Concrete is a complex material of cement, sand, coarse aggregate, water and chemical admixtures (if required). Making of concrete is very easy, but the concrete produced by a mixer is required to be transported for the placement and which is very important. Proper transportation of concrete the most essential because it affects the quality of concrete. Concrete should be transported to the construction job site in a certain time before its initial setting time and its handling may also produce segregation and loss of slump if the distance is long or time is more.

Transportation of concrete mix is defined as the transferring of concrete from the mixing plant to the construction site. The main objective in transporting concrete is to ensure that the water-cement ratio, slump of concrete or consistency of concrete workability, air content, and homogeneity are not modified from their intended states and also prevent segregation and bleeding.

Importance of Transporting Concrete

Transportation of concrete must be well thought out and organized efficiently. Normally thirty minutes of transportation time is acceptable for small jobs. For a central or portable plant like a ready-mix plant, concrete should be discharged from agitating transporting equipment within two hours. If the non-agitating transporting equipment is used, this time is reduced to one hour. All delays must be avoided to prevent honeycombing or cold joints.

There are many factors that determine which type of transportation is most suitable for concreting and taken into consideration when choosing the mode of transportation of concrete such as,

- Type and constituents of the concrete mix,

- Weather conditions such as humidity, temperature, wind speed etc.,

- Size of construction,

- Type of construction,

- Topography,

- Location of the batching plant,

- Cost of transportation

If you choose the wrong mode of transportation, concrete might get segregated and useless. Therefore, it is most important that the adequate mode is selected for transportation of concrete as per requirements.

Methods for Transporting Concrete

After many years of development of the concrete technology, there are a wide variety of equipment from hand tools to heavy industrial machinery with methods (techniques)for transporting concrete.

Here we have mentioned various methods or equipment for transporting concrete according to its direction of transportation such as horizontal or vertical above the ground level and vertically below the ground level etc.

01. Mortar Pan

Mortar pan is used when the concrete is carried out in small quantities. In this method, the greater surface area of concrete is exposed to drying conditions and results in a great loss of water particularly in hot weather concreting. Remember that the mortar pan should be clean and wet at the starting of concrete transportation.

02. Wheelbarrow

The wheelbarrow is used for transporting concrete at ground level. It’s another normal way after mortar pan for transporting concrete ground level. If the transportation distance is long or ground is rough, wheelbarrows are provided with the pneumatic wheel to avoid segregation of concrete due to vibration.

03. Crane Bucket and Ropeway

A tower crane bucket and ropeway are the methods for transporting concrete above the ground level. Crane is used for transporting concrete horizontally as well as vertically and also in an inclined way so that it is also called two- or three-dimensional transport. It is a familiar way in medium and large sites in high rise construction projects. In this method transportation of concrete is fast and the placement of concrete takes place at the particular point. Crane consists of skips or buckets for containing concrete.

Ropeway buckets are more suitable for concrete work in the valley, dam site, pier in the river and over some obstruction etc. There are various types of crane available according to the site, height and radius of operation such as tower crane, crawler mounted, derrick crane, wheel mounted, a hydraulic crane etc.

04. Chute

A chute is adapted for transporting concrete from ground level to the lower level. It is used when the labour can’t reach the place of concrete due to the less space like trenches. The surface should have some slope not flatter than 1 vertical to 2.5 horizontal. Concrete may get slightly compact mass without any separation or segregation.

05. Skip and Hoist

Skip and hoist are adopted for transporting concrete vertically for high rise building construction. At a ground level, skip is directly fed by the mixer and at the discharging point, it discharges automatically or manually. Skip is a travel on the vertical rail for the transporting concrete.

06. Transit Mixer

Transit mixer is one of the most popular equipment for transporting concrete over a long distance mostly in RMC plant (Ready Mixed Concrete plant). Transit mixer is mounted on the truck and maybe having a capacity of 4 to 7 m3. Concrete is continuously agitated in the truck with 2 to 6 revolution per minute. A small pump is fitted on a truck mixer for discharge concrete. Concrete which fed in the mixer can be either dry or wet mix. If the mix is wet then it must reach the site in 1 or 1.5 hours.

07. Belt Conveyors

Belt conveyors are used for a small horizontal distance such as 5-meter to 10-meter. The initial cost of setting up of the belt conveyor is high. It can place large volumes of concrete quickly where access is limited. Concrete may get to segregate in steep inclines as the belt passes over the rollers. It is suggested that low slump concrete is used for slower moving belts and higher slump concrete by faster moving belts. If this method used in adverse weather conditions such as hot and windy, the long reaches of the belt must be covered. If there is any breakdown of machines, a large amount of concrete in the belt needs removal by other means and the belt is to be cleaned and washed.

08. Pumps and Pipelines

Pumping of concrete is universally accepted and more reliable method of concrete transportation and placing. Its working starts with the suction stroke which sucks the concrete inside the pipe. For the suction and delivery of concrete, a piston is provided.

It’s essential to choose the correct diameter and wall thickness of the pipeline to match the pump and requirements of placing rate. For long horizontal distance, high pumping pressure is required for that large diameter pipe would be an ideal choice to account for less resistance to flow. If you need to pump concrete to height, due to the gravity and the weight of concrete in the line, a smallest possible diameter of pipelines should be used.

How far concrete can be pumped, it is usually depending on the types of pump and the concrete mix design like slump or workability etc. If you select a high-pressure pump and also give special attention to concrete mix design than you would be able to pump concrete to a height (vertical) over 400 m and a horizontal distance of over 2000 m.

09. Tremie

Tremie is the most common method for underwater transportation of concrete, tremie pipe is used for that. This word “tremie” is derived after the French word hopper. A tremie pipe is a pipe having a diameter of about 20 cm capable of easy coupling for an increase or decrease of length. A funnel is fitted to the top end to facilitate pouring of concrete. The bottom end is closed with a plug or thick polyethene sheet or such other material and taken below the water and made to rest at the point where the concrete is going to be placed.

10. Dumpers and Trucks

Dumpers and trucks are the ordinary open steel tipping lorries used for long hauls in horizontal transport at ground level. It’s used for large concrete works. This method may also cause segregation because of the jolting during transit.

11. Monorail System

Monorail system consists of a track and a power wagon mounted on the single rail track, which can move at a speed of 80-90 meter/minute. This method is used in the construction of tunnels, dams and other such kinds of constructions. Segregation is likely to take place due to jolting of concrete in the wagon over each rail joint. Hence, wet mixes are generally not suitable for monorail system transport.Transporting concrete affects the quality of concrete and as specified above, the successful transportation of concrete requires the careful management of various factors. Once the appropriate transporting equipment and method are chosen and the important factors are addressed, concrete is ready to move on to the next critical step, known as placing.

Also Read:

Different Methods for Mixing Concrete

What is Compaction of Concrete?

Curing of Concrete: Things to Keep in Mind While Curing

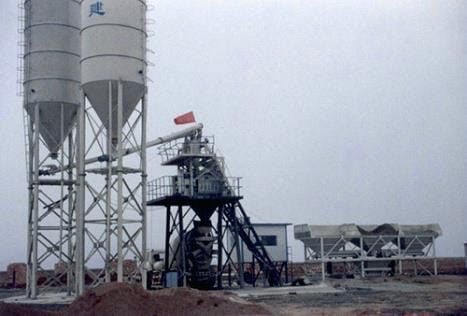

Image Courtesy: Image 5