The advancing world as it is today, the materials used for insulation are sweepingly trending in terms of acoustics, heat, etc. These form an enhancing part of comfort in the exteriors, interiors, as well as décor. Glass wool is one such insulating material bearing varied applications in homes, be it a part of roofs, false ceilings, or drywalls. According to ‘John Wiley & Sons‘ (Author of Webster’s New World College Dictionary), ‘Glass wool are fine fibers of glass intertwined in a woolly mass, used in filters and as insulation.’

What is Glass Wool?

Glass wool is manufactured from borosilicate glass with significant constituents such as silica sand, recycled glass and fixing agents. Glass wool is an insulating material constituted with melted glass as raw material. According to ‘Haimei Zhang‘ (Editor of Building materials in civil engineering), ‘Glass wool is a fibrous material made from the melted glass raw materials or cullet. It is available in two categories: loose wool and superfine wool. The loose yarn is used to make asphalt-bonded glass blanket and glass wool board. Additionally, it is used to preserve heat in the exterior-protected construction and the pipelines.’

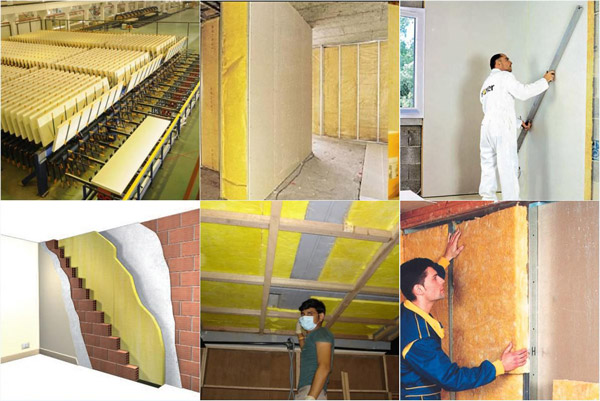

Glass Wool Production

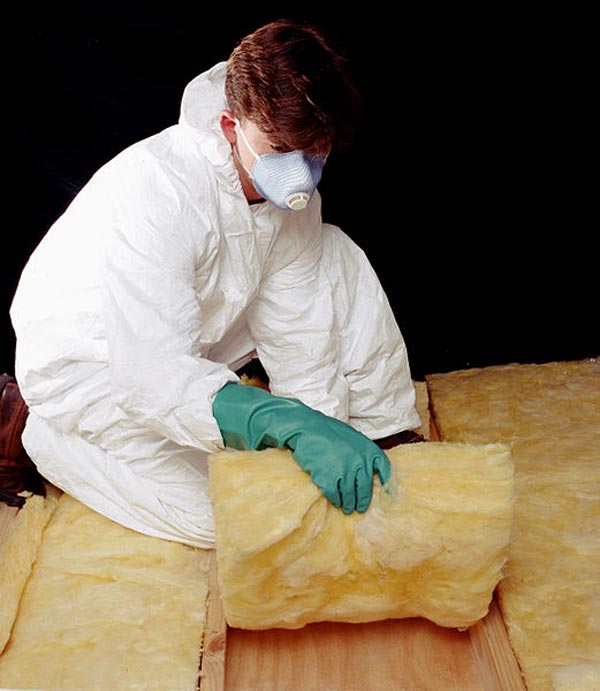

Glass wool is created from a thick layer of glass fibers that are cured in an oven at 200°C to bind the strands together and thus reduce the thickness of the sheet. Additionally, it is melted to 1100°C in an electrical furnace and later conditioned in a gas-fired furnace. It is a furnace product made from molten glass. From this melted glass, fibers are spun. This process includes rotating the fused glass in a high speed similar to the methodology used in production of a candy. In the process of spinning, the binding agent is blended into it. No CFCs or HCFCs are developed in the production process. The fibers are gathered in a mat form in a collection chamber and then transferred to an oven where it is cured under controlled conditions to the desired thickness and density. It is tailor-made in rolls or slabs. Likewise, it is also used as a component which is sprayed or applied on the surface to be insulated. It is a versatile material used for the insulation of walls, roofs, and floors. During installation, glass wool should be kept dry at all times because an increase in the moisture content may lead to a significant rise in thermal conductivity.

Also Read:

Basic Information of Roof & Its Functional Requirements

Roof & Its Classification

Once the production process is at a close, it is wrapped in roll or bat form. It can get compressed by a factor of up to 10 which saves the storage and reduces transportation costs. It is ideal to meet the demanding requirements, offering benefits in thermal insulation, fire safety and ease of installation.

Characteristics of Glass Wool

- It is fire-resistant till 300°C.

- It has excellent tensile strength.

- It is used as hollow walls and drywall insulation.

- Additionally, it is also used for roof insulation in auditoriums and suspended ceilings.

- It prevents heat loss, especially in HVAC ducting systems.

- It is an excellent sound insulator and used as acoustic barrier in partitions that prevent sound transmission.

Why Choose Glass Wool?

- Its products are non-combustible and positioned for operating temperatures up to 300°C.

- It is made up of 80% recyclable materials.

- It is lightweight and easy to install.

- It does not promote mould growth or vermin infestation.

- It possesses no health hazards.

- It is non-corrosive to metal.

Applications of Glass Wool Insulation

Glass wool applications include structural insulation, pipe insulation, filtration and soundproofing. These are manufactured to insulate products and applied in multiple areas of buildings. Moreover, Glass wool is the most common source of insulation in ceilings of residential buildings, and also has the following applications:

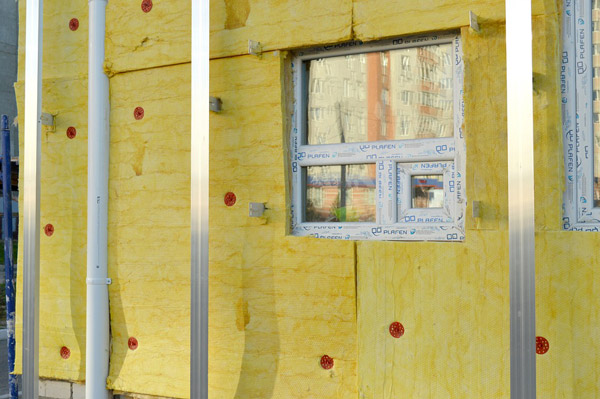

01. Cavity wall and Drywall Insulation

These are developed for insulation within steel frame structures, timber frame buildings and drywall systems. It is manufactured using high-quality glass wool and is glass tissue faced on one side for the ease of handling, and enhanced rigidity.

Applications in Drywall:

- Steel frame buildings

- Timber frame structures

- Drywall systems

- Designed for use in cavity walls but may effectively be used on top of ceilings, along with the roofline, or within masonry wall cavities

Also Read:

Gypsum Board: All You Need to Know!

Types of Gypsum Board | All you Need to Know

Application of Glass wool as an External Wrap:

- HVAC and air-conditioning system insulations: Duct wrap is a thermal insulation blanket specifically designed to wrap around air conditioning ducts

- External wrap around metal air-conditioning ducts: Rectangular and round heating, ventilation and air-conditioning systems.

Tips to Ensure the Good Ventilation in Home!

02. Pipe Insulation

Pipe insulation for hot and cold pipes.

This insulation is a pre-formed, rigid, resin bonded glass wool section of 1 meter in length. A single longitudinal slit allows the part to open to surround the pipe and snap it closed after placement. Standard finishing options are available in canvas, plain, and reinforced foil.

03. Over Purlin Insulation in Commercial Buildings

Factory board is a rigid board manufactured from non-combustible glass wool insulation. It is generally used as a multi-purpose wall cladding as well as over purlin roof insulation. It is available in 25, 40 or 50mm thickness.

04. Suspended Ceilings

The ceiling tiles are manufactured from non-combustible inorganic glass wool and bound with an inert thermosetting resin binder. A decorative vinyl facing is available in coral, for a durable finish.

Applications of Glass wool as Suspended Ceilings:

- Suspended ceilings: Domestic, Commercial, Industrial

- Suspended ceilings in commercial buildings such as cinemas, home theaters, recording studios.

05. Industrial Roof Insulation

This has been made from high quality non-combustible flexible material. Glass wool insulation with an inert binder makes the product lightweight, safe and resilient. It is facing one side with either a reinforced foil or white metalized foil. It is applied on both sides upon request.

06. Higher Temperature Insulations

It is manufactured from non-combustible glass wool, bonded with an inert thermosetting resin to form a hard and resilient product. It is odourless, inert and fully compatible with all standard building materials.

Glass wool as Thermal and Acoustic Control:

- A range of glass wool batts and blankets for thermal and acoustic control used in commercial buildings.

- Industrial thermal insulation for applications up to 450℃.

- Conservation and control of heat in boilers, tanks, ductwork, ovens, etc.

- Acoustical correction in compressor houses and machine rooms.

07. High Performance and Sound Proofing

The ceiling tiles are manufactured from non- combustible inorganic glass wool and bonded with an inert thermosetting resin binder. The flooring, surfaced with a black non-woven glass tissue for favorable sound absorption. It is not only used in commercial buildings such as cinemas where great soundproofing performance is required, but also used in other areas where optimal sound absorption is needed. Put to application as glass wool boards, which in turn transforms into home theatre insulation.

Summing up, glass wool is an insulating material having varied applications in homes as a part of roofs, false ceilings, drywalls, home theatres, etc. It is widely used for its known benefits in insulation, fire safety and ease of installation.