If you visit a construction site, you are more than likely going to see an image of a half-finished building with a number of workers doing work by standing on tall, steel or wooden structure. This structure is commonly known as scaffolding. It helps the workers to navigate around the building site and outline specific parts of a building project to make the job in hand easier. But why scaffolding is important during construction? Because the safety of the worker is topmost priority.

Scaffolds are widely used on construction site to get access to heights and areas that would be otherwise hard to get to or to reach for working. Scaffolds provide a working platform to workers. Sometimes, Unsafe scaffolding results in accidental death or cause of serious injury to those working on the scaffold or around areas where scaffolding is being used. So, it is must to follow the safety guidelines for scaffolding.

Guidelines for Scaffolding Safety

01. Safety training should be given to all the workers before scaffolding work is started to reduce the risk of an accident at the site

02. Scaffolding workers must always wear hard hats as well as be attached to a stable structure with a safety harness. They must also wear other safety gadgets like safety glasses, strong gloves, shoes with non-slip soles as well, and possibly ear protection.

03. To lower risk of accident, ensure that all workers are licensed.

04. Scaffolding should be strong and easy to maintain.

05. Inspect the scaffolding before and after use, in order to retain their structural integrity and safety.

06. During setting up and dismantling of scaffolds safety cordons, warning signs and other safety measures shall be provided to ensure safety.

07. For any overhead job at height of 2 meters and above, scaffolding with railing and toe-board shall be erected to provide working platforms. For any overhead job at heights 2 meters and above, it is mandatory to use double hook safety belt with fall arrester and safety nets in construction and maintenance activities

08. Base plates with a shank of minimum size 5 cm long for scaffolding shall be provided. The base plate should be of Mild Steel of minimum 5mm thickness and of at least 15 cm X 15 cm size.

Guideline for Design and Construction of Scaffolding

01. All scaffolds must be designed by a qualified person and constructed and loaded in accordance with that design.

02. The footing or anchorage for scaffolds shall be rigid, and capable of carrying its own weight and also maximum intended load without settling or displacement. It must be erected on solid footing.

03. Scaffolds and their segment must be capable of supporting without failure at least 4 times the maximum intended load. The intended load includes all workers, equipment, and supply loads. Scaffold structure framework also used structural design.

Also Read:

Big Mistakes that must be Avoided in Formwork while Concreting

Removal of Formwork: Know the Correct Time and The Precautions

Do’s

01. Scaffolding must be perfectly levelled in order to minimize the risk that workers can fall off and be injured or killed. Stay alert when on a scaffold, and watch balance at all times. Scaffolding should be properly supported on the wall.

02. Scaffolding should be erected under the supervision and direction of a competent person.

03. All materials for any scaffold shall be checked by a competent person on each occasion before and after using. A competent person should inspect the scaffolding and, at designated intervals, re-inspect it.

04. Slippery conditions on scaffolds should be eliminated immediately after they occur.

05. Cup-lock scaffoldings are best and most recommended for use. In case it is not possible to use cup-lock type scaffolding material, clearance shall be obtained from the engineer in charge to use other of steel scaffolding materials

06. Base plates with a shank of minimum size 5 cm long for scaffolding shall be provided. The base plate should be of Mild Steel of minimum 5mm thickness and of at least 15 cm X 15 cm size

07. The scaffold must be equipped with guardrails, mid-rails and toe boards.

08. The scaffold platforms must be tightly planked with scaffold plank grade material or equivalent.

09. The synthetic and natural rope i.e. coconut coir rope used in scaffolding must be protected from heat-producing sources.

10. Provide adequate lateral bracing at regular interval.

Also Read:

Things to Check Before Concreting Beams & Slabs

Things to Check Before Concreting Ground Beams & Plinth Beams

Don’ts

01. Unstableobjects i.e. boxes, barrels, loose bricks or concrete blocks, shall not be used to support scaffolds or planks.

02. Scaffolding should never be dropped in an uncontrolled way while dismantling the scaffold. All Scaffolding materials should be passed from hand to hand or raised and lowered in a controlled manner (light line or Gin Wheel & Rope etc.). The uncontrolled dropping or passing of any scaffolding materials should not be permitted.

03. Scaffolding structures are notoriously cramped, so it is crucial that tools are not left out and are put up neatly on the scaffolding itself. Keep all of the walkways free from obstructions and trash that might be become cause a fall or an accident.

04. Scaffolds shall not be altered or moved horizontally while they are in use or occupied.

05. Any damaged or weakened scaffold shall be immediately repaired and shall not be used until repairs have been completed.

06. Employees shall not work on scaffolds during storms or high winds or when covered with ice or snow unless all ice or snow is removed and planking is sanded to prevent slipping.

07. The scaffold will not be placed within 10 feet of an electrical power source (power lines, transformers etc.).

08. Tools, materials, and debris shall not be allowed to accumulate in quantities on platforms or around scaffold areas to cause a hazard.

09. Do not leave materials and equipment on the platform at the end of the day.

10. Overload on scaffold should be avoided.

11. Do not keep debris or unwanted materials on a scaffold where someone could trip over them or accidentally knock them off the platform.

12. No scaffold shall be erected, moved, dismantled, or altered except under the supervision of an authorized certifying engineer and by skilled workmen possessing adequate experience of such work under a valid permit.

Also Read:

Things to Check Before Concreting RCC wall (Shear Wall)

Things to Check Before Concreting Footings

Guideline for Suspended Scaffolding

01. Rigging on suspension scaffolds must be checked by a competent person before each shift.

02. It should also be checked by a competent person that after any occurrence that could affect structural integrity to ensure that all connections are tight and that no damage to the rigging has aroused since its last use.

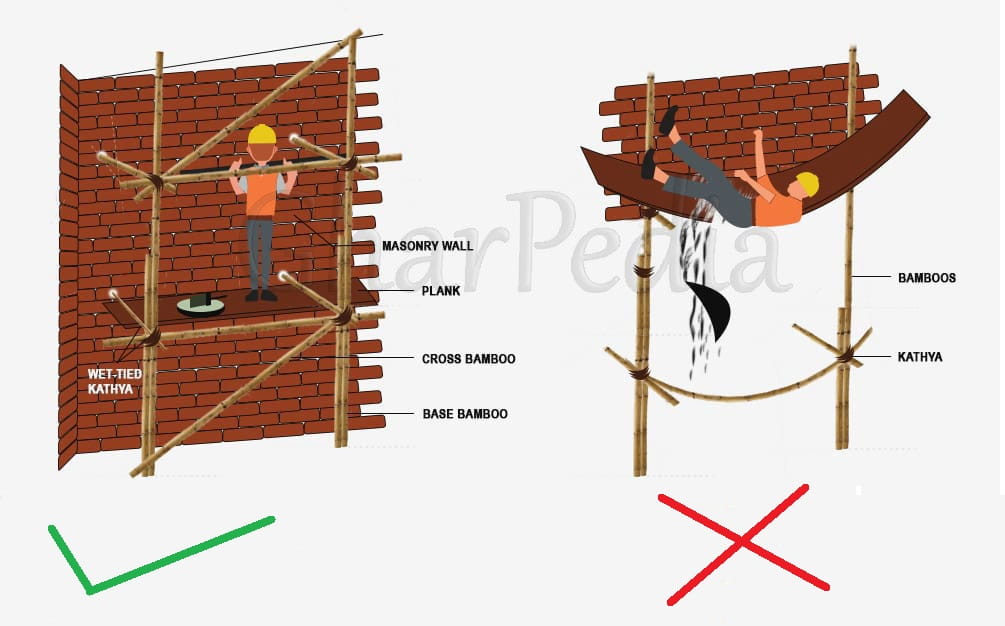

Guideline for Bamboo Scaffolding

01. Bamboo should be of good quality.

02. Bamboo should be straight.

03. Bamboo should be 3 to 5 years old and should be also air dried in vertical positions under the indoor condition for at least 3 months before using as scaffolding.

04. Coconut coir rope should be of good quality. It should not be too old. It should not be wet.

05. Bamboo should be tied tightly using coconut coir rope at joints. Change the coir rope in case duration for which scaffold has to be kept is more or it is stand by there since long or monsoon has passed.6. Bamboo should be checked at regular interval.

06. Bamboo scaffolding should not shake or vibrate during wind.

07. The external diameter of bamboo should not be less than 40 mm for Kao Jue bamboo and should not be less than 75 mm for Mao Jue bamboo. The minimum thickness of bamboo should be 10 mm.

Guideline for Any Steel Scaffolding

01. Steel scaffolding should be erected and used as per, manufacturer’s recommendations, proper seating, and locking of all connections using the corrective devices.

02. The scaffold should be accessed by using ladders and stairwells.

03. In the case of cup lock scaffolding, ensure that every lock of cup lock should be locked properly.

04. Avoid the use of the rusted component of scaffolding.

05. In the case of tubular scaffolding, do not use tubes which are bent.

06. In the case of braced scaffolding ensure that all bracing is secured properly. If bracing isn’t properly secured, scaffold movement may disconnect an end, which will reduce the stability of the scaffold.

07. In case of tube and clip scaffolding, ensure that all clamps are well clamped.

It is clear that scaffolding is a necessary part of the construction process, whether it’s about erecting high-rise buildings or carrying out the repairs and maintenance or periodical painting of any structure.

Scaffolding not only ensures faster completion of construction work, but it also guarantees the safety of workers and the public at construction sites. Safety of workers is very important at a construction site. To decrease the risk of an accident at the site, great care should be taken. So, make sure you hire a credible scaffolding contractor.

Also Read:

All About Plastering Work on Wall and its Precautions

Ready Mix Mortar for Brickwork, Plaster and Repair Maintenance!

Basic Guide for the Preparation of External Plaster!

Image Courtesy: Image 1, Image 2 – kabarnasional, Image 3, Image 4, Image 7 – industrytrainingservices