Shelter is one of the three basic needs of man along with food and clothing. The prehistoric man lived in caves, and later, he began constructing walls from the mud. In due course of time, many techniques for the masonry were developed and it became a structural part of the shelter. In early days, burnt brick masonry and stone masonry were popular. Now, with growing demand for construction, cheaper and faster techniques and materials are the need of the hour.

Concrete blocks are one such construction materials which help in achieving cheaper as well as faster construction than conventional bricks. The concrete blocks are available in two variations. 1) Solid concrete blocks and, 2) Hollow concrete blocks. In this article we are discussing both the varieties, yet, latter in more detail. The article deals with what hollow concrete blocks are, their pros and cons, properties and various types.

What are Concrete Blocks?

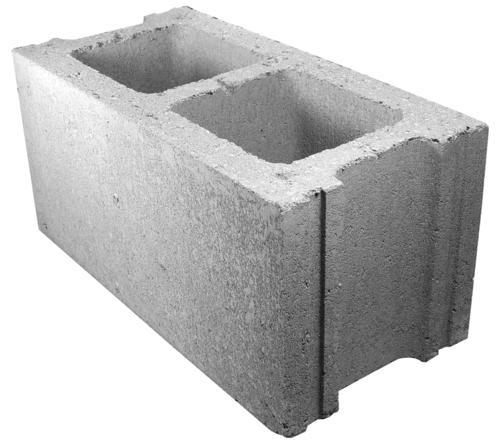

Concrete blocks are rectangular concrete masonry units either, solid (other than units used for bonding, such as a half-block) or hollow (open or closed cavity). Concrete blocks come in modular sizes and vary by country. Yet, their size and mass will be such that one can handle them easily. Moreover, to avoid confusion with slabs and panels, the height of the blocks should not exceed either its length or six times its width.

Two Major Types of Concrete Blocks or Concrete Masonry Unit

As mentioned above there are two major types of concrete blocks,

01. Solid Concrete Blocks

02. Hollow Concrete Blocks

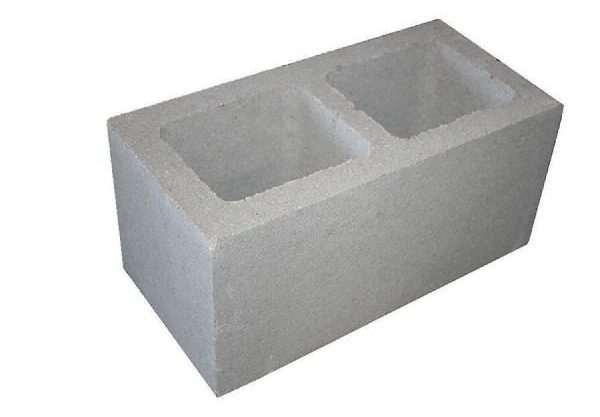

01. Solid Concrete Blocks

Solid concrete blocks are made from aggregate, Portland cement and sand. These blocks have a solid material, not less than 75% of the total volume of the block calculated from the overall dimensions. Hence, they are heavy in weight. These blocks provide good stability to the structure. So, these blocks are used for a large work of masonry. They are used in the load-bearing walls as well as the non-load bearing walls. Solid blocks are available in large sizes as compared to the conventional bricks. Therefore, less time is required to construct concrete block masonry than brick masonry.

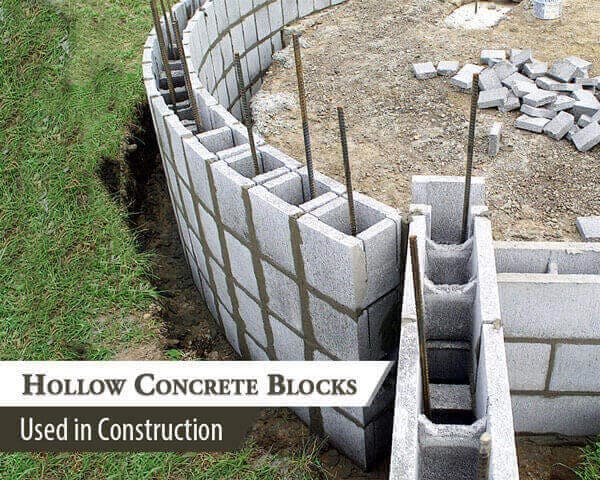

02. Hollow Concrete Blocks

They are the standard sized rectangular hollow blocks made of cast concrete of high or low density. For high-density blocks, Portland cement and aggregate, usually sand and fine gravel are used as a raw material. For low density blocks, industrial wastes, such as fly ash or bottom ash are used as the primary raw materials and are often called cinder blocks /breeze blocks in different parts of the world.

As per the definition given in the ‘Indian Standard – IS 2185 (Part-1) 2005’, hollow concrete blocks are having one or more large holes or cavities which either pass through the block (open cavity) or do not effectively pass through the block (closed cavity) and having the solid material between 50 and 75% of the total volume of the block calculated from the overall dimensions. These holes or cavities reduce the total cross-sectional area of the block and hence the weight of block structure as a whole.

Hollow concrete blocks are more commonly used in masonry construction. It accelerates the construction process, saves cement and steel and reduces the work expenses at the construction site. These blocks lower the natural weight of masonry constructions and improve the physical properties of walls, such as noise and thermal insulation. They also provide facilities for concealing electrical conduit, water and soil pipes.

Size of Hollow Concrete Blocks

Standard hollow concrete blocks are available in full size as well as half size. Full-sized blocks are rectangular and have two cores while half-sized blocks are cubical and contain one core.

According to the ‘Research Designs & Standards Organization of Indian Railways’ the nominal dimensions of concrete block are as follows:

- Length: 400, 500 or 600 mm

- Height: 200 or 100 mm

- Width: 50, 75, 100, 150, 200, 250 or 300 mm

Classification of Concrete Blocks

As per ‘Indian Standard – IS 2185 (Part-1) 2005’ classification of concrete blocks is given as below

01. Hollow (Open and Closed Cavity) Concrete Block

The hollow (open and closed cavity) concrete blocks are defined in followings grades:

Grade A:

- Grade-A type of blocks is used as load-bearing units and have a minimum block density of 1500 kg/m3. Grade-A type of blocks are manufactured for minimum average compressive strengths of 3.5, 4.5, 5.5, 7.0, 8, 5, 10.0, 12.5 and 15.0N/mm2 at 28 days.

Grade B:

- Grade-B type of blocks is also used as load-bearing units and have a block density between 1100kg/m3 and 1500kg/m3. Grade-B type of blocks are manufactured for minimum average compressive strengths of 3.5 and 5.0N/mm2 at 28 days.

02. Solid Concrete Block

Grade C:

- The solid concrete blocks are used as load-bearing units and have a block density not less than 1800kg/m3. Grade-C type of blocks are manufactured for minimum average compressive strength of 4.0 and 5.0N/mm2.

Properties of Hollow Concrete Blocks

According to ‘Building Materials & Technology Promotion Council – Ministry of Housing & Urban Poverty Alleviation, Government of India’, physical properties of hollow concrete blocks are as below:

01. Moisture Movement: Not more than 0.09%

02. Water Absorption: Not more than 10%

03. Drying Shrinkage: Not more than 0.06%

04. Compressive Strength:

- For Grade A: 3.5 to 15.0 N/mm2

- For Grade B: 3.5 and 5.0 N/mm2

05. Density:

- For Grade A: 1500 kg/m3

- For Grade-B: 1100 kg/m3 to 1500 kg/m3

Uses of Hollow Concrete Blocks

Hollow concrete blocks are used in all type of masonry construction such as,

- Exterior load-bearing walls

- Interior load-bearing walls

- Curtain walls

- Partition wall and panel walls

- Backing from brick, stone, and other facing

- Fireproofing over a structural member

- Fire-safe walls around stairwells, elevators

- Piers, column and retaining walls etc.

- Boundary fences

Advantages of Hollow Concrete Block Masonry

According to the research by ‘Chaure, A. P., Shinde P. A. et al.’ followings are the advantages of hollow concrete blocks,

01. Hollow concrete block masonry is the easier and faster construction practice as compared to any other masonry practices.

02. Hollow concrete block masonry reduces the cost of construction labour and construction materials because the use of a larger size of concrete block reduces the number of joints in work.

03. Semi-skilled or unskilled labour can also work in this type of construction.

04. These concrete blocks need low maintenance and are durable.

05. They are eco-friendly materials as industrial wastes, such as fly ash or bottom ash are used as raw materials.

06. Reinforcing the hollow block masonry is possible as there is no additional formwork or any construction machinery required.

07. Hollow concrete block masonry is highly durable as the concrete is compacted by high pressure and vibration, which gives substantial strength to the block. Adequate curing increases the compressive strength of the blocks.

08. As the hollow concrete blocks are light in weight, they reduce the weight of the structure and hence light structural member or less percentage of steel is required for a given R.C.C building.

09. Presence of rough texture on concrete blocks provides good bonding between cement mortar and concrete blocks.

10. It is possible to construct a thin wall by using hollow blocks. Therefore, it helps to save space and increase the floor area or carpet area, i.e. carpet area efficiency is better.

11. In the hollow blocks, the voids or cores can be filled with steel bars and concrete for achieving high seismic resistance.

12. Hollow concrete blocks have good insulating properties against sound, heat and dampness.

13. These blocks have low water absorption than conventional bricks. If you want to know how to measure water absorption in bricks then read the water absorption test of bricks.

14. Hollow concrete block can safely resist the atmospheric action. This block doesn’t require protecting covering.

15. It has good fire resistance.

Disadvantages of Hollow Concrete Block

01. The cost of hollow concrete blocks is higher than the conventional bricks.

02. The house built with hollow blocks without any interior reinforcement is likely to suffer damage during earthquakes.

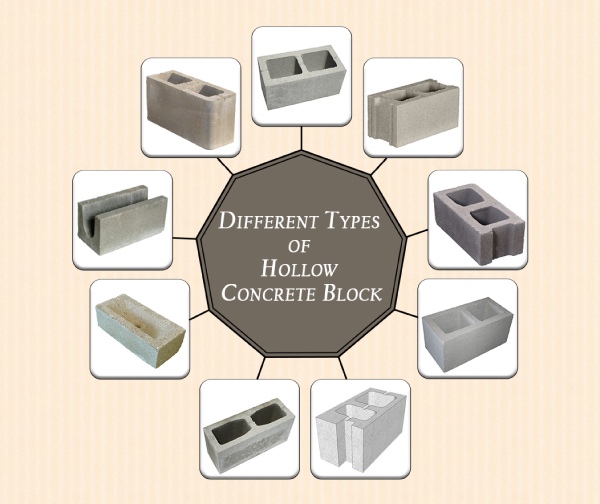

Different Types of Hollow Concrete Blocks

Hollow concrete blocks are available in different types according to their shape, needs and design such as,

01. Concrete Stretcher Blocks

02. Lintel Blocks

03. Partition Concrete Blocks

04. Concrete Pillar Blocks

05. Corner Concrete Blocks

06. Jamb Concrete Blocks

07. Bullnose Concrete Block

08. Frogged Brick Blocks

Let us discuss each one of these types in detail.

01. Concrete Stretcher Blocks

Concrete stretcher blocks are most commonly used hollow concrete blocks in construction. These blocks are used to join the corner of masonry units. Stretcher blocks are placed with their length parallel to the face of the wall.

02. Lintel Blocks

Lintel blocks are also called channeled blocks or beam blocks; they are a U-shaped concrete masonry unit. These blocks have a deep groove along the length of the block. After placing the blocks, these grooves are filled with concrete along with reinforcement. Lintel blocks are used for the provision of the beam or lintel beam. Lintel beam is generally provided on the top of the portion of doors and windows, which transfers the load coming from the top.

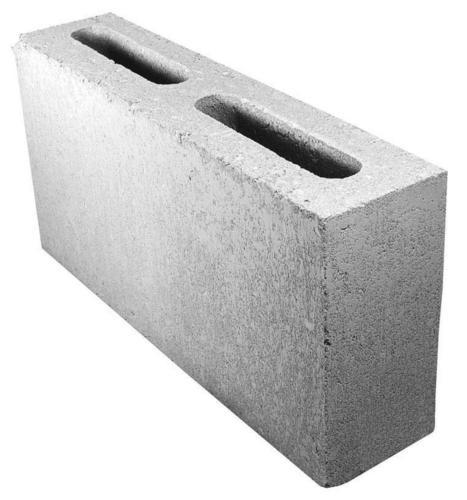

03. Partition Concrete Blocks

Partition concrete blocks are an ideal choice for the construction of partition walls. The hollow part of these blocks is divided into two or three components, and the height of the partition block is larger than its breadth.

04. Concrete Pillar Blocks

Concrete pillar blocks are also known as double corner block as both of its corners are plain. Thus, they are mostly used when two ends of the corner are visible. As the name suggests, , concrete pillar blocks are widely used in pillars or piers.

05. Concrete Corner Blocks

Concrete corner blocks are used at the corners of the masonry or at the end of window or at door opening. As shown in the image, one corner of the block is plain while the other is stretcher design. These blocks are arranged in such a manner that the plane end of block is exposed to the outside and another end is locked with the stretcher block.

06. Jamb Concrete Blocks

Jamb concrete blocks are used when there is an elaborated window opening in the wall. They are connected to stretcher and corner of the blocks. For the provision of double hung window, jamb concrete blocks are beneficial to provide space for the casing member of window.

07. Bullnose Concrete Blocks

Bullnose concrete blocks are similar to corner blocks in structure and function. But especially when we want rounded edges at the corner, these blocks are chosen.

08. Frogged Brick Blocks

Like the frogged brick, these frogged brick blocks having a frog on its top along with header and stretcher. This frog will help the blocks to hold mortar and develop a strong bond with the top lying block.

Summing up, hollow concrete blocks or hollow concrete masonry units are more beneficial building material than conventional bricks. They speed up the construction practice and reduces the overall construction time. The hollow blocks are also cheaper and are available in various sizes and shapes. With all these benefits, they are durable as well. Thus, they have become the preferred material for today’s buildings.

Also Read:

Types of Materials that Can be Used in Masonry and its Specifications!

Clay Bricks vs Hollow Clay Bricks: Choose the Right Construction Material

Comparison of Red Bricks vs AAC Blocks vs Fly Ash Bricks vs Solid Concrete Blocks vs CLC Blocks

Image Courtesy: Image 3, Image 5, Image 6 – builderup, Image 7, Image 8, Image 9, Image 11, Image 12