A building construction is never done overnight. It involves lots of temporary phases. During the construction of the new buildings as well as during the repair of old or damaged buildings, various types of temporary structures are built by masons. These structures are called temporary because the structures get dismantled when their functions are over.

Although temporary, these structures are part of the construction and helps in safe progress at quick and uninterrupted pace. Without these temporary structures, it is not possible to construct a building flawlessly. In terms of functions, there are various types of temporary structures. Single scaffolding or bricklayer’s scaffolding is a single type of temporary structure.

According to ‘R. Chudley’ (Author of Building Construction Handbook), scaffolding is a temporary working platform, erected around the perimeter of a building or structure to provide a safe working place at a convenient height. They are mostly built when the working height or level of the construction is 1.5 m or more above the ground level.

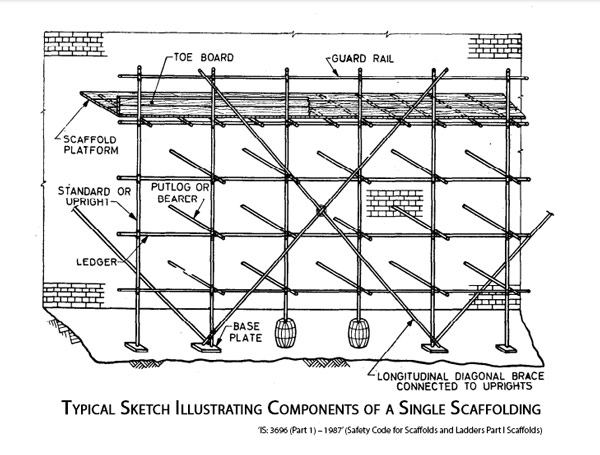

When the height of the column or wall or other structural components of a building exceeds the height of 1.5 m, temporary structures are needed to support the platform over which the workmen can sit and carry their work. These temporary structures, constructed very close to the wall, are in the form of steel or timber framework, commonly called scaffolding. A scaffolding structure is also needed for the repairs or even demolition of a building. The process should be stable and should be strong enough to support workmen and other construction material placed on the platform supported by the scaffolding. The height of scaffolding keeps on increasing as the height of construction/building increases.According to ‘IS: 3696 (Part 1) – 1987’ (Safety Code for Scaffolds and Ladders Part I Scaffolds), , scaffolding is a temporary structure consisting of standards, putlogs, ledgers, generally of bamboo, ballies, timber or metal to provide a working platform for workmen and materials in the course of construction. These structures contribute helps for carrying maintenance, repairs and demolition if any. Also scaffolding offers extra support for construction by arranging easy and hassle-free movement of workmen, maneuvering their tools as well as prompt and direct access to the construction materials.

There are various types of scaffolding processes practiced in market. Some of the most popular options are bamboo scaffolding, single scaffolding, double scaffolding, cantilever scaffolding, suspended/swinging scaffolding etc. Here we are going to discuss single scaffolding.

To know more about different types of scaffolding, see below article All the Basic Guide for Scaffolding!

Before knowing about single scaffolding, let us first know about the components of scaffolding.

Scaffolding Components are,

- Standards: These are the vertical members of the framework, supported on the ground or drums, or embedded into the ground

- Ledgers: These are horizontal members, running parallel to the wall

- Braces: These are diagonal members fixed on the standards

- Putlogs: These are transverse members, placed at right angles to the wall with one end supported on ledgers and another end on the wall

- Transoms: These are the putlogs whose both ends are supported on ledgers.

- Bridle: This is a temporary bridge a wall opening for the workmen; it is set in a way that supports one end of putlog at the opening.

- Boarding: These are horizontal platform to support workmen and material; these are placed on the putlogs for deriving stability and support.

- Guard Rail: This is a rail, provided like a ledger, at the working level.

- Toe Board: These are specially made small but sturdy boards, placed parallel to ledgers, and supported on putlogs. These are used to provide protection at the level of the working platform.

Various components or tools of the scaffolding system are secured by means of rope-lashings, nails bolt etc. so that the users can stay safe and on the control of his movements.

Single Scaffolding

It is also known as bricklayer’s scaffolding and it is the most common implemented process due to its inexpensive arrangement and simplicity of assembling and dismantling of the structures. In Asia including India, buildings are mostly constructed with brick masonry because bricks are cheaply available here and do not require highly-skilled masons to work with. For the construction of a building with brick masonry, usually single scaffolding is used.

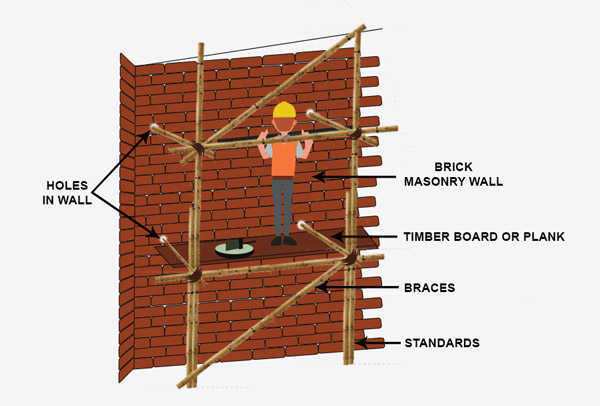

Figure below illustrates the construction of a typical type of bricklayer’s scaffolding. It is essentially made of vertical members known as standards, which are firmly embedded in the ground or in barrels filled with soil or sand.

The diameter of these standards is about 10-15 cm. and these structures are found placed at 1.0 m to 2.0 m. distance from the building in a row with 2.0 m to 2.7 m center to center spacing. In India for big and complicated structures mostly good quality Ballies are used for making standards. For constructing less complicated, single, or double story buildings at some places long thick Bamboos are also employed for making scaffolding support.

These standards are firmly interconnected by means of ledgers of thick bamboos fitted horizontally at 1.3 m to 1.6 m spacing. The transverse bearers (putlogs) are found placed with their one end on the ledgers and the other ends in the holes kept in the wall as shown in the fig.

In India, thick bamboos are employed as putlogs and placed at 1.0 m to 1.3 m apart. The outer end of it is kept firmly tied to the ledger. For safety purpose sometimes the inner ends, which are on the inner side of walls, are kept tied together by using another bamboo so that during traverse movements the scaffolding may not fall, acts unstable, or move away from the building from the top, which in any case may call fatal consequences.

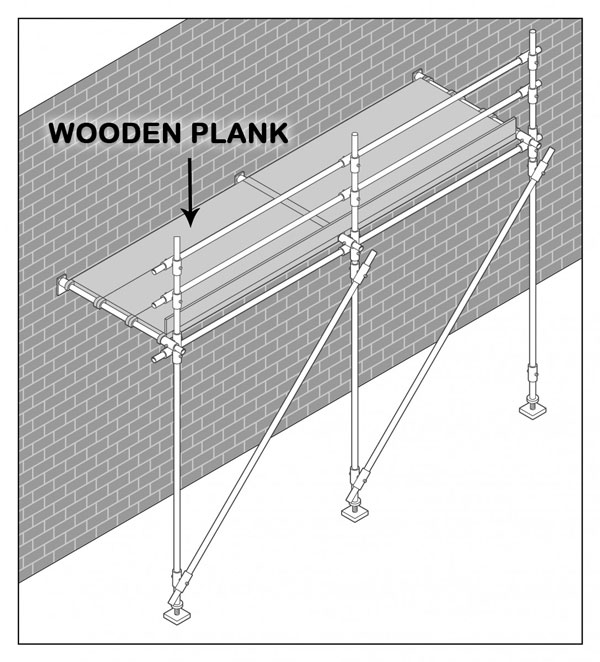

For keeping construction materials, tools and equipment at different elevations and at easy access of the masons, timber boards/wooden planks are placed over the putlogs as shown in the next fig. In India, bamboo ballies are also used at some places, but these are not somehow preferred these days. In case of lofty buildings, diagonal fixtures known as braces are used to get fixed to the standards and ledgers on the outer side to arrange more strength to the scaffolding structure.

At the construction site, the safety of workers is of the topmost priority. Thus, use of the best scaffolding has become mandatory for creating a protected and safe workplace for workers who work at heights throughout the building construction phase.

Hence, we can say that scaffolding has a vital role to play in a construction process. If the designs and erection of the single scaffolding are not done with proper care, the structure may collapse and may cause serious accidents. Another advantage of using scaffolding is that it offers a level and balanced working platform, which facilitates multiple workers to work on a site simultaneously. To carry out safe scaffolding work follow the guidelines suggested here.

In case of the single scaffolding one of the horizontal supports is always rested on the walls during wall construction while adding layer by layer vertically. The support remains on the wall till the construction of wall is completed. Hence when you remove this scaffolding you have to fill up the holes with the masonry very skillfully and carefully. Most of the time it is not done with due care and diligence due to which this point may become a messy source of leakage from the external walls. It is also observed that once such holes are filled up, hardly anyone cares to cure it with water, thus unintentionally they create a weaker joint. Hence if there is strategic importance of the building, it is advised to use double scaffolding, so that such holes are avoided and possibility of leakage can be skillfully eliminated.That simply explain what makes scaffolding an ultra-important part of skillful construction and ensuring safety at workplace. Although temporary but scaffolding should be done with best products and with paramount care. This is a way to keep workers safe and to stay safe from accidental and legal hassles for the owners during construction and in post-construction period.

Must Read:

Causes of Leakage in Buildings

30+ Guidelines for Constructing a Brick Masonry Wall