Table of Contents

Nowadays the construction industry is at its peak with new emerging technologies. Concrete is an essential material for the construction industry. Concrete is made by mixing of cement, sand, coarse aggregate and water. It’s either nominal mix or design mix. Concrete can be designed to achieve the desired strength of concrete according to the requirement of structure.

As one knows, the concrete is mainly designed to resist compression and not for direct tension. But the knowledge of tensile strength is also important for estimating the load under which cracking will develop in concrete.

The absence of cracking is considerably important in maintaining the continuity of reinforced concrete structures and in the prevention of corrosion of reinforcement. Like the reinforced concrete, tensile strength is not negligible in the unreinforced concrete structures such as dams, under earthquake conditions. Other structures like highway and airfield pavements are designed on the based on flexural strength, which involves strength in tension. Hence it is necessary to conduct flexural strength test to know the strength of such structures.

What is Flexural Strength of Concrete?

Tensile strength of concrete is measured indirectly by the flexural test. The flexural test shows the ability of unreinforced concrete beam or slab to withstand failure in bending. Flexural strength signifies the highest stress experienced within the material at its moment of rupture. Flexural strength is also known as bend strength, fracture strength and modulus of rupture.

Standard Guidelines for Flexural Strength Test of Concrete

- IS: 516-1959

- ASTM C 78-09

- BS EN 12390-5: 2000

Here, Flexural strength test is described as per the IS: 516 – 1959

Test Apparatus and Material Required for Flexural Strength Test

(a) Apparatus for Flexural Strength Test:

01. Flexural Testing Machine:

- Supporting Roller: The bed of the flexural testing machine is provided with two steel rollers of 38 mm in diameter, which works as a support for the concrete specimen. These rollers are mounted at the 600 mm center to center distance for 150 mm specimens or 400 mm center to center distance for 100 mm specimens.

- Loading Roller: The load is applied through two similar roller which is mounted on the supporting span at the 200 mm center to center distance for 150 mm specimens or 133 mm center to center distance for 100 mm specimens. The load is divided equally between the two loading rollers and all rollers are mounted in such a manner that the load is applied axially and without subjecting the specimen to any torsional stresses or restraints.

02. Test Specimens:

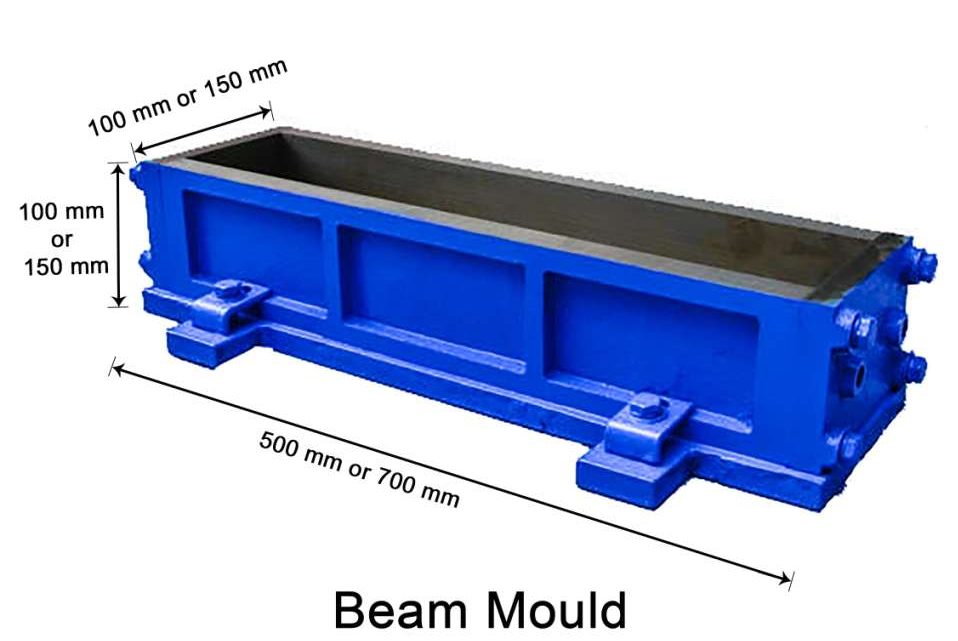

Concrete beam mould of size,

- 150 mm * 150 mm * 700 mm or

- 100 mm * 100 mm * 500 mm.

03. Vibrating Machine

04. Weighing Machine

05. Gauging Trowel

06. Measuring Cylinder

07. Curing Tank

08. Tray(b) Material Required for Flexural Strength Test: Ingredients like cement, sand, aggregate and water are required according to the concrete mix design.

Test Procedure for Flexural Strength Test

01. Mixing of Material

- The watertight and non-absorbent platform and other tools like shovel, trowel etc. are used for the mixing of the concrete batch.

- Firstly, cement and sand (fine aggregate) are mixed in a dry condition till the mixture properly blends and gets a uniform colour. Then the coarse aggregates are added and mixed until coarse aggregates are uniformly distributed throughout the batch.

- After that, water is added according to water-cement ratio and the whole batch is mixed till the concrete appears to be homogeneous and gets the desired consistency.

- Above described procedure is for hand mixing of concrete batching, you can also use machine for mixing. To know more about methods for mixing of concrete than refer the various methods for mixing concrete.

02. Preparation of Test Specimen (Beam Mould)

- First, clean the beam mould and apply the lubricant like oil on the inner surface of the beam mould.

- Concrete is placed in the beam mould in three layers of equal thickness and concrete should be stroked 35 times per layer with the use of tamping steel rod and then compacted by vibration with using a vibrating table.

- Then finish the top surface of the beam mould by smoothing the surface with the blade of a trowel.

- The test specimens are to be stored in the fresh clean water at the temperature of 24°C to 30°C and beam should be tested immediately on the removal from the water whilst it is still in a wet condition.

03. Procedure for Testing of Test Specimen

- Take the dimensions and weight of the beam.

- Clean and wipe the bearing surfaces of the loading and supporting rollers and remove any loose sand or other material from the beam where it is to make contact with the rollers.

- Now, place the test specimen in the flexural testing machine in such a manner that the load can be applied to the uppermost surface as cast in the beam, along two lines spaced 200 or 133 mm apart.

- The axis of the specimen should be carefully aligned with the axis of the loading device.

- Apply the load gradually and continuously at the rate of 400 kg/minute for 150 mm specimen and 180 kg/minute for 100 mm specimen until the test specimen fails.

- Record the load at which the beam is failed.

- Note down the appearance of the fractured faces of concrete and any unusual features in the type of failure.

Flexural Test on Concrete Beam

Result Calculation of Flexural Strength Test of Concrete

The flexural strength is also expressed as the modulus of rupture (fb),

a = Distance between the line of fracture and nearer support, measured on the center line of the tensile side of the specimen.

p = maximum Load (kg)

l = supported length (cm)

b = width of specimen (cm)

d = failure point depth (cm)

01. If the a > 20 cm for 15 cm specimen or a > 13.3 cm for 10 cm specimen than,

fb = pl/bd2

02. If the a < 20 cm but > 17 cm for 15 cm specimen or a < 13.3 cm but > 11 cm for 10 cm specimen than,

fb = 3pa/bd2

03. If the a < 17 cm for a 15 cm specimen or a < 11 cm for a 10 cm specimen than results of the test should be discarded.

Points to be Taken Care of

- The test specimens should not become dry at any time until they have been taken out and tested.

- Test specimen should be carefully aligned and no packing should be used between the bearing surface of the test specimen and the rollers.

- The load should be applied without shock and increasing gradually as per loading rate.

- If there is any visible or noticeable defect in the beam than do not consider those test specimens.

Recommended Result of Flexural Test

Flexural strength or modulus of rupture is about the 10 to 20 % of compressive strength of the concrete and it depends upon the type, volume and size of coarse aggregate used in the concrete.

Flexural strength test measures the indirect tension in concrete. It helps in the designing of the structural components such as beams, shafts, cantilevers etc. and a useful tool to predict the durability of the structure.

Also Read:

In-Situ Concrete Pull Out Test for Compressive Strength

Hardened Concrete Core Test for Compressive Strength

Penetration Resistance Test for Concrete Compressive Strength

Does Rebound Hammer Test Results give Exact Concrete Strength?