The discovery of cement has revolutionized the construction industry and has added lots of new dimensions to construction. It has made many new things possible which were considered impossible until few years ago. However, it is not a simple material. You have to understand its complex properties and terms without which you cannot reap full benefits. For example, do you know what is the difference between setting and hardening? Let us discuss the same here to help you understand it in simple terms.

Cement is an essential building material. And plays a major role in the strength of the concrete construction. There are many factors affecting the strength of concrete, but the most critical one is the cement. Concrete is a mixture of cement, sand, aggregate, water and admixtures etc. When cement is mixed with water, a chemical reaction takes place called hydration. Hydration is responsible for the setting as well as the hardening of cement mortar/concrete. Setting is quite different from hardening. In this article, we have mentioned differences between setting and hardening of cement/concrete.

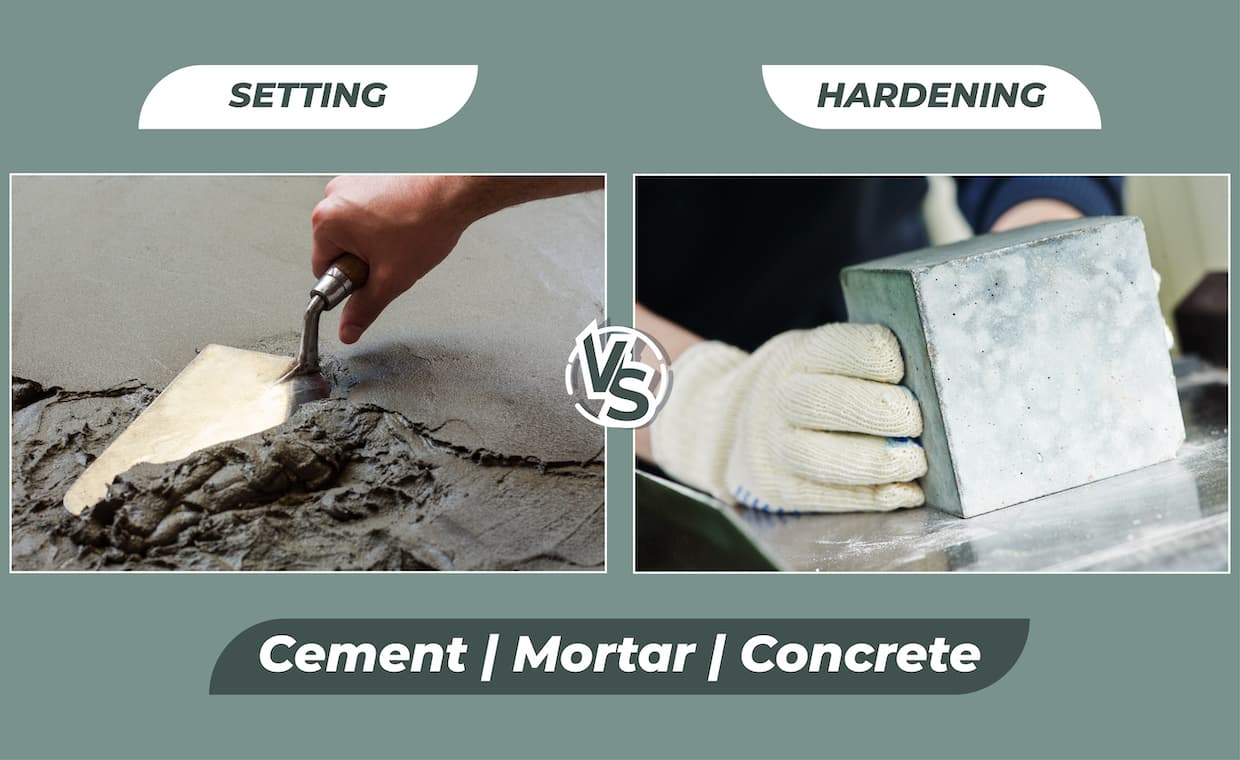

Differences Between Setting and Hardening of Cement/Concrete

Followings are the differences between the setting & hardening of cement/ mortar/concrete and details of their mechanisms, testing and factors affecting it.

01. Definition / Description

Setting of Cement / Mortar / Concrete

- The term ‘Setting’ is used to define the stiffening of the cement paste as well as concrete or mortar. The setting of cement refers to transformation from liquid to plastic state and further plastic to a solid state. In the setting process, the surface of cement or mortar or concrete becomes sufficiently rigid to withstand a certain amount of pressure but still contains some moisture within the mixture. Hence, during setting, cement/mortar/concrete does not gain considerable strength.

- In other words, the setting of cement/mortar/concrete is a stage in which it achieves stiffness to retain its shape in accordance with the support inside in which it is moulded.

- There are two stages of setting: Initial setting and final setting.

01. Initial Setting is when the cement or mortar or concrete starts to lose its plasticity.

02. Final Setting is when the cement/mortar/concrete completely loses its plasticity.

Hardening of Cement / Mortar / Concrete

- The term ‘Hardening’ is defined as the strength gain of a set cement or mortar or concrete., Even during the hardening the cement/mortar/concrete continue to acquire some strength, however, hardening happens after the setting state.

- In other words, hardening of cement as well as mortar or concrete is the stage when the mixture gains strength or the development of the strength, only after which, it can carry the intended loads.

- In the process of hardening, a useful and measurable strength gets developed.

02. Importance

Setting of Cement / Mortar / Concrete

- Knowledge regarding setting time is of utmost importance because it gives an idea about the construction procedures.

01. Initial setting time gives an estimate on how long the cement as well as mortar or concrete can stay in the plastic state so that the transportation, placement and finishing can be done easily within the specific timeframe and necessary arrangements can be done.

02. Final setting time predicts how long the cement or mortar or concrete will take to set and become stiff enough to retain the shape, so that, the formwork can be removed. If you remove the formwork during the setting stage, it may develop internal cracks and deformation begins and appears on the surface due to lack of stiffness.

Hardening of Cement / Mortar / Concrete

- After hardening, cement or mortar or concrete can stand without crack and deformations, and strength can be measured.

- It gives the idea about the beneficial/useful service life of the concrete structure and whether desired strength is achieved or not etc.

03. Mechanisms of Setting and Hardening

The setting of cement or mortar or concrete is the result of hydration which is the reaction occurring between the cementitious material and the water. Hydration is an exothermic process; which means that during hydration some amount of heat is produced which is known as heat of hydration.

According to ‘A.M. Neville’ Honorary Member of The American Concrete Institute, when water is added into the cement, hydration immediately starts and four compounds of cement (C3S, C2S, C3A, C4AF) get hydrated and forms a gel (C-S-H: Calcium Silicate Hydrate) which is the complex compound form of hydro silicate crystals.

The gel gradually thickens and act as glue around other particles. Thus, the cement starts setting. And after that, it starts to gain strength and this may continue for weeks or months after the cement or mortar or concrete has been mixed with water and implanted.

Also Read:

Different Methods for Mixing Concrete

Methods of Placing of Concrete for Various Situations & Locations

04. Time

Setting of Cement / Mortar / Concrete

- As per the ‘Indian standard specification (IS 269-1989)’, initial setting time of ordinary cement should be not less than 30 minutes and final setting time of ordinary cement should be not more than 600 minutes.

- As per the ‘A.M. Neville’ Honorary Member of The American Concrete Institute, a minimum time for the initial set of 45 minutes, and limits on the final setting time no longer appears in the ASTM standards.

But, the initial setting time and final setting time of cement depends on various factors like types of cement, temperature, weather condition, fineness of cement, amount of water, use of admixtures etc.

Hardening of Cement / Mortar / Concrete

- According to experts, it generally takes five to seven days for the concrete to complete the hardening process.

- Hardening of cement is a long-lasting process. This process may continue for more than a year and even after a year.

05. Testing

Setting of Cement / Mortar / Concrete

- To know the setting time of cement, the setting time test is conducted. Initial setting time test and final setting time test of cement are generally conducted.

- Vicat apparatus is used to perform these tests for cement.

Hardening of Cement / Mortar / Concrete

- To know the hardening of cement, the compressive strength test of cement is conducted.

- Compressive testing machine or universal testing machine and cube moulds are used to perform this test.

06. Admixtures for Setting and Hardening

The accelerating admixtures or concrete accelerators can accelerate the hydration, setting time and the hardening of cement. Concrete accelerators such as calcium chloride, Triethanolamine, sodium thiocyanate, calcium formate, calcium nitrite etc. are used.

As against that, the retarding admixtures or concrete retarders can delay the hydration, setting time and hardening of cement. Concrete retarders such as hydroxylic acid, lignin, sugar, lignosulfonates etc. are generally used.

07. Factor Affecting Setting and Hardening

01. Chemical Composition of Cement:

The mineral composition of cement and their ratios are the significant factors affecting the setting and hardening of cement because it will reveal different characteristics when reacting with water. Such as, the increase in the amount of C3A can speed up the setting and hardening rate of cement.

02. Fineness of Cement:

The fineness of cement particles directly affects the hydration, setting and hardening, strength and heat of hydration. If the cement particles are fine, they have a large surface area available for contact with water. Hence, the hydration will be more and quick, and hence, the setting and hardening will be accelerated correspondingly, and the early strength will be high.

03. Conditions of Curing:

The curing environment like sufficient temperature and moisture encourages the setting and hardening process of cement and the development of the early strength. If the moisture in the environment is less, the water will evaporate and lead to insufficient hydration and decrease the setting and hardening.

04. The Mixing of Water Content:

If the amount of cement remains unchanged while the water content increases, it will enhance the amount of capillary pores and it will extend/retard both the setting time and the hardening of cement/mortar/concrete.

05. Admixture:

Hydration, setting, and hardening of cement are constrained by cement components like C3S and C3A including assorted admixtures which effect hydration of C3S and C3A. Hence, it can change the hydration as well as the setting and hardening of cement.

Conclusion

Summing up, the setting time and the hardening of cement/mortar/concrete are therefore the most essential properties. One needs to understand these fully, to handle concrete, either while placing, or during work, or to maintain the important timings of concreting processes, such as transportation and placing time of concrete, formwork side removal time and removal of props etc. These are the key decisions which affect the quality and durability of the structures as well as govern the time for completion.

Also Read:

Field vs Laboratory Testing of Cement

Different Methods of Curing Concrete: Know Before Curing

11 Best Methods for Transportation of Concrete