A flush door is a simple interior or exterior door that has plain facings on both sides of the construction. It is commonly used in the residential and public buildings. A flush door is most commonly used in the house because of its pleasing appearance, durability, and easy availability in the market.

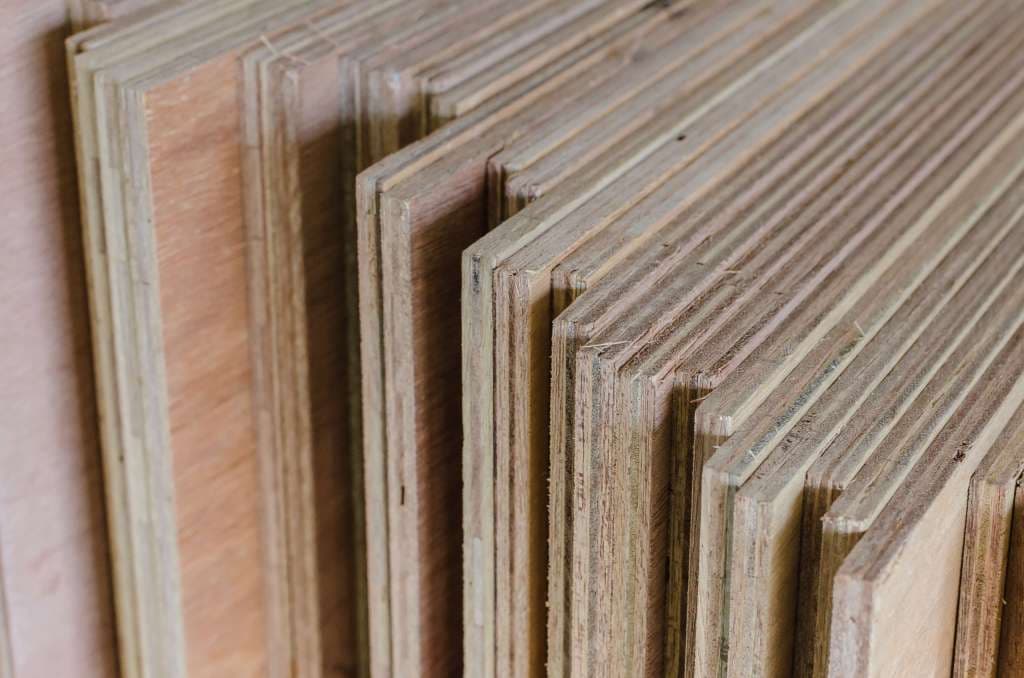

Different types of plywood are used in making of doors, but there are certain plywood grades which are most commonly used in the making of the flush door which are given below. The selection would depend on the strength and its resistance to water and moisture.

01. BWP Grade Plywood or Boiling Water Proof Plywood

- BWP grade plywood is made of a single select hardwood species and bonded with boiling water proof synthetic undiluted phenol formaldehyde adhesive. Its hardwood frames provide strength for the fitting of hinges.

- It is chemically treated to protect against shrinkage, warping and cracks.

- The thickness of the BWP grade plywood may be 6mm, 9mm, 12mm, 16mm, 25mm, etc. as per IS.

- BWP flush door is extremely durable and has a good quality, exceptional finish and unique dimensional stability. These doors provide assured strength and safety.

- It requires minimum maintenance. It has a better water resistance.

- It is basically interior and exterior grade plywood. Therefore it is likely used where the furniture that sure get large amount of water i.e. bathroom door, outdoor wall paneling, flooring, etc.

- BWP grade plywood more expensive than BWR grade plywood.

02. BWR Grade Plywood or Boiling Water Resistant Plywood

- BWR grade plywood is glued using synthetic phenolic resins giving it its unique water-resistant property. Superior diluted phenol formaldehyde (PF) resin is used for super bonding and hardwood species are used for long life.

- BWR grade plywood is comparatively less strong as compared to BWP grade plywood.

- It can resist warping even when exposed to water for long periods.

- The thickness of BWR Plywood may be 3mm, 4mm, 6mm, 9mm, 12mm, 16mm, 19mm, 25mm, etc. as per IS.

- BWR grade plywood is weather-proof. It is not 100% waterproof as compared to BWP grade plywood.

- It is basically exterior grade plywood therefore itis also ideal for making furniture that likely to get wet. i.e. kitchen cabinets, lawn chairs, garden tables and chairs or those used in restaurants and cafes, false ceiling, etc.

03. MR Grade Plywood or Moisture Resistant Plywood

- In this type of plywood, urea formaldehyde resin is used for bonding the plies to each other.

- MR grade plywood can resist a certain degree of moisture and humidity only.

- This grade is moisture resistant; it is not resistant to water. So this type of plywood is not used to make furniture perennially exposed to water.

- The plywood is capable of resisting humidity and moisture.

- The thickness of the MR grade plywood may be 3mm, 4mm, 6mm, 8mm, 12mm, 15mm, 18mm, 21mm, 25mm, etc. as per IS.

- MR plywood has a very high internal strength.

- Its cost is low.

- It is interior grade plywood; therefore it is suitable for indoor use and not for exterior.

- It is used mainly in the interiors of a home or office.

- It is also suitable for making furniture like kitchen shelves, partition, wall mounted cabinets, wardrobes, TV tables, showcases, racks, etc.

Therefore choosing the right plywood grades in making of flush door improves durability and aesthetic of your house. BWP grade is superior grade of plywood than BWR and MR grade plywood. Phenol formaldehyde resin adhesive is stronger than urea formaldehyde resin. Therefore BWP and BWR grade plywood is more suitable for furniture than MR grade plywood. In short, BWP is better than BWR and BWR is better than MR grade plywood.