All house hold appliances do not require the same water flow. For example: Bathtubs requires more flow of water so that they can be filled early as well as water gets mixed vigorously with air and shower gel forming foam. Basin requires less flow of water because of its usage and capacity.

High water flow rate causes wastage of water and low water flow causes inconvenience to the users. To use water judiciously it is necessary to regulate the flow of water. Flow of water can be regulated installing valves.

Valve is a device or switch that can turn pipes on and off or raise or lower the amount of water flowing through them. It blocks a pipe either partially or completely to change the amount of water that passes through it. For example: when watering a garden we keep a thumb on pipe, this act as valve as it delivers a controlled flow of water with jet effect to reach distant areas. Basically all valves have an inlet, an orifice or a disc, which close the orifice and an outlet. Both inlet and outlet are called parts.

Valves have 3 Functions:

01. Start/Stop Valve:

It only starts or stops the flow of water without controlling/guiding/directing the water flow to any particular direction.

02. Throttle or Control Valve:

These valves controls the speed and capacity of flow through the supply/distribution system.

03. Non-Return Valve:

Also known as check valve. These valves checks on the direction of flow. It allows the flow of water through them only in one direction. Mainly, used for preventing backflow to the system.

Following are the different types of valves generally used:

01. Sluice Valve or Gate Valve:

Sluice valves are used for controlling the flow or completely stopping the flow in a pipeline. It is used at connection of main line and branch line to start/stop the water flow into house. Sluice valve or gate valve is commonly known as stop cock/stop valve.

02. Scour Valve or Blow-off Valve:

Scour Valve is also called as Blow –off Valve. These are the ordinary valves used for a specific purpose of scouring or emptying or cleaning the mains and emptying water tank. It removes sediment and allows the line to be drained for maintenance and repair work. These are located at the bottom of water storage tank, and opened to empty the tank for cleaning purpose.

03. Bypass Valve:

The objective of a bypass valve is to relive the unbalanced pressure on a sluice valve gate and thus reduce the operating forces.

04. Float Valve or Ball Valve:

For automatic regulating the flow, the float valve or ball valve is used. Regulating principle is the level of free water surface. A float valve or ball valve may be arranged to allow water to flow until a predetermined level is reached when the valve will shut and will open again as soon as the level drops or rises. These are usually placed in water storage tank.

05. Reflux Valve:

Reflux Valve is also called as NRV (Non-Return Valve) and Check valve. This is a valve where flow can proceed in one direction only. Reflux valves are generally used on gravity and rising mains as they permit water to flow in one direction only and check all the return flow.

06. Flap Valve:

Flap Valve is one type of reflux valve. A single door or flap hinged so that when hanging freely the valve is closed. Flow in the forward direction causes the door to swing open, the amount of opening depending upon the velocity of flow and weight and disposition of the metal of the door.

Courtesy – engineerlive

07. Pressure Relief Valve:

A pressure relief valve is used for the purpose of maintaining head on pumping mains when delivering to high-level areas.

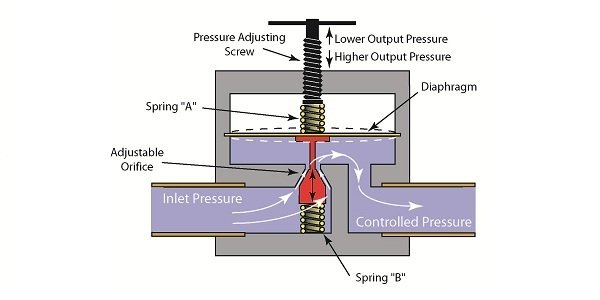

08. Pressure Reducing Valve (PRV):

Pressure Reducing Valve is used to automatically maintain a reduced pressure within reasonable limits on the downstream side of the pipeline. Particularly in a high rise building, these are mostly used in domestic water supply systems as the water flowing at high pressure may damage other domestic water supply systems and other equipment connected to the line.

Also Read:

Direct Water Supply System

Indirect Water Supply System

Courtesy – CTG India

09. Pressure Sustaining Valve:

These are similar to the pressure reducing valves and are used to maintain automatically the pressure on the upstream side of the pipeline.

10. Air Valve:

These are fitted to release the air automatically when a pipeline is being filled and also to permit air to enter the pipeline when it is being emptied.