mm to 1.2mm, while the thickness of the pile can be anywhere from 8mm to 12mm. One can use closed-end piles in situations where cleaning the interior of the piles is challenging.

II. Open End Piles / Uncapped

Courtesy - Eiffel Trading

The open-end piles can be driven to the necessary depth, and the soil within the pipe is removed with water jetting and a compressed air process; the hollow pipe is then filled with concrete. When driving an open-ended pipe, the soil inside the pipe can be cleaned as the driving advances, allowing for greater depths to be reached. If rocks or other obstructions are encountered before reaching the necessary depth, they can be removed using a cutting bit or, in the case of large diameter pipes, by blasting.

Advantages of Open End Piles:

Here are some advantages of open end piles:

- Pipe piles provide greater friction than other types of steel piles.

- The weight is evenly distributed due to the cylindrical shape.

- To withstand structural loads, these hollow pipe piles can be filled with concrete and strengthened with rebars.

3. Screw Piles

Courtesy - AAU Innovation

Screw piles are made of cast iron or steel. These piles form a long shaft with a helical or screw-shaped base. The exterior diameter of the shaft ranges from 15 cm to 30 cm, while the diameter of the screw base ranges from 45cm to 150 cm.

The shaft of a screw pile might be hollow or solid. An electric motor is used to drive the pile into the ground. It is suitable for loose sand and clay.

In such terrain, installing piles is simple, and the low bearing capacity of the soil is fully utilised by the large bearing area offered by the screws.

Advantages of Screw Piles

Here are some of the advantages of steel screw piles:

- Screw pile installation is simple, requires fewer machines, and less time.

- The use of screw piles helps reduce the carbon footprint.

- There is no need to remove soil from the site while driving screw piles.

- It is possible to install screw piles near existing structures.

- It is simple to remove screw piles when they are no longer required.

4. Disc Steel Piles

The arrangement of disc steel piles is similar to that of screw piles, except that disc steel piles are made of solid cast iron and have a cast-iron disc attached to the base of the pile. This disc enhances the pile’s bearing area. Like screw piles, these are suitable for use in soft or sandy soil. A hole at the bottom of the pile facilitates the water jetting process during penetration into the ground. It is primarily used in marine construction, where a deep pile penetration is necessary.

Advantages of Steel Piles

Here are some advantages of steel piles:

- Steel piles can penetrate rocky and hard strata.

- They increase the structure’s strength and durability.

- Soil displacement is minimal during steel pile penetration.

- These piles can withstand rigorous handling.

- Steel piles have a higher bearing capacity than others.

Disadvantages of Steel Piles

Here are some disadvantages of steel piles:

- Prone to corrosion and electrolysis damage.

- They are relatively expensive, except when the bearing stratum may develop a substantial pile capacity.

- Steel piles are not as efficient as friction piles.

Corrosion Of Steel Piles

Corrosion can impact embedded steel piles, especially when the surrounding layer consists of materials such as cinder fills, coal, alkaline soils, plant waste, etc. A major issue with steel piles is their susceptibility to corrosion. Some methods for preventing corrosion on steel piles include:

1. Additional Thickness

Most codes follow this technique, which specifies that the pile section should be thicker than the minimum sectional area required for strength. Typically, this extra thickness is 1/16 inch. To do this, either subtract 1/16 inch from the actual metal thickness when calculating the pile’s capacity or splice an additional piece of steel to the pile length where corrosive action is expected.

2. Removing Corrosive Soils

Near the ground surface, organic soils, cinder fill, unburned carbon, or industrial waste may be removed and replaced with noncorrosive soils. It is only cost-effective if these soils are located at relatively shallow depths.

3. Concrete Encasement

When the piles are close to the surface, where there is plenty of water and air, they can be covered with a concrete casing. However, using concrete encasement that extends deeply is an expensive option.

4. Cathodic Protection

Corrosion results from a steady loss of electrons from the piles; hence, any method that prevents this loss would be effective. One such method is the cathodic technique, in which a slow current is directed toward the steel piles instead of away from them.

It’s worth noting that painting or other coatings applied before driving are probably useless because the coating in the embedded area is so vulnerable to degradation from abrasion and handling that it’s not worth the effort. Periodically, piles that extend into the air should be repainted. Concrete casing or coal tar paint can safeguard pilings that extend into contaminated water. In freshwater, the section near the water’s surface must be protected.

Durability of Steel Pile

When the rate of corrosion is low, no protective method is required; however, when the rate of corrosion is significant, a protective method is used for piles.

The methods used are as follows:

- Coat the piles with a protective layer

- Make use of a thicker section

- To avoid corrosion, use high-quality steel

- The use of cathodic protection for piles

- In marine area use of ASTM960 (SPLASH ZONE)

- Extra concrete capping

Conclusion

In construction projects all throughout the world, steel piles are essential structural components that are strong and economical. From retaining walls and foundation systems to offshore platforms and maritime constructions, steel piles provide unparalleled stability and load-bearing capacity in a variety of applications. By understanding the different types of steel piles and their benefits, engineers and contractors can choose the most appropriate option for their projects.

FAQs on Types of Steel Piles

1. How many types of steel piles are there?

There are four major types of steel piles, namely,

- H-piles

- Pipe Piles

- Screw Piles

- Disc Piles

2. How to prevent corrosion in steel piles?

There are certain methods to prevent steel piles which are:

- Removing corrosive soils

- Concrete encasement

- Cathodic Protection

Also Read: Type of Pile Foundation: Select Appropriate for Your House, if Needed!

Author Bio

Fathima Israr Khan – I’m Fathima Israr Khan, an MTech second-year student in Geotechnical Engineering at NIT Silchar.