Concrete is a commonly used construction material, which is the mixture of cement, sand, aggregate, and admixtures blended with water. Concrete gets hardened with time and gains the strength, and for the best results in a construction of your dream home, mixing of concrete is said to be the most important process. All the ingredients are to be mixed in proper proportion because the properties of concrete like workability, strength, surface finish, and durability of concrete etc. are ensured by the right and proportionate blending.

Normally two methods are used for proportioning different ingredients, i.e. nominal mix and design mix of concrete. Selection of types of concrete mix depends on the requirement of strength and nature of work.

Nominal Mix

In the nominal mix concrete, all the ingredients and their proportions are prescribed in the standard specifications. These proportions are specified in the ratio of cement to aggregates for certain strength achievement.

The mix proportions like 1:1.5:3, 1:2:4, 1:3:6 etc. are adopted in nominal mix of concrete without any scientific base, only on the basis on past empirical studies. Thus, it is adopted for ordinary concrete or you can say, the nominal mix is preferred for simpler, relatively unimportant and small concrete works.

Nominal Mix of Concrete

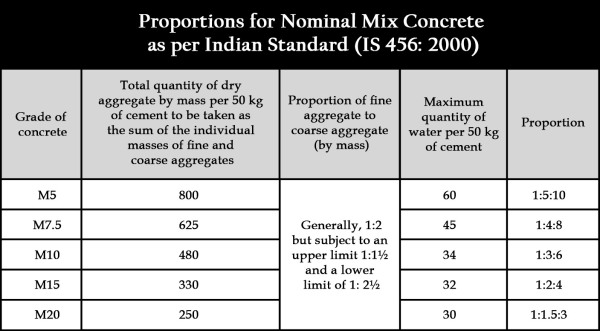

As per the ‘Indian Standard- IS 456:2000’, nominal mix concrete may be used for concrete of M20 grade or lower grade such as M5, M7.5, M10, M15.

What Do You Mean by M20?

M 20 is identified as the concrete grade in which, M denotes the Mix and 20 denotes the compressive strength of concrete cube after 28 days of curing in N/mm2. There are various grades of concrete that can be used like M10, M15, M20, M25, M30, etc.

Proportions for Nominal Mix as Per Indian Standard

The proportions of materials for nominal mix lower than M20 grade concrete shall be in accordance with IS 456: 2000, which are shown below:

NOTE:

In the above table, the proportion of the fine to coarse aggregates should be adjusted from the upper limit to lower limit progressively as the grading of fine aggregates becomes finer, and the maximum size of the coarse aggregate becomes larger, graded coarse aggregate shall be used. I.e. for an average grading of fine aggregate (that is Zone II- IS 383- Table 4). The proportions are generally 1:1½, 1:2, and 1: 2½ for the maximum size of an aggregate 10mm, 20 mm and 40 mm, respectively.

As per the IS 456: 2000, in the nominal mix can be proportions changed if the quantity of water is to be increased to overcome the difficulties of placement and compaction of concrete so that the water-cement ratio can be maintained as specified.

Nominal mix generally contains volumetric batching. Normally the proportion is decided by the weight, and for concreting it is converted to volumetric proportion, i.e. in respect to 1 bag of cement, i.e. 50 kg of cement standard measurement boxes are made on site, which is in the proportion of 1 bag of cement. These measurement boxes called box gauges.

Advantages of Nominal Mix Concrete

01. The nominal mix is the prescriptive type concrete because a proportion is pre-decided.

02. It is easy to make at the construction site.

03. It doesn’t take much time to decide the proportion because proportions are already given by standard code.

04. No need to get skilled persons for making the nominal mix concrete.

Disadvantages of Nominal Mix Concrete

01. The major drawback of nominal mix is, it’s based on the experience and past empirical studies, and it lacks a proven scientific approach.

02. It may or may not create exactly designed strength unless all the other factors like compaction, w/c ratio, curing of concrete are strictly followed.

03. The water-cement ratio is considered by assumption so, if we don’t take care of it, sometimes it leads to bleeding and segregation of concrete resulting in poor strength and accordingly it hampers the durability of concrete.

04. There is no consideration for properties of aggregates such as grading and density of aggregate etc.

05. In the nominal mix, sometimes cement content is used higher than the requirement, which increases the overall cost of the construction.

06. No laboratory tests are conducted to ensure the quality of fresh concrete.

07. This mix does not consider and check specific properties of individual ingredients. For example, if we take cement as an element, the fineness of cement, the grade of cement and type of cement, size and grading of aggregate etc. are generally not counted individually while making this nominal mix concrete.

Design Mix

In design mix concrete, proportions of the ingredients are properly determined with their relative ratio to achieve the concrete of desired strength. Not only the desired strength but also according to the properties of fresh concrete like workability or performance of concrete with the certain specifications are taken in detail consideration.

All the materials are tested before the use and the entire process is found based on trial and error of various options from available materials designated for the work.

Design Mix of Concrete

Guidelines for Mix Design

There are various standard guidelines available for making a design mix concrete such as,

01. IS Method – Concrete mix proportioning guidelines (Bureau of Indian Standards – I.S. 10262- 2009) and Recommended Guidelines for Concrete Mix Design- I.S. 10262- 1982,

02. BS Method – (British Standard – BS EN 206- 1 and its complementary standards BS 8500 parts 1& 2)

03. ACI Method – (American Standard – ACI 211, 211- 91, reapproved- 2002).

Mix design is the most intellectual and rational approach for the selection of specific materials with their proportion and more or less for the unique characteristics. Design mix contains weight batching. It not only makes concrete of desired strength but also it is cost efficient.

Requirement of Materials Properties for Mix Design

In the design mix method, you have to check every property of the blended materials and after that, you can start design construction. Followings are the properties of ingredients which you have to check,

01. Cement:

- Grade of the Cement,

- Consistency of the Cement

- Initial Setting Time and Final Setting Time of the Cement

- Specific Gravity of the Cement

02. Aggregate:

- Density of the Aggregates

- Bulking of the Fine Aggregate

- The Specific Gravity of the Fine Aggregate and the Coarse Aggregate

- Grading of the Aggregate

- Fineness Modulus

- Particle Size

- Silt Content

- Specific Gravity and Water Absorption

- Unit Weight etc.

Advantages of Mix Design Concrete

01. Design mix is more scientific than the nominal mix.

02. Mix design is widely used for more extensive and important concrete works.

03. Mix design is based on the actual available material to be used in construction work.

04. If the locally available material can satisfy the standard criteria, it can be used for making mix design concrete so that the mix can reduce the cost of importing material from outside.

05. The quantity of the ingredient to be used are rational, i.e. it’s neither overused nor underused.

06. It is based on the laboratory trial/error experiment method.

07. It gives an assurance of strength.

08. Mix design concrete is performance-based concrete.

09. The designer can use admixtures rationally to modify the properties of concrete according to their requirement.

10. Slump and strength can be related, i.e. for strength. We can use different slump by changing water/cement ratio with or without the use of admixtures so that it suits the concreting of different elements, i.e. for footing it may have less slump, i.e. less water-cement ratio, but for thin elements like chhajja or thin walls, it may need a larger slump, i.e. higher w/c ratio or more quantity of admixture. This is not possible in the use of the nominal mix.

Disadvantages of Mix Design Concrete

01. Mix Design is more time consuming.

02. If the type or quality of desired ingredient gets changed during the progress of work, all the proportion will get changed of mix design concrete. Strict supervision is required as it is important or we may end up making a fresh design which may delay the entire project.

03. It is always better to have mix design with 2/3 possible brands of cement and also to have aggregate from different sources.

04. Need the involvement of the skilled persons to prepare the mix design.

In the final note, both nominal mix and design mix of concrete are the important criteria for proportioning different ingredients of concrete. A design mix concrete is preferred over a nominal mix concrete especially where the concrete is above M20 grade and also where the requirement is of the different workability and risk of deviation. It is used in the large projects to get asserted of the assurance of strength, durability and workability.

Also Read:

Foamed Cellular Light Weight Concrete | Applications & Advantages

Pervious Concrete – A Sustainable Choice in Construction

Green Concrete: Its Application, Advantages & Disadvantages

Polymer Concrete: Its Pros-Cons, Uses & Properties