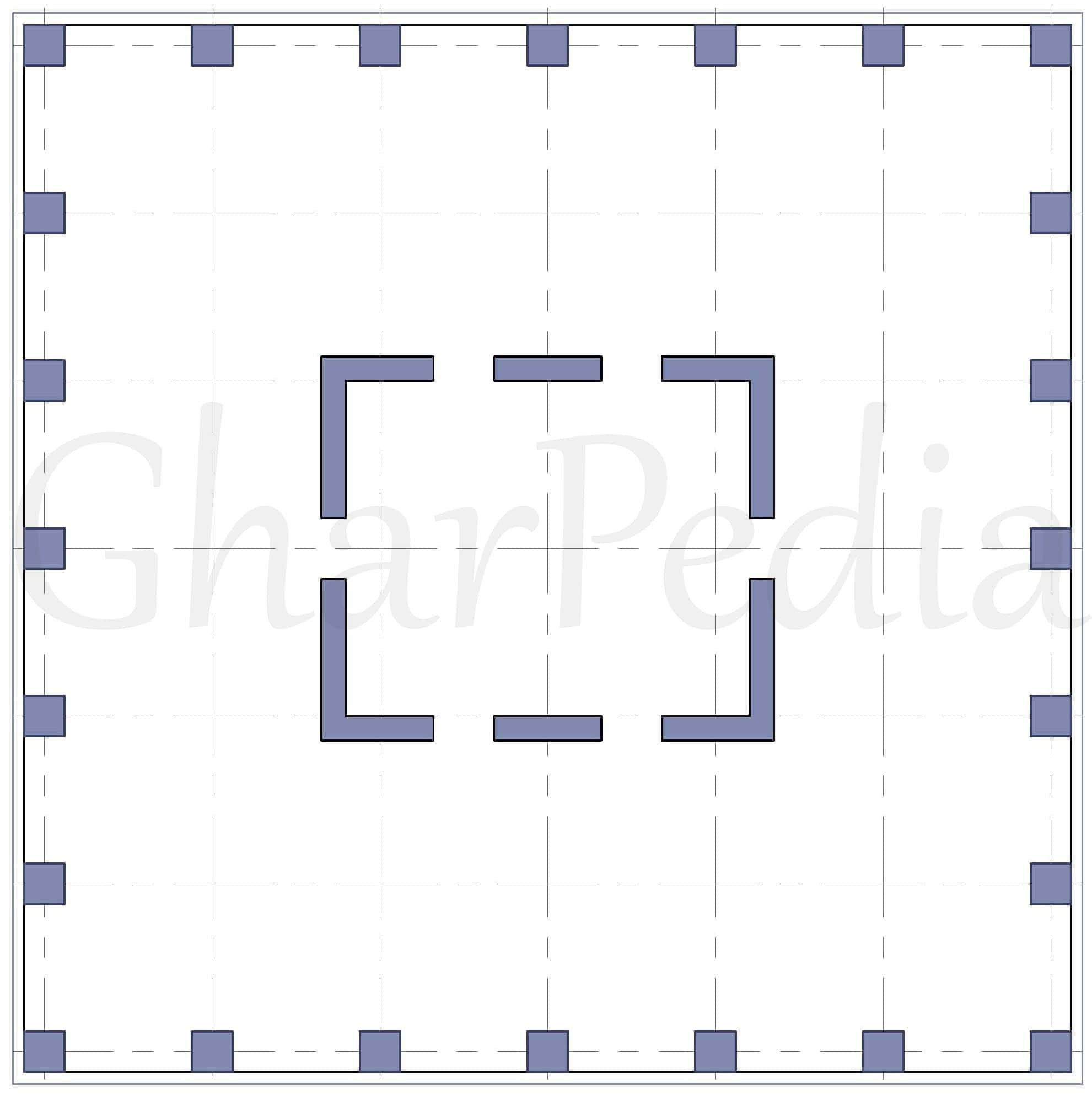

Maximum Efficiency of the entire structure for lateral strength and stiffness can be achieved only by making all column elements connected to each other in such a way that the entire building acts as a hollow tube or rigid box cantilevering out of the ground. Such a system is called Framed Tube System. This system is efficient for building high rise structures.

This system was originally developed for rectangular plans, it is now used for different shapes and sometimes used for circular and triangular plans too. The tube frame consists of closely spaced columns, 2-4m between centers, joined by deep girders. This will create a tube that will act like a continuous perforated chimney or stack.

In this system overturning resistance as well as overturning stresses in the columns would be direct tension or compression without any bending. The lateral resistant of frame tube system is provided by very stiff moment resistant frames which form a “tube” around the perimeter of the building.

The gravity load is shared between the tube and interior column or walls. The panel normal to the direction of the wind is considered as flange and the panel perpendicular is considered as web of the cantilever. When lateral loads act, the perimeter frame aligns in the direction of load and acts as a web. This system is most efficient in rectangular plan building.

Development of Tube Frame System

The inefficiency of the frame tube system for reinforced concrete buildings is useful when high rise building is to be constructed and designing through conventional framed system results in member proportions of large sizes and structural material cost increases too and thus this system becomes economically not viable.

This system was first used in Chicago’s DeWitt-Chestnut apartment building and completed in 1965, but the most notable example is the original World Trade Center Towers or Twin Towers.