Plastic shrinkage cracking occurs when fresh concrete is subjected to a very rapid loss of moisture during its plastic state. Plastic shrinkage cracks are caused by a combination of factors such as air and concrete temperature, relative humidity, and wind velocity at the surface of the concrete. These factors can cause high rates of evaporation in either hot or cold weather.

Size & Shapes of Plastic Shrinkage Cracks:

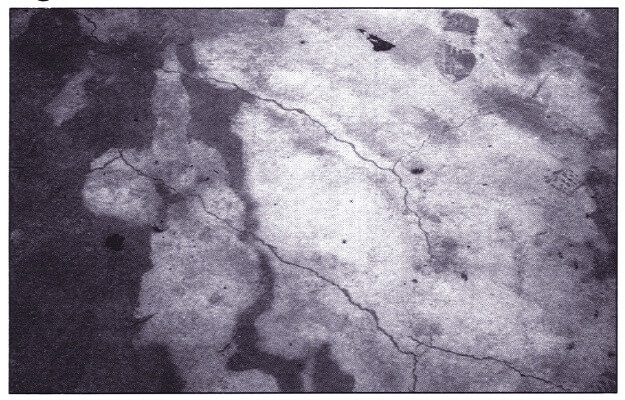

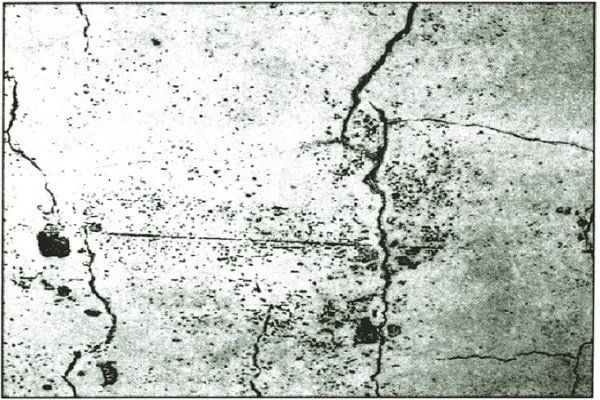

Plastic shrinkage cracks are generally parallel to each other and are spaced between 0.3 m to 2 m apart, up to 25 to 50 mm in depth or even pass through the entire slabs with thickness varying between 1 mm to 2 mm. The plastic shrinkage cracks also form a random pattern or a ‘map’ pattern.

Related: Classification of Cracks: Nature Wise, Width Wise & Shape Wise

Courtesy - Gujarat Ambuja Cements Ltd.

Note:

Plastic shrinkage cracking should not be confused with ordinary drying shrinkage cracks which occur only after a considerable time. Plastic shrinkage cracks are visible within the first 3 hours of casting although they are often not noticed until the following day.

Causes of Plastic Shrinkage Cracking:

- Water loss due to absorption by sub grade, formwork or aggregates

- Bleeding and sedimentation

- Poor workmanship and negligence

- Defects & errors in construction practices

- Movement of concrete arising from physical properties

- Deficiencies in design

- Weathering actions

- Alkali-Aggregate reactions

The above factors can singly or collectively cause cracking of concrete.

Summary of Plastic Shrinkage Cracks in Concrete:

01. Time of Appearance

- 30 to 180 minutes

02. Types/Locations

- Usually, occurs when change in thickness of slabs arises

- Diagonal cracks on Slabs roads & also occurs on roads

- Usually, occurs in Random pattern on reinforced concrete slabs

- Along & on top of reinforcement in reinforced concrete slabs

03. Primary Causes

- Rapid Early Drying Conditions

(a) If temperature is more than 36 0C, then water can evaporate very quickly

(b) Low Humidity can evaporate water very quickly.

(c) High Wind

- Reinforcement near the top surface ( minimum cover is not provided)

04. Secondary Causes

- Low rate of bleeding

05. Prevent Measures

- Improve early curing

- Use cohesive mix

- Avoid using gap graded materials

Remedies for Plastic Shrinkage Cracks:

Plastic shrinkage cracks usually appear in slab just after casting. However, these types of cracks are not harmful. It can be harmful in the long term as it might allow water to pass through cracks. Consequently, hide these types of cracks by spreading cement slurry on the slab.

Must Read:

Types & Summary of Cracks in Reinforced Concrete Column

Types & Summary of Cracks in Reinforced Concrete Beam

How to Inspect Cracked Concrete which Needs Repair?

How to Repair Concrete Cracks in RCC Structure or House?