The Last 2 decades have seen enormous advancement in batching of concrete particularly in High Strength Concrete and High-Performance Concrete which leads to the development of high-grade Design Mix Concrete. Batching is the process in which concrete ingredients are proportionate on the basis of weight or volume for making the durable concrete. Know more about batching of concrete. Batching helps to improve the workability of fresh concrete and eliminates the problem of segregation or bleeding in concrete. It provides excellent finished surface i.e. exposed concrete. It also saves the cost of the project by minimizing the wastage of materials. Know more about the importance of batching of concrete.

Batching of concrete can be carried out by volumetric batching or weigh batching. Here we discuss “What is volumetric batching of concrete?” and “Can we get the better quality of concrete by volumetric batching of concrete?”

In volumetric batching of concrete, the ingredients of concrete are measured by their volume before they are mixed for making the durable concrete. The concrete ingredients are measured in measurement boxes of standard size. The measurement boxes are also known as “Farmas” or “Gauge Boxes”.

Workers use troughs for measurement of concrete ingredients on site. But, it is not a proper way to measure the quantity of concrete ingredients for making designed concrete. To ensure the uniformity of proportions and aggregate grading in succeeding batches, the proper and accurate measurement of all the material used in concrete making is necessary.

For volumetric batching, it is convenient to make steel or wooden boxes (farmas) of various sizes/ volumes. In an ideal case, the volume of the farma is made equal to the volume of one bag of cement i.e. 35 litres or multiple thereof. The farmas are made comparatively deeper with narrow surface rather than shallow with the wider surface to facilitate easy levelling of the top level. The internal dimensions of the boxes shall be generally 35x25x40 cm deep or as otherwise approved by the Engineer-in-charge.

It is advisable to have boxes of various sizes readily available at site so that any adjustment which is required to be made by way of change in concrete mix design or due to bulkage of sand can be done easily. It is also advisable that during the measurements of aggregates, the measurement boxes which are filled with aggregates should not be shaken, rammed or heaped.

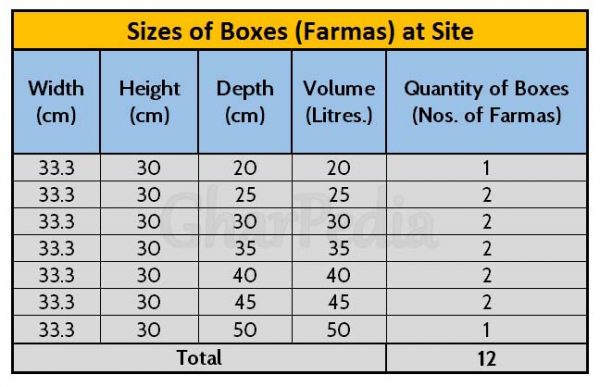

It is generally recommended to have the following sizes of boxes (farmas) at site:

The volumetric batching of aggregates can be reasonably accurate if the site has mobilised the above sizes of boxes (gauge boxes).

Measurement boxes are prepared based on the volume of cement bag. Hence if you need concrete of proportion 1:2:4, you need 1 Bag of cement, 2 Measurement boxes (farmas) of sand, 4 measurement boxes (farmas) of coarse aggregate & 25 litre water (if water cement ratio is 0.5).

Batching of Cement

Cement is always batched by weight. Mostly cement is measured in terms of bags which weights 50 kg and has the volume of 0.035 cum or say 35 litres.

Actual volume of a given weight of cement depends upon how it is filled into the farmas. The density of cement may vary from about 1.12 g/cm3 if it is lightly poured into the farma and 1.60 g/cm3 if tamped down sufficiently hard. Hence cement is not measured by the volume.

Batching of Aggregates

Fine aggregates and course aggregates can be measured by volume. Volume of fine aggregate (sand) in a loose condition weigh much less than the same volume of dry compacted fine aggregate (sand). Know more about bulkage testing of fine aggregate (sand).

The reduction in the ratio of sand causes a reduction in the quantity of concrete produced with each bag of cement.

Batching of Water

Proper control of mixing water is also important for concrete making. The strength and other desirable properties of a concrete mix depend entirely upon ratio of the quantity of water used to the bag of cement.

Water is measured either in kg. or litres as may be convenient. In this case, the two units are same, as the density of water is one kg. per litre. Water shall be measured by volume in a calibrated tank or container.

How much water is required to make a concrete?

The quantity of water required is a product of water/cement ratio and the weight of cement; for an example, if the water/cement ratio of 0.5 is specified, the quantity of mixing water required per bag of cement is 0.5 x 50.00 = 25 kg. or 25 litres.

It is difficult to measure finer material in terms of volume. Hence volumetric batching is not a preferable method for proportioning the ingredients of concrete. Volume batching of concrete may be allowed only where weigh batching is not practical and for unimportant concrete or for any small job. As the strength and durability of concrete is largely dependent on proportion of ingredients and water cement ratio, weigh batching is must and recommended in place of volumetric batching of concrete.

Know more about Weigh Batching of Concrete.

Must Read:

7 Lab Test on Aggregate Should Satisfy for Use in Concrete

15+ Types of Cement Used in Modern Construction