Concrete is a vital construction material which is a significant parameter for structural strength. By its name, we start assuming that concrete has to be impervious, leak proof, damp proof and capable enough to withstand the load. If concrete is non water it will cause corrosion in steel in RCC structures and therefore it has to be impervious. Hence the name pervious concrete itself misleading and confusing. Then why and how the pervious concrete should be used?

Here we are discussing pervious concrete. Concrete and that too pervious, yes, at its first sight it sounds unacceptable and illogical. But it is one major environment – friendly material used by the concrete industry as GREEN industry practice for addressing pollution control, stormwater management and sustainable design. The increased interest in pervious concrete is due to its benefits in stormwater management and sustainable development.

What is Pervious Concrete?

The pervious concrete is a special type of concrete, which consists of cement, coarse aggregates, water and if required, admixtures and other cementitious materials. (like silica fume, fly ash etc.) In this type of concrete, there are no fine aggregates normally used in the concrete matrix. Hence the void content is more which allows the water to flow through its body. Therefore, the pervious concrete is also called as Permeable concrete or Porous concrete.

While using porous concrete, the open cell structures allow stormwater to filter through the pavement and into the underlying soils. In other words, this concrete helps in protecting the surface of the pavement on which it rests and its environment. The Porous concrete is made up of the same materials as conventional concrete. 15 -30% of its volume consists of interconnected void network, which allows water to pass through the concrete. Pervious concrete has the capacity to allow the passage of 11.35-18.97 litres of water per minute through its open cells for each square foot (0.0929 m2) of surface area which is far greater than most rain occurrences.

General Properties of Pervious Concrete

- The permeable concrete mixture is very stiff as compared to traditional concrete.

- Slumps are generally less than 20 mm, although slumps as high as 50 mm have been used.

- The normal range of densities and void contents are of the order of 1600 kg/m3 to 2000 kg/m3 and 20 to 25%

- The permeable concrete infiltration rate (permeability) varies with aggregate size and density of the mixture but will fall into the range of 80 to 720 litres per minute per square meter.

- The typical permeability concrete pavement system has a permeability of 143 litres per minute per square meter.

- In contrast, the steady-state infiltration rate of soil ranges from 25 mm/hr to 0.25 mm/hr.

- The strength and permeability of concrete are function of the concrete density. Higher strength can be achieved with greater amount of consolidation but results in lower the permeability.

- Flexural strength of porous concrete generally ranges between about 1 MPa to 3.8 MPa.

- The relationship between the w/c ratio and compressive strength of conventional concrete is significant. A high w/c can result in the paste flowing from the aggregate and filling the void structure. A low w/c can result in reduced adhesion between aggregate particles and can result in placement problems.

Also Read:

Flexural Strength Test to Check Tension in Concrete

Cube Test to Check the Compressive Strength of Concrete

Pervious Concrete

Problems with the Permeable Concrete

01. Clogging:

- It might be possible that pervious concrete can get severely clogged due to possibly poor maintenance. However, it is unlikely that the permeability of porous concrete will get affected.

02. Abrasion and Ravelling:

- Abrasion and ravelling could be a problem. Good curing practices and appropriate w/c ratio (not too low) is important to reduce ravelling. Some loose stones on a finished pavement are always expected, but severe ravelling is unacceptable. Use of snow ploughs can increase ravelling.

03. Freeze and Thaw:

- If the pervious concrete is exposed to very low temperature, there is a significant risk that the concrete would undergo extensive freeze-thaw cycles if the placement were fully saturated.

- The following measures can improve the permeable concrete freeze-thaw resistance:

(a) It can be enhanced by the use of fine aggregates to increase strength and slightly reduce voids content to about 20%.

(b) By use of air-entrainment of the paste with the use of air entraining admixtures.

(c) By use of a perforated PVC pipe in the aggregate base to capture all the water and let it drain away below the pavement.

Benefits of Pervious Concrete

Benefits of Pervious Concrete are as follows:

- Enables recharge of underground aquifers

- By allowing rainwater to percolate into the ground, it prevents ponding and flooding problems.

- Prevents storm water runoff from flowing off the site, thus protecting downstream natural water bodies

- Helps purify storm water by filtering out contaminants, such as sediment, bacteria, and chemicals

- It may help in reducing the Heat Island Effect often associated with large impervious areas.

- Reduces the need for expensive storm water management practices, such as retention pond, particularly in an urban area where land is scarce and prohibitively costly.

Major Applications of Pervious Concrete

- Low-volume pavements

- Residential roads, alleys, and driveways

- Sidewalks and pathways

- Parking areas

- Low water crossings

- Tennis courts

- Sub-base for conventional concrete pavements

- Slope stabilization

- Well linings

- Hydraulic structures (where permeability is accepted)

- Swimming pool decks

- Pavement edge drains and Tree grates in sidewalks

- Groins and seawalls

- Noise barriers

Pervious Concrete – Parking Area

Porous Concrete – Swimming Pool Deck

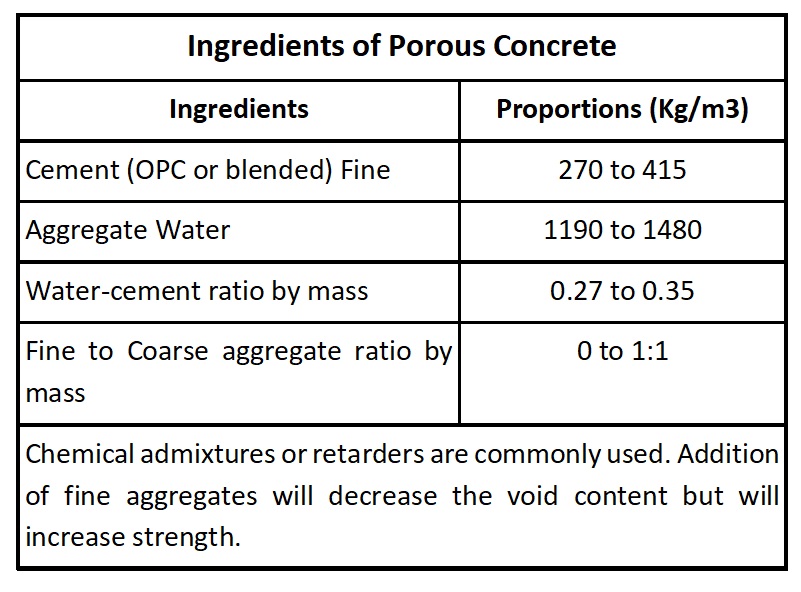

Pervious Concrete Mix Design

Permeable concrete is cast from the same material as conventional concrete, except that there are no or little fine aggregates. The coarse aggregate size of 3/ inch is used to minimize surface roughness and for better aesthetics. However, sizes can vary from ¼ inch to ½ inch. W/C ratio should be within 0.27 to 0.34. In the manufacturing of water permeable concrete ordinary Portland cement and blended cement can be used. Chemical admixtures like water reducing admixture or concrete retarder can also be used in porous concrete.

Problem Faced in Manufacturing of Permeable Concrete

- It requires long mixing time in the batching plants (about 20 min)

- It gives Poor workability of concrete, very dry mix, hence difficult for placing of concrete.

- In water permeable concrete too, the amount of water used in the mix is as important as standard concrete

- Addition of too much water results in segregation of concrete. (usually higher than standard concrete)

- With the use of less water, concrete is difficult to mix and there is a possibility of balling of the mix.

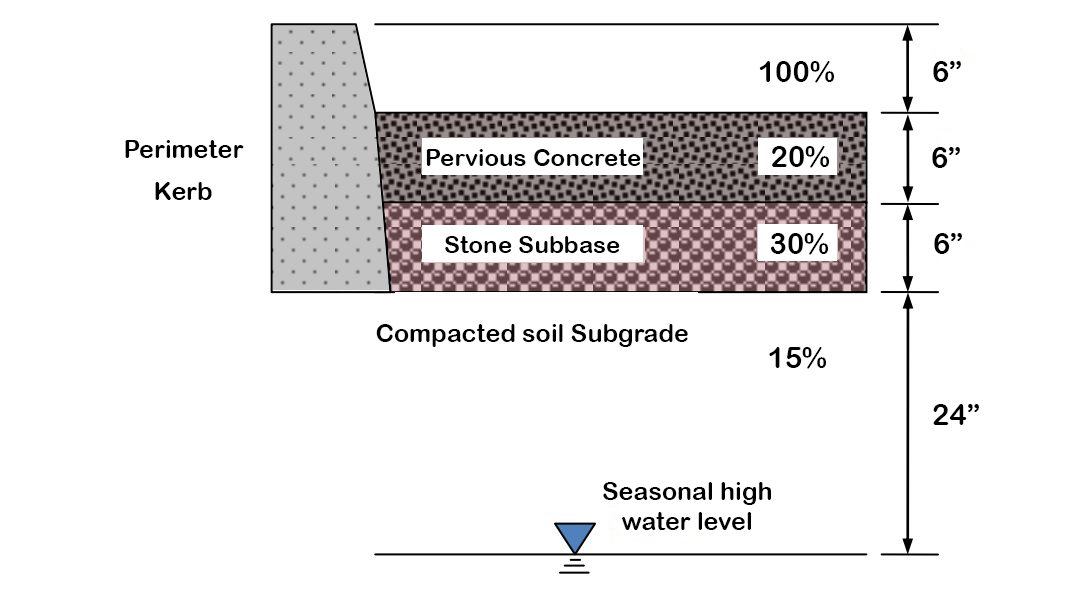

Design Pervious Concrete to Stormwater Management

Typical cross section of permeable concrete used for the stormwater drain is given in figure:

Cross Section of Permeable Concrete Pavement

- Kerb area: It is provided to retain flood water, usually 6” layer (100% voids)

- Pervious concrete: It is provided generally in 6” layer (20% voids)

- Base or subbase: It is made of compacted metal (stone), usually 6” layer (30% voids)

- Subgrade: It is made of compacted existing soil, usually 24” (15% void)

Stormwater Storage Capacity (without Storage Volume of Sub-Base Soil)

= Voids in Side Kerb + Voids in a layer of Pervious Concrete + voids in a layer of the stone layer

= (6 inch × 100% voids) + (6 inch × 20% voids) + (6 inch × 40 % voids)

= 9.6 inch (244mm)

Considering the Storage Volume of Sub-Base as Well

= Voids in Side Kerb + Voids in a layer Pervious Concrete + voids in a layer of stone layer + Voids in a layer of sub base

= (6 inch × 100% voids) + (6 inch × 20% voids) + (40% × 6 inch) + (24 inch × 15 %)

= 13.2 inch (335mm)Pervious concrete pavements are environmentally friendly and offer a very cost-effective solution for sustainable construction. Its ability to capture storm water and recharge groundwater while reducing storm water runoff enables porous concrete to play a significant role. This type of concrete is a smart sustainable option with very high potential. Permeable concrete is an ideal solution to manage storm water, re-charging of groundwater, flood control at down streams and for sustainable land management.

Also Read:

Self-Compacting Concrete | High Performance Concrete

What is a Precast Concrete?

Basics of Fibre Reinforced Concrete

Transparent Concrete: Modern Aesthetic Future for your Home!

Image Courtesy: Image 1 – abettercity

Author Bio

Bhushan Mahajan