Concrete contains ingredients such as cement, sand, Coarse aggregate and water in properly designed proportions. This proportion is arrived at either as a nominal mix or by design mix. All the materials have their specific properties and importance to contribute to the strength of concrete. Cement is used as a binding material in concrete due to the best Adhesive and Cohesive property while water is the cheapest and most important ingredient of concrete. When these two materials are mixed, a chemical reaction takes place named hydration. Hydration reaction produces a sticky and thick gel which has a binding property and which bind all aggregate in form of tough and strong material. Thus cement and water both are responsible for binding all elements of concrete together.

Fresh Concrete

Image Courtesy – Bhanuconcrete

Cement and water are used as per their ratio called Water-Cement Ratio. Water-Cement Ratio is defined as the ratio of the weight of water to the weight of cement. Water/cement ratio as per IS 10262 (2009) for the concrete mix varies from 0.4 to 0.6. 0.7 w/c ratio is also used for pumped concrete. 0.5 w/c ratio indicates, that for every 100 kg of cement, 50 lit. of water is added. With an increase of w/c ratio amount of water is increased.

Why Do We Need to add Sufficient Water to the Concrete Mix?

Technically as per studies, cement requires 23% of water for the hydration process and 15% for expansion of pores and volume increment. Therefore 38% of the water by weight of cement is minimum and must.

From experimental data, it has been found that for full hydration of cement paste and no capillary pores to be left there, sufficient water is required in the concrete mix. The least quantity of this water corresponds to 0.38 w/c ratio. Thus, if water-cement ratio is less than 0.38, complete hydration is not possible. If it is more than this concrete mass become porous and permeable and if it is less concrete becomes dry and harsh and may not bind and develop full strength.

For workability consideration, this water-cement ratio is found as 0.4, but its selection depends on the requirement of workability in different exposure conditions and nature of work. At a water-cement ratio of 0.4, the mix has sufficient water for hydration as well as for providing ease in the concreting process like mixing, placing, transporting and compacting. Because water works as a lubricant in the concrete mix and reduces the internal friction between particles of concrete.

At this water-cement ratio, the ‘gel’ formed is in good physical structure and dense. At higher water/cement ratio the ‘gel’ formed is in the poor physical structure, create voids during subsequent evaporation and become more porous, resulting in a lower strength of concrete at a later age.

Simple Calculation of Water Quantity for Concrete

If we need to calculate the quantity of water for concrete mix, first find the cement content for the volume and w/c ratio.

If we assume 80 kg of cement for concrete mix and w/c ratio is 0.45

Required amount of water = Cement volume X w/c ratio

Therefore, required water quantity is 80 kg X 0.45= 36 lit.

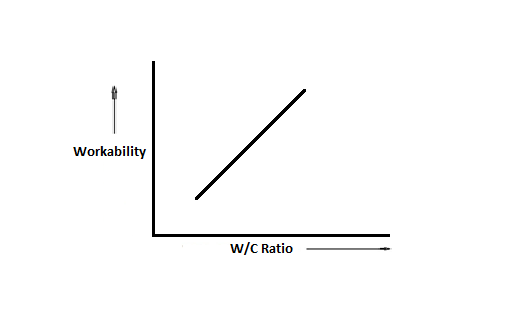

Effect of Water-Cement Ratio on Workability

Workability of concrete means the ability of concrete to perform concreting process like mixing, transporting, placing, compacting with ease and without any segregation. In other words, workability of concrete indicates the ability of concrete to work easily. W/C ratio is also an important consideration for the workability of concrete. High w/c ratio leads to higher workability because inter particle lubrication is increased. Similarly, lower w/c ratio leads to lower workability because there is lack of interparticle lubrication. Graph of Workability vs. w/c ratio is shown below. This may lead to porous concrete.

W/C ratio varies from 0.4 to 0.6 depending on the exposure condition as per IS 10262 (2009). A ratio of less than 0.4 makes concrete very stiff (if superplasticizers are not used) and a ratio of greater than 0.6 makes a wet and weak concrete and perhaps leaking concrete leading to corrosion in future.

Using low w/c ratio is the usual way to achieve high strength and high-quality concrete, but w/c ratio alone does not generate the strength of concrete. Good concrete results from a good mix design and a low w/c ratio is one but very empirical part of a good mix design.

Higher the water-cement ratio means the higher quantity of water which results in dilution in cement paste. It makes poor concrete mix and increases water permeability. Thus, leads to leakage and dampness. It makes concrete weaker and more susceptible to cracking and shrinkage. Shrinkage produces micro cracks, and it is a zone of weakness.

Also Read:

How to Avoid Cracks in Concrete?

Plastic Shrinkage Cracks: All you Wanted to Know

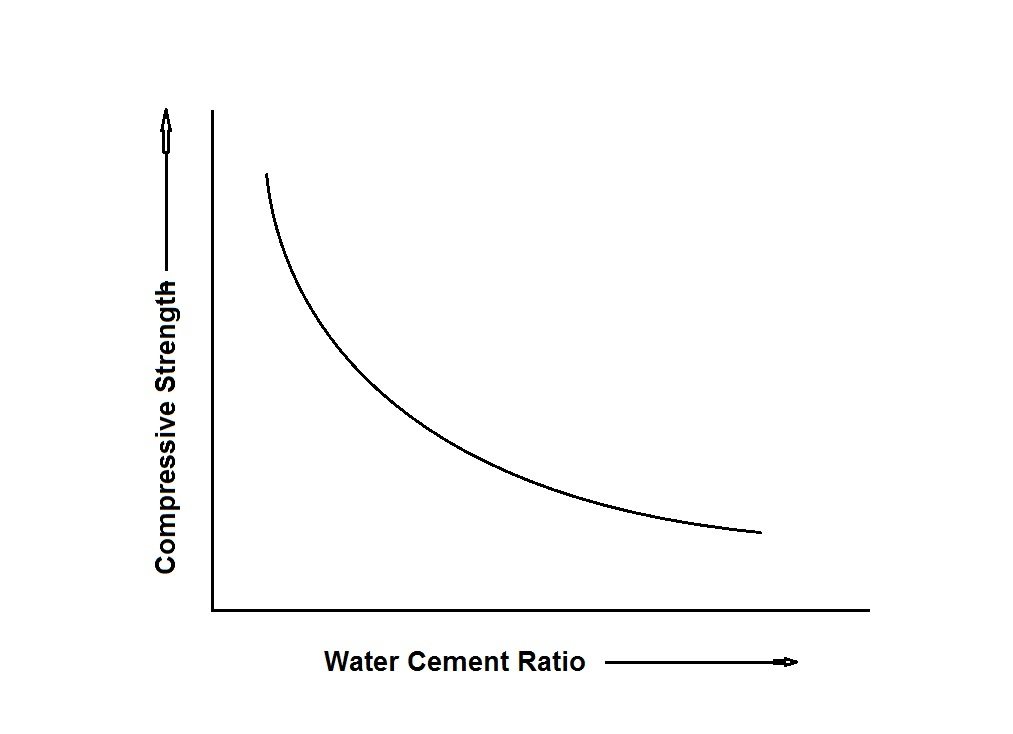

Example, having 0.4 water-cement ratio gives 5600 psi (pound-force per square inches) or 394 kg/cm2 (Kilogram-force per square centimeter) compressive strength whereas 0.7 water/cement ratio reduces compressive strength up to 1067 psi or 75 kg/cm2 or even less provided allow other factors are constant.

The low w/c ratio increases strength meanwhile it decreases workability and makes concrete non-workable. This is the biggest problem while designing a concrete mix with low w/c ratio. For overcoming this problem; we can use admixtures like Water reducing admixtures (WRA), superplasticizers (High Range Water reducer) etc. These admixtures are added to the concrete to achieve certain workability at low w/c ratio and make high strength and dense concrete. Nowadays plasticizers and superplasticizers admixtures are widely used in construction industry.

Effect of Water-Cement Ratio on Strength

The compressive strength of concrete is a major characteristic of the concrete mix. Change in the amount of water changes the strength of concrete. If water is used in more quantity, it may develop more voids and develop honey-combed structure to a large extent in set concrete. It results in decrease in density, durability and strength. Lower the water/cement ratio, the greater the strength of concrete.

Duff Abrams’ Law for Water-Cement Ratio

American Researcher Duff Abrams’ gave a concept on water/cement ratio which known is as “Abrams’ water/cement ratio law”. As per Duff Abrams’ law strength of concrete is inversely related to the W/C ratio. If w/c ratio increases, the strength of concrete decreases. Compaction of concrete is also important because, If concrete is not properly compacted it contains large voids, which leads to porosity. Thus, at a low water/cement ratio, where fully compacting is hard to achieve, Abrams’ law is not valid.

Decrease in compressive strength with an increase in water/cement ratio illustrated graphically below,

Water-cement ratio is the most important factor which affects the properties of concrete. Selection of water-cement ratio depends on various factors like requirements of strength, workability, concreting techniques, nature of work etc. General criteria why the low water-cement ratio is recommended are as below.

Following reasons why high water-cement ratio is not recommended:

- Chances of segregation and bleeding

- Less durability

- Development of voids

- Decrease in strength of concrete

- Decrease in life of structure

- Leakage and chances of corrosion

- Increased carbonation due to voids and hence reduce life

- Freeze-thaw effect etc.

Following major reasons why the low water-cement ratio is recommended:

- Increase in strength

- Increase in durability

- Lower permeability

- No leakage or dampness

- Greater freeze-thaw durability

- Better bond with reinforcement etc.

Must Read:

Causes of Leakage in Buildings

Corrosion in concrete