As everyone knows cement, sand, and aggregates are the main components of concrete. Out of all three, aggregate works as a structural filler in the concrete mix. But its role is far more important and essential than that inferred in a simple statement. Coarse aggregate occupies 70% to 80% of the volume of concrete. Aggregates are the material that the cement paste coats and binds together.

The quality of aggregates imposes a significant impact on the properties of concrete like workability, strength, weight, durability etc. So, it is necessary to know all the properties of aggregates such as its shape, size, specific gravity, water absorption, flakiness, surface texture, abrasion, and skid resistance etc. before using aggregates for any project.

In this article, we have discussed the specific gravity of coarse aggregates in terms of specific gravity definition, its importance, and the standard guidelines to measure it including water absorption test for coarse aggregates etc.

What is Specific Gravity?

According to the ‘Oxford Dictionary of Construction, Surveying, & Civil Engineering’, specific gravity is also known as relative density. It is the ratio of a material’s density to the density of another material. However, the ratio almost always uses water as the standard comparison. The density of water is 1000 kg/m3. Density of all other materials is divided by that of water to calculate the relative density.

Or in simple words, it is the ratio of the mass of a volume of a solid material in the air to the mass of the same volume of distilled water at a stated temperature. Specific gravity is also known as bulk specific gravity.

Also Read: Classification of Aggregates According to Nature of Formation

Specific Gravity of Coarse Aggregates

As per the definition given in the ‘IS: 2386 (Part III) – 1963’, (Indian Standard- Methods of Test for Aggregates for Concrete – Specific Gravity, Density, Voids, Absorption and Bulking), the specific gravity of coarse aggregates is the weight of the aggregates dried to constant weight in an oven at 100°C divided by its absolute volume including the natural voids within the aggregate particles.

All rocks or stones contain some small amount of voids, and the specific gravity is an indirect measure of aggregates porosity. A low specific gravity may indicate high porosity, and therefore, it offers poor durability and low strength.

In the aggregates, some of the pores are permeable, whereas others are impermeable. Therefore, two types of specific gravities are defined: one is the absolute specific gravity, and second is the apparent specific gravity. In the determination of true or absolute specific gravity, both the permeable and impermeable voids are excluded. But it is not of much practical use as the volume of impermeable internal pores is too difficult to determine.

On the other side, for the determination of the apparent specific gravity, the volume of impermeable internal pore is added to the effective volume of the aggregates. It does not include the permeable pores. The specific gravity will first depend upon the basic chemistry of rock and then on the amount of pores or voids within it. If the basic rock is weak, then nothing will help you.

As per definition in ‘IS: 2386 (Part III) – 1963’, (Indian Standard- Methods of Test for Aggregates for Concrete – Specific Gravity, Density, Voids, Absorption, and Bulking),

Apparent Specific Gravity of Aggregates: It is calculated by measuring the weight of the oven-dry aggregate divided by its absolute volume excluding the natural voids in the aggregate particles. It is the realistic quantified data validated to use for the calculation of concrete mix proportioning.

Importance of Specific Gravity of Aggregates

Specify gravity is important for followings numerous reasons:01. The specific gravity of aggregates indirectly measures its density; hence it is the most essential parameter of strength or quality of the aggregates. Higher the specific gravity, higher is the strength. It is due to higher specific gravity there would be higher compressive strength of aggregates and hence it passes on to the concrete.

02. Lower specific gravity indicates high porosity. Such aggregates are weaker in comparison to the aggregates of higher specific gravity.

03. It is of important consideration when you deal with light weight aggregates.

04. Some harmful particles are lighter than the good particles in aggregates. Hence, by tracking the specific gravity of aggregates, one can get to know the change of material or possible contamination in it.

05. During the production of aggregates by using the difference in specific gravity, harmful particles can be separated from the goods by using a heavy media liquid.

06. In the cement concrete, the percentage of voids and the solid volume of aggregates can be calculated with the help of its specific gravity.

07. In the concrete technology, specific gravity of aggregates is essential in calculation of compacting factor in connection with the workability measurements.

08. Looking to the above importance, one has to be reasonably cautious while using light weight aggregates and its impact on compressive strength of concrete has to be counted in detail.

Trade Groups of Rocks Used as Concrete Aggregate

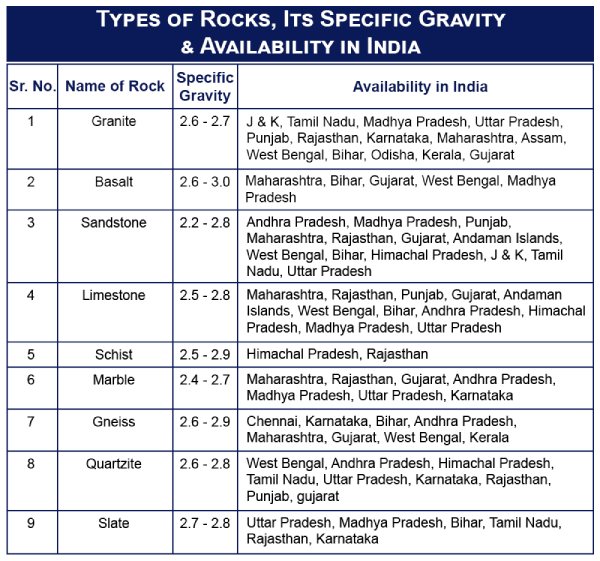

According to ‘IS: 383 – 1970’ (Specification for Coarse and Fine Aggregates from Natural Sources for Concrete), granite, basalt, sandstone, limestone, schist, granulite, gneiss, marble, gabbro, dolerite, rhyolite are popular rocks used for obtaining aggregates.

Below mentioned are some types of rocks and their specific gravity as well as their individual availability in India.

Standard Guidelines for Testing Specific Gravity of Aggregates

- ASTM C127 – 15: Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregates

- AASHTO T 85: Standard Method of Test for Specific Gravity and Absorption of Coarse Aggregates

- IS: 2386 (Part III) – 1963: Methods of Test for Aggregates for Concrete – Specific Gravity, Density, Voids, Absorption and Bulking

Specific Gravity and Water Absorption Test of Coarse Aggregates

According to ‘IS: 2386 (Part III) – 1963’, (Indian Standard- Methods of Test for Aggregates for Concrete – Specific Gravity, Density, Voids, Absorption and Bulking), there are three main methods, used for measuring or finding the specific gravity of aggregates as per the size of aggregates.

- Method I – Aggregates larger than 10 mm

- Method II – Aggregates between 40 mm and 10 mm

- Method III – Aggregates smaller than 10 mm

For the aggregates between 40 mm and 10 mm, both Method I & II can be used. Here, we will see the test apparatus, procedure, calculations, and result recommendation of the specific gravity and water absorption of the aggregates as per the Method I in detail.

This test covers the procedures for determining the specific gravity as well as apparent specific gravity and water absorption of aggregates.

Water Absorption of Aggregates: Water absorption of aggregates is the percentage of water absorbed by an air-dried aggregate when immersed in water at 27°C for a period of 24 hours. It is an essential parameter of porosity. It is considered as a measure of resistance to frost action and sustaining weathering action. The water absorption of aggregates is also important in determining the net water-cement ratio in the concrete mix.

Test Apparatus

Followings apparatus are used to conduct the specific gravity test and water absorption test of aggregates:

01. Balance: A balance or scale of about 3 kg capacity to weigh accurately up to 0.5 g, and of such a type and shape, so as to permit within the basket containing the aggregates when suspended in water.

Apparatus for Specific Gravity and Water Absorption Test of Coarse Aggregate

02. Oven: A well-ventilated oven, which can be controlled thermostatically and it maintains a temperature of 100 to 110 ˚C.

03. Wire Basket (Density Basket): A wire basket or density basket of not more than 6.3 mm mesh or a perforated container of convenient size with wire hangers for suspending it from the balance.

Density Basket for Aggregates

04. Watertight Container: A stout watertight container in which the basket can be freely suspended.

05. Dry Clothes: Two dry, soft, and good quality absorbent clothes of size 75 x 45 cm.

06. Shallow Tray: A shallow tray of the area not less than 650 cm2.

Test Procedure

- Take a sample of 2 kg of aggregates. Wash the sample thoroughly to remove finer particles and dust from it.

- After washing, place aggregates in the wire basket and immerse it in distilled water at a temperature between 22°C and 32°C with a cover of at least 5 cm of water above the top of the basket.

- Immediately, after immersion, remove the entrapped air from the sample by lifting the basket containing aggregates 25 mm above from the base of the tank and allow it to drop again. Continue this process at least 25 times at the rate of about one drop per second. The basket and aggregates shall remain completely immersed during this process as well as for a period of 24 ± ½ hours afterwards.

- Then the basket and the sample are jolted and weighed in the water at a temperature of 22 to 32°C. If it is necessary for them to be transferred to a different tank for weighing, they are jolted 25 times as described above in the new tank before weighing. Note down this weight of aggregates and basket in water as A1.

- After that, remove the basket and the aggregates from the water and allow to drain for a few minutes. After that, empty the aggregates from the basket on the dry clothes and return the empty basket to the water, jolt it 25 times and weigh in water. Note down the weight of basket suspended in water as A2.

- Gently dry those aggregates with the dry cloth. Transfer aggregates to the second dry cloth if the first one cannot remove optimum moisture residue from them. After that spread out them in one layer for at least 10 minutes for surface to get dry completely and avoid direct sunlight on them. Then take the weight of these dry aggregates, which are saturated and note it as B.

- Next, place the aggregates in the oven on the shallow tray at a temperature of 100 to 110°C and maintain this temperature for next 24 ± 1/2 hours. Then remove aggregates from the oven and cool in an airtight container. After that, measure the weight of the aggregates and note down this weight of oven-dry aggregates as C.

Calculation

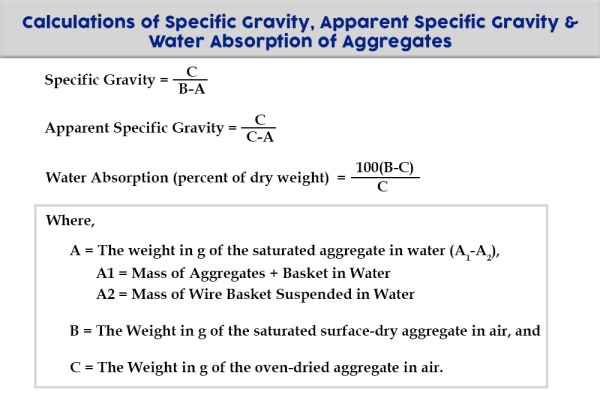

Calculations of specific gravity, apparent specific gravity, and water absorption of aggregates are as follows:

Recommended Results of Specific gravity and Water Absorption of Aggregates

The specific gravity of aggregates normally ranges from about 2.5 to 3.0. According to ‘A. M. Neville’ (Author of the Properties of Concrete), the majority of natural aggregates have a specific gravity of between 2.6 and 2.7. However high specific gravity is considered as an indication of high strength. Water absorption, ideally, shouldn’t be more than 0.6%.

Summing up, the specific gravity of coarse aggregates is indicative of its basic and fundamental quality. The specific gravity and porosity of aggregates greatly influence the strength and the water absorption capacity in concrete. A low specific gravity may indicate high porosity which often results in poor durability and the low strength of aggregates. Remember the concrete density and hence its strength significantly depends on the specific gravity.

Also Read:

Los Angeles Abrasion Test on Aggregate

Image Courtesy: Image 1(a) – emanumaq.weebly, Image 1(b), Image 4