Fibre is a long slender thread or filament from which some material is formed. Carbon fibre is a discrete reinforcing material produced from carbon. Also, they can be manufactured as a mat or continuous straight fibre.

Concrete is a composite material and widely used all over the world. Concrete is used as a construction material, but it has its own limitations i.e. brittleness, low tensile strength and poor crack resistant. Thus, to overcome these weaknesses, Steel is provided in concrete to improve its limitation, which is called Reinforced Cement Concrete. Use of steel reinforcement in concrete increases the strength and ductility. Carbon fibre is gradually emerging as a popular alternative to steel and aluminum due to its commanding strength, stiffness and moreover, it is comparatively lighter in weight than its competitors.

Alternatively, Introduction of fibres in discrete form in plain or reinforced concrete also provides a better solution. The concept of using fibres to improve the characteristics of construction materials is ancient. When concrete cracks, the randomly oriented fibres start functioning, arrest cracks and their propagation, thus, improving strength and ductility.

The Different Types of Fibres which are used as Reinforcing Materials are:

01. Carbon Fibres

02. Glass Fibres

03. Steel Fibres

04. Synthetic Fibres

05. Natural Fibres

Here, in this article, we have focused on key factors that are driving the utilization of Carbon fibre and its potential applications in construction industry.

History of Carbon Fibre

The 20th century saw a roller coaster ride in the demand for carbon fibres. Carbon fibres have revolutionized the technology of materials. But the history of it goes long back. According to ‘Daniel B. Miracle & Steven L. Donaldson’ (Author of ASM Handbook Volume 21 Composites), The earliest commercial use of carbon fibres is often attributed to Thomas Edison’s carbonization of cotton and bamboo fibres for incandescent lamp filament. However, commercial use of carbon fibres for reinforcement applications began in the late 1950s with the pursuit of improved ablative materials for rockets.

Dupont’s work with “black Orlon” in the late 1950s showed that acrylics could be thermally stabilized, while Shindo in Japan and Watt et al. in the United Kingdom demonstrated that by using tension through the carbonization process, high mechanical properties could be realized.During the 1960s and 1970s, research on carbon fibres rapidly increased to improve the performance/price ratio. Much of this effort was focused on the evolution of various precursors. “Donnet and Bansal present a good overview of various researchers’ efforts to evaluate different precursors including PAN (Polyacrylonitrile), pitch, rayon, phenol, lignin, vinyl polymers and various naturally occurring cellulosic materials.”

Overall, carbon fibre demand grew to approximately 1000 metric tons by 1980. By the mid-1990s, a new cost-effective, PAN-based carbon fibre made from a modified textile precursor was being aggressively promoted by various companies (i.e. Zoltek and Fortafil) for commercial applications.

Continuous research and investigation made the usage of carbon fibre in 1997 were estimated at 30% in aerospace, 30% in sports equipment and 30% in commercial or industrial applications with the industrial applications poised for the most significant growth.

What is Carbon Fibre?

Carbon fibre is a solid, lightweight material. It is five times as strong as steel, two times as stiff, yet weighs about two-third less and has a much higher load bearing capacity. Carbon fibre is made up of carbon strands that are thinner than a human hair. The strands can be woven together, like cloth, and can be molded in any shape you might want.

Carbon fibre also known as Graphite fibre, is composed of long strands of fibres that are interwoven together to form a fabric like structure. Carbon fibre is defined as a fibre containing at least 92 wt % carbon, while the fibre containing at least 99 wt % carbon is usually called a graphite fibre.

In addition to being strong, carbon fibre is also flexible. Hence it is a perfect material for construction projects in areas which are exposed to hurricanes and tornados. i.e. subjected to high impact loads. The majority of today’s carbon fibre is produced with rayon, PAN (Polyacrylonitrile) or Pitch (a product of petroleum refining).

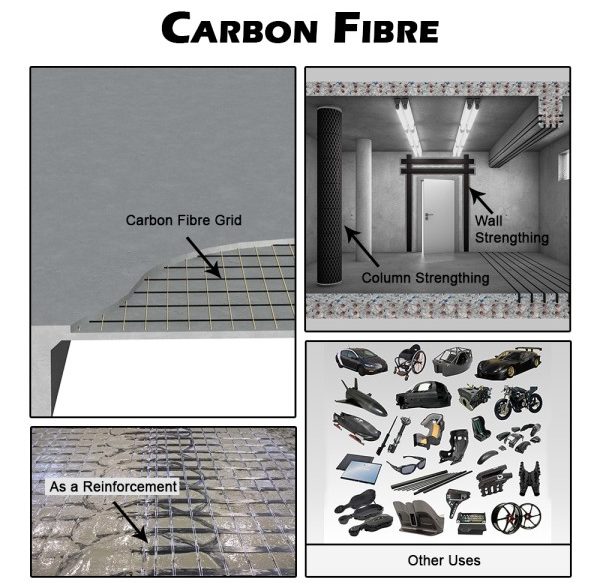

Uses of Carbon Fibre

Carbon fibre usage is growing in a variety of applications including aerospace, sporting goods, military, medical applications, automobile industry and commercial or industrial applications, where successful, carbon composites have lowered total system costs through reduced maintenance, faster processing speed and improved reliability.

01. Reinforcing the Structure

- Nowadays strengthening is one of the most common cases for using carbon fibres in building engineering.

- Carbon fibre is used as external reinforcement in the rehabilitation of reinforced structures. Applying Carbon fibre, as an external reinforcing allows avoiding installing the anchors involving significant volumes of material in work.

For Wooden structures:

- There are two methods for reinforcing. One is by gluing down on the surface and second is by pasting into the pre-made saw cuts. The second method is usually used when it is required to retain an initial look of the structure.

- External Reinforcing elements made of carbon fibres are used for sawn and laminated wooden beams.

- Textiles made of carbon fibre also known as carbon fibre textile can be used on the glue-laminated timber. Usually, textiles are used for gluing the wood laminates which help to retain the load-bearing capacity of the timber structure when making the holes and cuts.

- Fast and easy to install, are the main advantages of reinforcing wooden structure with carbon fibre as compared to traditional methods.

02. In Precast Concrete

Using carbon fibre in precast concrete is rapidly increasing. Now it is a prevalent material for precast elements in USA.

- A grid of carbon fibre is used in the panel faces to replace steel mesh reinforcement in the outer and inner sections of the concrete wall.

- Carbon fibre grid reinforcement in the wall panel face allows less quantum of concrete, which reduces weight and raw material usage. Replacing welded grid with carbon fibre grid in the slabs reduces weight and the need for chemical protection.

- Carbon fibre is used as a shear grid or truss to connect the inner and outer concrete surface of sandwich wall panels.

03. In Bridge Construction

- Carbon fibres are also used in bridge construction. According to ‘Litvinov Artem’ (Author of Applying Carbon Fibre in Building Structures), “Since 1992 there have been built several footbridges made from carbon fibre reinforced composites. Examples are the 40m span Fiber line Bridge in Denmark, 38m spans Lleida Footbridge in span and 56m span opening Fredrikstad Bridge in Norway.”

- In bridge construction, carbon fibre can be used in the main load-bearing structures, decking, cables and supports.

The carbon fibres are also used for manufacturing sports equipment like hockey sticks, Helmets, Tennis Rackets, Golf clubs, Track spikes etc. In medical application, it is used in some Hospital equipment’s. i.e. X-ray, surgical tables, stretchers and film cassettes etc. It is used widely in imaging equipment structures to support limbs being X-rayed or treated with radiation. Apart from that, it is used in making of Gear boxes of Railway Engines, Parts for airplanes, Telescopes etc.

Properties of Carbon Fibre

The features of carbon fibre are similar to steel and its weight is almost same as plastic. Let see the properties of carbon fibre.

01. The strength to weight ratio of Carbon fibre is high.

02. The density of carbon fibre is approximately 1600 kg/m3.

03. It has high Rigidity. In other words, it is very stiff. Carbon fibre is over 4 times stiffer than Glass and is almost 2.5 times stiffer than aluminum. The stiffness of carbon fibre is 26830 N/m.

04. It has higher Corrosion resistance.

05. It is chemically stable.

06. It is electrically conductive.

07. It possesses good tensile strength. Carbon fibre has a Tensile strength of approximately 4127 psi. (290 kgf/cm2)

08. It has high fire resistance.

09. Thermal Conductivity of carbon fibre is high. Thermal conductivity is a measure on how easily heat flows through a material. The thermal conductivity of Carbon fibre is 24.

10. It has low thermal expansion. Low efficient of Thermal expansion makes carbon fibre suitable for applications where small movements can be critical. Carbon fibre can have a broad range of CTE’s, -1 to 8+, depending on the direction measured.

Now that we have understood the properties and applications of carbon fibre, it equally becomes essential for us to understand the advantages and disadvantages associated with it. So let us go through the advantages and disadvantages of carbon fibre.

Advantages of Carbon Fibre

01. Carbon fibre has good strength and rigidity, mainly PAN-based fibre.

02. It is very lightweight and robust material.

03. It has an excellent thermal conductivity in the absence of Oxygen. Therefore, the quantity of heat can easily transmit through carbon fibre.

04. It is transparent to radiation and and invisible in X-rays.

05. It is an excellent conductor of electricity.

06. It has a longer working life and is exceptionally durable.

07. Due to corrosion resistance properties of carbon fibre, it has a long life in a corrosive environment.

Disadvantages of Carbon Fibre

01. It is a brittle material. When it is compressed beyond its strength, it will break or shatter.

02. It is an expensive material.

03. Sufficient care needs to be taken during handling of carbon fibre because it is electrically conductive and can cause destruction with electrical system.

04. The bonding between the fibres and material matrix may be difficult to achieve.

Conclusion

Carbon fibres are added in materials to form composites with improved properties. The addition of carbon fibres creates a composite that has outstanding mechanical properties, performs well in a high-temperature environment and possesses the benefits of durability.

There are many types of fibres used as reinforcement to increase the strength and other properties of the material. Carbon fibres are mostly used, where lightweight material for reinforcement is required. Future efforts are likely to focus on PAN based fibre with even better solidity and durability. Its newer applications are being explored in various fields.

Must Read:

Steel Reinforcement Types & Properties | All You Need to Know!

Pros and Cons of Steel Reinforcement Bars

Image Courtesy: Image 1

Author Bio

Arfa Falak – My name is Arfa Falak and I have my graduation in BE (civil). I live in Bangalore. I am an aspiring design Engineer.