Every year the construction industry witnesses the demand for new building materials. Researchers and experts are relentlessly looking for new materials to overcome the problems faced due to traditional building materials. Among the building materials, plywood has become one of the most eye-catching materials that have brought a huge difference in the wood industry. Nowadays, due to the beneficial properties of plywood, it has become the most demanding building materials over traditional materials like natural wood, bricks, plastic, etc. Plywood is a wonderful combination of lightness, strength and flexibility. Therefore, the growth of the plywood market is increasing day by day across the world.

What is Plywood?

Plywood is an engineered wood which is made by stacking several layers of wood veneers (thin slice of natural wood).

In comparison to wood, the plywood is easily and readily available in all regions. Due to the dearth and cost factor of wood, plywood has made a way to the construction industry in the last couple of decades. The application of plywood in a building and construction industry along with interior design had made it a popular building material all over the world.

Since the benefits of plywood are immense, many companies over the world have started the production of soft, hard, tropical and decorative plywood. We use various types of plywood for different uses. Right from making furniture to constructing a house including structural framework, manufacturing of doors, windows, drywall/partition wall, décor items, etc. plywood is used. Many other composite sheets or panels are available in the market, but still, expert or woodworkers prefer plywood due to its inherent properties like strength and stability, ease of working, cost, etc.

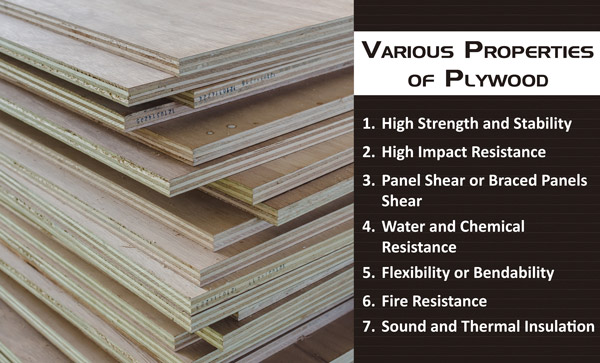

Properties of Plywood

01. High Strength and Dimensional Stability

Plywood derives its structural strength from the timber from which it is manufactured. This is in addition to the plywood properties obtained due to its laminated construction. Cross-graining (thin plies glued at the right angle with each other based on their pattern of grain) allows the plywood sheets to resist splitting and provides uniform strength with increased stability. Unlike natural wood, good quality plywood does not suffer from a change in size due to change in moisture content or humidity, i.e. it does not expand or contract. This is the biggest advantage of plywood.

Uses:

It is cost-effective when used in structural applications such as flooring, walls, partitions, formwork, cupboard, shelves, etc. because of its high strength and stability.

02. High Impact Resistance

Plywood has high tensile strength due to the cross lamination of panels which distributes the force over a large area and reduces tensile stress. Therefore, it can withstand overloading up to twice its designated load.

Uses:

- This is useful when we use it for flooring or concrete formwork.

- It is appropriate for the floor of various buildings, including industry with heavy wear.

03. Panel Shear or Braced Panels Shear

As stated by Bekhta, et al. in their research paper named “The effect of chemical treatment of wood veneer surfaces on their bond ability”; the plywood panels made by using treated veneers have higher shear strength than those made by using non-treated veneers.

Upon the treatment of veneer, plywood’s shear strength becomes nearly twice that of the solid wood when used in the wooden structure as bracing for resisting the lateral load.

Uses:

- This property makes it suitable for using as gussets in portal frames and as bracing panels and webs of fabricated beams of the wooden structure.

04. Water and Chemical Resistance

While manufacturing thin plies, veneers are treated with a substance that makes plywood highly resistant to water and chemicals. However, it has low water and chemical resistance capacity as compared to natural wood.

Uses:

- Since it is resistant to water and chemicals, it is therefore highly preferred in the chemical industries.

- To resist water and chemicals, the plywood is treated with waterproof glue along with the other chemical compounds. This is known as Marine plywood.

- This property makes it an ideal material mainly for furniture, concrete formwork and for outdoor projects garden furniture such as tables, chairs, and benches, decking, porches, arbours, pergolas, planters, etc. However, it may be noted that all plywood are not water resistant. One has to use an appropriate grade.

05. Flexibility or Bendability

Flexibility or the bending ability distinguishes plywood from the natural wood. Some special types of plywood can be easily bent without breaking or being damaged. As compared to wood; plywood can be manufactured to fit every requirement. Furthermore, the plywood thickness varies from a few millimetres to inches. The number of veneers used also ranges from three to several, thereby increasing the thickness of the plywood sheet. The extra layers of veneer add more strength to plywood. Lesser number of veneers or specially treated veneers makes plywood flexible or more bendable.

Uses:

- Flexibility in the shape and size of plywood makes it an appropriate material with respect to wood. Such flexible plywood is especially useful for creating furniture that is expected to have curved surfaces.

- Flexibility in thickness enables it for ceilings and panelling work, curved formwork, etc.

- It can also be used for manufacturing furniture, decorative items, etc.

06. Fire Resistance

Plywood can be treated with a fire-resistant chemical coating. It is combined with non-combustible materials such as fibrous cement or plasterboard. This chemical coating resists the oxidation process, thereby reducing the spread of fire.

Uses:

- This property makes it suitable for use in fire-resistant structures.

07. Sound and Thermal Insulation

As per research paper ‘Wood Adhesives and Bonding Theory’ published by Onur Ülker of Kirikkale University, the use of urea formaldehyde resin adhesives during the manufacturing of plywood enhance the thermal properties of plywood.

At the time of manufacturing of plywood, veneers or thin plies are glued together with resin adhesives, which make it a good thermal and noise insulator. The process of insulation of plywood significantly reduces heating and cooling costs.

Uses:

- In western countries, due to the need of high heat resistance, insulated plywood is highly preferable for ceilings, flooring, roofing, and wall cladding work.

Benefits of Using Plywood Over Other Natural Woods

- When you work with natural wood, the width of the wooden member is the biggest challenge, as it cannot be larger than the trunk of the tree. Hence whenever you want a wooden member of a large width either for door or partition, you have to provide joints. The joints need very skilled workmanship, so that thin lines are not visible and also, they perform well due to temperature and humidity change. Plywood, on the other hand is available in various standard shapes and sizes.

- Further, wood being sensitive to moisture, the joints may either expand or contract. These limitations of natural wood can be easily overcome while using plywood.

- Similarly, there is a limitation to the thickness of natural wood. Natural wood cannot be obtained beyond a certain thickness. Plywood has provided a solution to this problem and thus provides a large surface area which is joint-less and is not likely to get affected by moisture unlike natural wood.

- Plywood is available in large size, and hence one can avoid joints in furniture which is impossible in natural wood. Also, plywood is available upto 8ft length. Therefore, it is economical as compared to natural wood.

- Due to the less number of joints, it obviously increases the speed of construction as compared to wood.

- It requires less skilled labour as compared to natural wood.

- Plywood can be easily polished or painted.

- According to the Plywood.com, plywood can last upto 10 years or even more. However, if it comes in contact with moisture or termite, its quality may get affected, and it may deteriorate. The life of natural wood is more as compared to plywood.

Final Thoughts:

Experts use plywood due to its unique properties like;

- High strength and stability

- High resistance to impact

- Resistance to water, chemicals, fire, and heat

- Flexibility in shape, size and thickness makes it fit for every requirement

- No shrinking, swelling and wrapping

- Durable

- Cost-effectiveness

- Environmentally friendly, minimizes wastage of wood

Thus, plywood is a versatile material. The cost of plywood varies depending upon the properties and purpose. In routine interior work, one can use ordinary plywood which is economical and that for specific purpose like resistance to water, use standard waterproof plywood which will have a higher cost as compared to the regular one.

Different grades of plywood are available in the market, and one has to choose the right grade depending as per one’s requirement.

So, if you are planning to make furniture or build a home, you need to give aserious thought to plywood!