The joints are provided in building construction for continuity of structural action between the members meeting at the joint. In building construction terminologies, the word beam column joint is used to cover elements that have to perform a completely different function. Let us understand everything about the concrete beam column joint.

What is a Beam Column Joint?

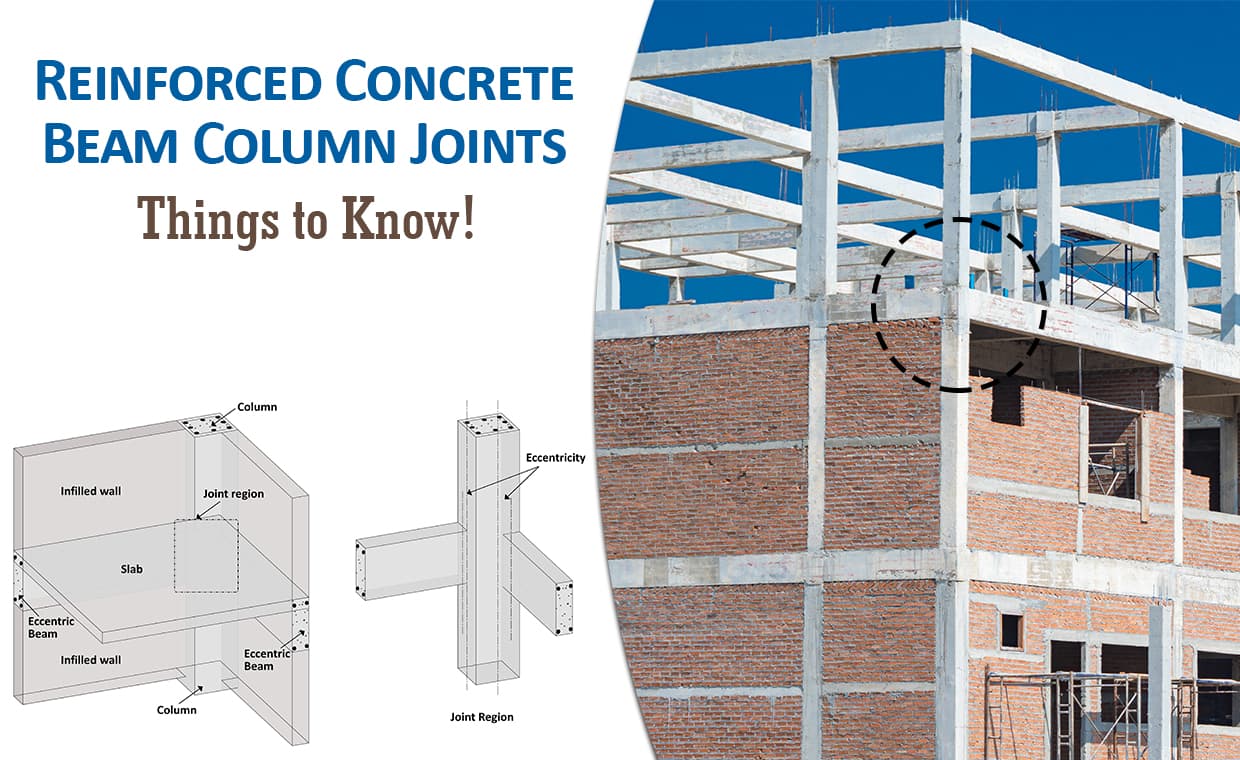

The portion of the column that is common to beam at their intersection in a building is known as the beam column joint. In other words, according to American Concrete Institute – ACI 352R-02[387], beam column joint is defined as the portion of the column within the depth of the deepest beam that frames into the column.

The beam joints with the columns are the most critical area in the design of a reinforced concrete building. The primary purpose of the provision of a beam column joint in reinforced concrete building is to transfer the load from connecting members effectively while experiencing both gravity loads and during seismic excitation.

The beam column joint is an essential component of a reinforced concrete moment resisting frame. It should be designed and detailed correctly, especially when the structure is subjected to earthquake loading. Failure of a reinforced concrete beam column joints during earthquakes is governed by the bond and shear failure mechanism, which is brittle.

After understanding the basics of the beam column joint, let’s have a look at the types of beam column joint in Reinforced concrete Building.

Types of Beam Column Joints in Reinforced Concrete Structure

1) Classification According to Connection Geometry (Indian Standard Classification)

a. Interior Joints

The joint is called an interior joint when four beams frame into the vertical faces of a column.

b. Exterior Joints

The joint is called an exterior joint, when one beam frame into the vertical face of a column and two more beams frame into the column in the perpendicular direction.

c. Corner Joints

The joint is known as corner joint, when the beams frame into two adjacent vertical faces of a column.

2) Classification According to Loading Condition (International Classification)

ACI-ASCE Committee 352[387] classifies the beam column joint in the following two categories:

a. Type 1 Joints – Non-Seismic Joints

Non-Seismic Joints are designed based on strength without considering special ductility requirements. Any joint in a structural frame designed to resist gravity load and normal wind loads (Horizontal loads) falls into this type of joint.

b. Type 2 Joints – Seismic Joints

Seismic Joints are designed to have sustained strength under deformation reversals into inelastic range. Joints in framed structures designed to resist lateral loads due to earthquake fall into this type of joint.

3) Classification According to Rigidity of Joint

These types of beam column joints are common in Reinforced concrete buildings and steel buildings.

a. Rigid Joint

The rigid joint deforms such that the members meeting at the joint at a right angle remain at the right angle after deformation. Thus, moments are transferred from beams to columns.

Beam column joints in a rigid-jointed frame structure are critical locations requiring careful design and detailing. Rigid beam column joints occur in multi-story frame building, at the base of cantilever retaining walls, box culverts, portal frames etc.

b. Pin joint

The pins in columns at a joint do not transfer moment from beams to columns due to pins. The pins at the column ends indicate moments are not transferred from beams to columns. If the bracing in some form is not provided, the structure becomes unstable.

c. Semi Rigid Joint

According to ‘JANAK P. PARIKH’[388] (Author of Book: UNDERSTANDING CONCEPT OF STRUCTURAL ANALYSIS AND DESIGN), all joints are essentially semi-rigid joints. However, it can be seen that the beam column connection of the steel beam in figure – (a) and RCC beam in figure – (b) are closer to simple supports offering little moment reaction, and the beam is called a simple beam.

Whereas the beam column connection of the steel beam in figure – (d) and RCC beam in figure – (e) are closer to fixed supports offering moment reaction, and the beam is called a fixed beam.

The reinforced concrete beam column joint is a monolithic structure and offers fixity. However, the reinforcement arrangement in the beam in above figure – (b) is such that there is not enough anchorage into the column. Therefore, the reinforcement cannot develop the required tension under the moment, and the crack develops as shown in the above figure – (g). In this case, the stresses are released, i.e. pins are developed which offer no moment reactions, and the beam behaves as a simple RCC beam.

The beam in above figure – (e) behaves as a fixed RCC beam because of enough top reinforcing steel and proper anchorage into the column.

The column reinforcement in the above figure – (a) can transfer only axial force and shear force through the column to the footing. The joint is so detailed that it cannot transfer at any moment. Under any moment, it develops a crack as shown in figure – (b). This is a classical pin joint column.

The section in figure – (c) is designed to transmit axial force through the column to the footing. The joint is not designed to transfer at any moment. However, because of its detailing [which is not classical pin as in figure – (a)], it may resist some moment. In this case, the reinforcement is just enough to take only axial force. Under a moment of action, a crack develops and stresses are released, and now a Pin develops. This joint effect is a semi rigid joint, which is closer to the pin joint.

The reinforcement in figure – (d) is designed and detailed such that it can transfer axial force, shear force and moment through the column to the footing. This joint effect is also a semi rigid joint, which is closer to a fixed joint.

After knowing the different types of beam column joints in the construction of reinforced concrete building, let us know all the necessary details of beam column joints, including analysis and design.

How to Create Reinforced Concrete Beam Column Joints?

The creation of any structure typically is carried out in alternating steps of analysis and design. Each step passes new information that permits the structural designer to proceed to the next phase. The process continues until the analysis indicates that no changes in member sizes are required. The specific steps of the procedure are described below:

Relationship of Analysis to Design

- The designer begins by considering all possible layouts and structural systems that might satisfy the requirements of the project.

- The engineer selects several the structural systems from conceptual design, that appear most promising, and then sizes their main components. This preliminary proportioning of structural members requires an understanding of structural behavior and knowledge of the loading conditions (dead load, live load, wind load etc.) that will most likely affect the design.

- At this point, the experienced designer may make a few rough computations to estimate the proportions of each structure at its critical sections.

- In the next stage, the precise loads that the structure will carry are not known because the exact size of members and may be architectural details of the design are not finalized. Using estimated load value, the engineer carries out an analysis of the structural systems under consideration to determine the forces at critical sections and the deflections at any point that influence the serviceability of the structure.

- The true weight of the members cannot be calculated until the structure is sized exactly, and certain architectural details will be influenced, in turn, by the structure. However, from previous experience of similar structures, the designer knows how to estimate load values relatively close to the final values.

- Using the results of the analysis of preliminary designs, the designer recomputes the proportions of the main elements of the structure. Although each analysis is based on the estimated load values, the forces established at this stage are probably indicative of what a specific structure must carry so that proportions are unlikely to change significantly even after the final design details are confirmed.

- The various preliminary designs are next compared with regard to cost, availability of materials, appearance, functionality, maintenance, time for construction, and other pertinent considerations. In the final design phase, that structure is so chosen that it satisfies the client’s as well as code’s acceptance criteria.

- In the final phase, the engineer makes minor adjustments in the selected structure that will improve its economy or appearance. Next, the designer carefully estimates the value of dead loads and considers specific live load positions that will maximize stress in particular sections.

- As part of the final analysis, the strength and stiffness of the structure are evaluated for all significant loads and combinations of load i.e. dead load, live load, including wind load, snow load, earthquake load etc.

- If the results of the final design confirm that the proportions of the structure are adequate to carry the design forces, the design is complete.

- On the other hand, suppose the final design reveals certain deficiencies for example, certain members are overstressed, the structure cannot resist lateral or wind loads efficiently, members are excessively flexible, over the budget cost of design etc. In that case, the designer will either have to revise the configuration of structure or take an alternative structural system.

According to ‘Kenneth M. Leet et al’[389] (Author of a book – Fundamentals of Structural Analysis), reinforced concrete structure, steel structure and wooden structure are all analyzed in the same manner. The different properties of materials are taken into account during the design process. When the size of all the members is determined, the designers refer to the design code for the special properties of each material.

Beam-Column Joint Design In Reinforced Concrete Building

A beam-column joint undergoes severe stiffness and strength degradation when subjected to earthquake loads. The essential requirements for the satisfactory performance of building during an earthquake can be summarized as follow:

Requirements of Beam Column Joints

- A joint should exhibit a service load performance equal to or higher than that of the members it joins. The failure should not occur within the joints.

- According to ‘N Subramanian’[390] (Author of a Book: Design of Reinforced Concrete Structures), A joint should possess strength not less than the maximum demand corresponding to the development of the structural plastic hinge mechanism of the structure. This requirement will eliminate the need to repair a structure in an inaccessible region.

- In moderate earthquakes, the joint should behave elastically.

- The deformation of joints should not significantly increase the story drift or should remain within permissible limits.

- The joint configuration should ensure good access for placing and compacting concrete and ease of fabrication in the joint region.

- If deformation under the action of lateral forces is to be reliably quantified and subsequently controlled, designers must make a realistic estimate of the relevant property called stiffness. It is related to loads or effects ensuring structural deformations.

- If the concrete structure is to be protected against damage during a seismic event, inelastic deformation must be prevented during its dynamic response. This means that the structure must have sufficient strength to resist the internal actions that occur during the dynamic response. Therefore, based on the stiffness properties, the appropriate technique should be used to evaluate seismic-induced effects.

- Beam column joint is designed to minimize significant damage and to ensure the survival of buildings with moderate resistance with respect to lateral forces. Also, structures must be capable of sustaining a high proportion of their initial strength when a significant earthquake imposes large deformations.

The joint block area is relative to the member sizes, so it is essential to consider localized stress distribution within the joints. A simplified force system can be adopted in designing beam-to-column joints.

The required steel quantity is calculated on the assumption that steel reaches the design yield stress and the concrete its designed compressive stress. Where local bearing or bond failure is expected, the lower of the two capacities should be adopted based on experimental results. It is essential to prevent anchorage and bond failure within the joints through proper beam-column joint detailing and design practices, especially at the external joints.

The Design Procedure of Beam-Column Joints in Reinforced Concrete Structure Consists of the Following Basic Steps:

- Start from the preliminary size of members based on anchorage requirements for the chosen longitudinal bars.

- To get the desired beam yielding mechanism, ensure sufficient flexural strength of columns.

- Arrive at the design shear force for the joint by evaluating the flexural over strength of the adjacent beams and corresponding internal forces in columns that maintain equilibrium.

- Obtain effective joint shear area from the adjoining member dimensions.

- Ensure that the induced shear stress is less than the allowable stress limit. The allowable shear stress limit is expressed as a function of diagonal tensile strength or the compressive strength of concrete. If not satisfied, alter the associated member dimensions.

- Provide transverse reinforcements both as shear reinforcement and as confining reinforcement.

In most cases, the reinforced concrete joint is a rigid joint because of the monolithic nature of the material. However, it is the reinforcement detailing or the way in which reinforcement is placed offers the member rigidity or flexibility. Hence, beam and column joints are rigid or flexible depends upon the detailing.

The detailing eventually changes the load transferring pattern of a member. For example, the slab in the above figure is supported on all four sides, and the ratio of long span to short span is greater than 2. So it is a one-way slab.

As detailed in above figure – (c), the slab reinforcement is a right detailing as main steel is spanning in the short span direction (span Lx). However, let us see what happens if the required designed main reinforcement is provided in the long span (span Ly) as shown in figure – (d).

The slab having the supports on all four sides transfers major load in the short span direction (span Lx). Therefore, the moment is developed in the short span direction. But they do not have proper reinforcement in the short span direction, as a result, the concrete cracks as shown in figure – (d).

Now the cracks release the stresses, and then the load is transferred in the long span direction (span Ly). So now, the designed reinforcement placed in the long span direction (span Ly) tries to resists the load.

- Provide sufficient anchorage length for the reinforcement passing through or terminating in the joint.

The design and detailing of reinforced concrete beam column joints are critical in assuring safety during earthquakes. Thus beam-column joints must be designed to resist effects due to earthquake.

However, the most severe earthquake can only be survived if the members are sufficiently ductile to absorb and dissipate seismic energy by inelastic deformations. For reinforced concrete members to have adequate strength and ductility to withstand earthquakes, their design and detailing must conform to Indian standard – IS 456: 2000[99] (Plain and Reinforced Concrete – Code of Practice) and Indian standard – IS 13920: 1993[391] (Ductile Detailing of Reinforced Concrete Structures Subjected to Seismic Forces– Code of Practice).

The detailing provisions in Indian standard – IS 13920: 1993 provide reinforced concrete members with adequate toughness and ductility and make them capable of undergoing extensive inelastic deformations stably dissipating seismic energy. According to ‘Shashikant K. Duggal’[392] (Author of a book called Earthquake-Resistant Design of Structures), the stiffness of RCC can be used to minimize seismic deformations and hence reduce damage to non-structural members.

In addition, if you want to know about the beam column joints in steel structure and wooden structure, refer the following link for beam column joints in steel structure –

Click the following link to view beam column joints in the wooden structure –

Types of Beam to Column Connections in Timber Structure Design

Effects Due to Improper Analysis and Design of Beam Column Joints

Beam column joints are special in buildings, these are portions of columns familiar to beams at their intersections and are made of constituent materials that have limited strengths; hence, the joints have limited force carrying capacity. The joints are severely damaged when forces larger than these are applied during earthquakes. Repairing damaged joints is complex, so damage must be avoided; beam column joints must be designed and detailed to resist earthquake effects.

During an earthquake loading, joints in structures are inferior to most other types of joints. The failure of joints connecting columns and girders frequently occurs, causing the building to collapse. Joint failure results in a change of angle between the columns and beams, and the building starts titling progressively till it collapses.

How to Achieve Beam Column Joints on Site?

- To achieve correct beam column joints on-site, the designer needs to give details in the drawing of the beam column joint.

- The beam-column joint detailing is shown on the drawing, and they must be made mandatory. It is best to study the place and detailing of such joints before starting work.

- It becomes the duty of site engineer to meticulously check the joint detail.

- All the joints need to be constructed with great care for preventing any collapse of the building.

Summing up, the performance of framed structures depends upon the individual structural elements as well as the integrity of joints. The detailing and design of beam column joint is an essential component in building design. This article presents you with types of concrete beam column joints, design requirements, Analysis to Design relationship and design procedure. Well-designed joints will provide the desired service performance and improve the appearance of a structure.

A variety of factors affect the life of a house, but joints in construction play an important role in the building’s longevity. If you want to learn about the different types of joints used in concrete slabs and walls, click on the following link –

Joints in Construction: All You Need to Know