Construction aggregates or aggregates are the most mined materials in the world which are very much beneficial for the aggregates industry. Nowadays aggregates industries are growing in full phase as the uses of concrete has increased day by day. Experts are constantly discovering the new ways to make concrete durable for the high rise as well as homes.

The quality of the cement, aggregates and water (concrete ingredients) must be maintained to make the concrete durable. But sometime, the quality of concrete ingredients is compromised i.e. bulking of fine aggregates (sand), higher fineness of sand, deleterious substance in aggregates, etc. It may leads to decrease in the strength of concrete compare to its design strength. There are many other factors which are responsible to decrease the design strength of concrete.

As per the concrete expert’s opinion, bulking of sand is one of the critical factor which is responsible for the bad quality of concrete.

Do you Know What is Bulking of Sand?

Bulking of sand is the increase in the volume of sand due to the presence of moisture on the sand particles. The presence of moisture in aggregates cause the bulking of sand which may affects the design strength of concrete. The extent of bulking depends on the percentage of moisture present in the sand and on its fineness.

Therefore the bulking test is carried out before starting the concrete work to ensure that the volume of the sand is changed or not.

The bulking of sand test should be made at the

- Start of work

- Each new consignment of sand

- After any material has under gone the drastic weather change i.e. rain or hot

When sand is delivered and is used on the job, quite frequently it contains moisture which causes films of water to form on the surface of the particles, fluffing them apart. This is called bulking of sand and for moisture content of about 5 or 6 percent it may be as much as 20, 30 or even 40 percent depending upon the grading of the sand. Bulking of sand is more in fine sand than coarse sand. It is ideal to find out bulking of sand when we use volumetric batching of concrete to measure the sand and course aggregates (concrete ingredients).

Purpose of Bulkage Test

When we use fine aggregate (sand) to make concrete, it is necessary to know how much sand that you are using has bulked. This is determined by bulking test. This test is based on the fact that while damp sand bulks, the volume of saturated sand completely inundated with water is the same as if the sand were dry. Thus, you can measure volume of saturated sand and the result will be the same as that of dry sand.

Test Apparatus for Measuring the Value of Bulkage of Sand

To make the test you will require:

- Sample of sand

- Straight sided container such as a 1 kg jam jar, or a clean empty cane

- Steel measuring rule

- 6 mm dia Steel rod

- Second container to dip it into, and some water.

Test Procedure for Bulking of Sand

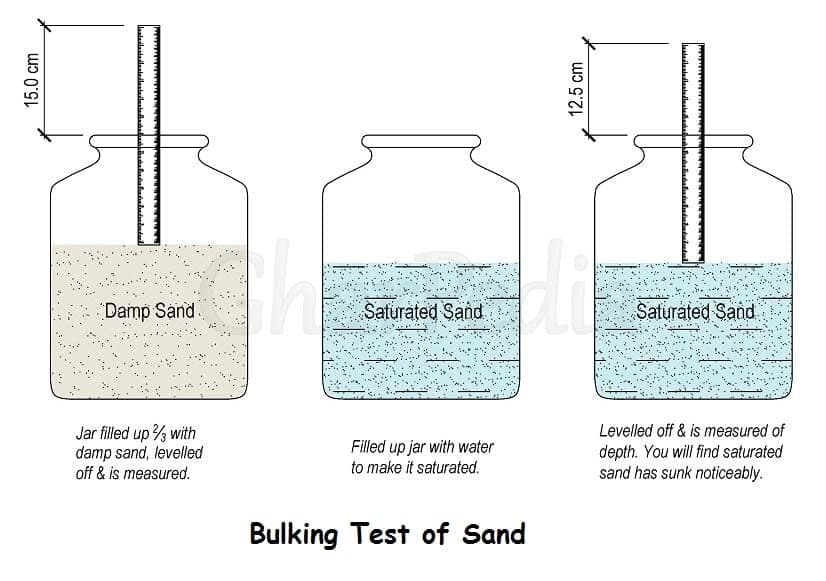

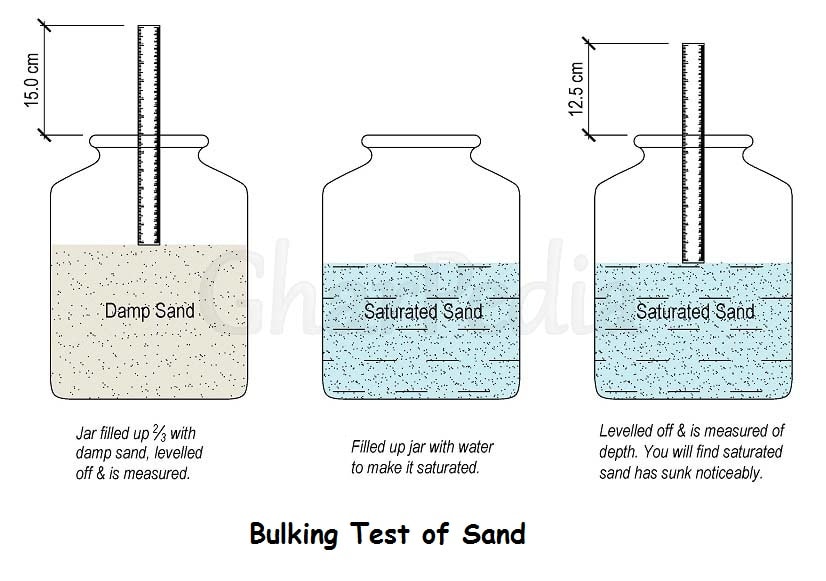

First fill the container about two-thirds full with the sand you are testing. Drop it loosely, do not pack it.

Level off the top of the sand and pushing the steel rule down through the bottom, measure its height. Suppose it is 15 cm.

So now you know the height of the damp, bulked sand. Next step is to find the height of the same sand when saturated with water. You can then compare the two.

Empty the sand in the other container, taking care to see that none of it is lost in the process, and half fill the first container with water. Now put the sand back into the water, bit by bit, so that it is entirely saturated.

First put back about half the sand and rod it thoroughly to remove any air. Then add the rest and rod again in the same way and level off top. Now push your rule through the sand as before and measure the new height then it is find that it has sunk noticeably. Say it now measures 12.5 cm.

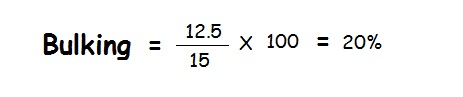

Calculation:

Result shows that when sand saturated, it is bulked to 15 cm. Therefore bulking is 2.5 cm on 12.5 cm of dry sand and that is to say 20 percent.

In gauging sand for the mix, therefore you should add 20 percent more sand than that quoted in the specification or as suggested in concrete mix design.

Suppose the mix specified is 1:2:4, then the actual quantity of sand to be used will be 1.20 X 2 = 2.4 litres giving a field mix of 1:2.4:4.

If you neglect to make this correction for bulking the actual dry sand measured will be X 2 = 1.67 litres. The mix will then be 1:1.67:4 in terms of dry sand.

This reduction in the ratio of sand causes a reduction in the quantity of concrete produced with each bag of cement, and in most cases there will be insufficient fine material to give a workable mix which can make concrete with voids their by reducing its strength and durability both. It may be noted that coarse aggregate is little affected in volume by moisture.

Practically it has been seen that bulking of sand increase up to 30% by volume and up to 5% by weight. If more water is added the film around the sand particles is broken and the volume of sand comes to its original dry volume, and the water comes at its surface. Thus it is important that the volume of dry as well as wet sand is the same. The volume of moist sand is only more.

Must Read:

What is the Concrete Slump Test?

Ways to Check the Quality of Sand at Site!