Once mix design is established, the first task is to batch materials. Batching is the process of measuring and combining required ingredients of concrete by either by weight or by volume as per the mix design and introducing them into a mixture to produce a uniform quality of concrete.

The proper and accurate measurement of all the material used in concrete making is necessary to ensure uniformity of proportions in succeeding batches.

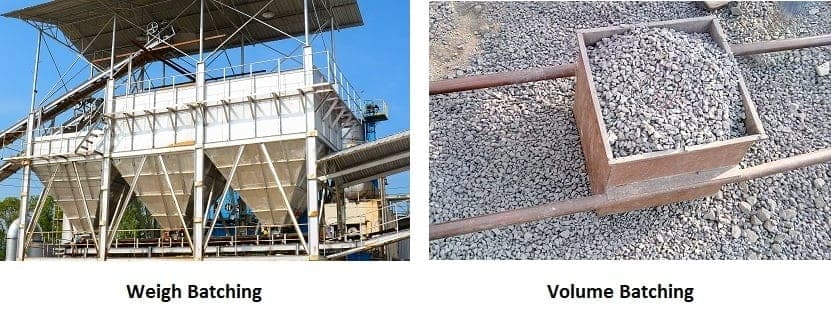

Comparison of Weigh Batching and Volumetric Batching

01

- The concrete ingredients are batched/ proportioned based on weight.

- The concrete ingredients are batched / proportioned based on volume.

02

- Batching by massis achieved by using weigh batching machine/ plant

- Batching by volume achieved by using a constructed gauge boxes (Farmas) for proportioning the materials according to various mix proportions and based on the quantity of material needed per batch.

- In small works gamellas are also used for batching. But it is not recommended for batching of concrete.

03

- Nominal mix is batched by mass using regularly maintained and well-calibrated equipment, therefore high degree of uniformity in proportion of the fresh and hardened state concrete can be achieved.

- When batching by volume is used, possible sources of error could lead to variation in the amount of aggregate in a specific volume and errors in measured volume. These errors often lead to variations in the fresh and hardened properties of concrete as against specified characteristics properties.

04

- Materials batched by mass are exact in measurement taking cognisance of the differences in the material properties.

- Variations in quantity are very much likely for materials. Ultimately affect strength of concrete.

05

- Water for mixing is weighed out precisely as a function of the weight of cement used for each mix proportion. Hence uniform water-cement ratio can be maintained, which plays an important role in achieving strength of concrete.

- The volume of water required for mixing is not often specified. Sometime extra water is added to make concrete workable.

- This makes concrete non uniform and reduces the strength.

06

- Each batch is weighed which makes it easy to detect overruns or incorrect dosages.

- Difficult to detect overruns or incorrect dosages.

07

- The slump of concrete batched by mass is higher than batched by volume for same mix proportion and water cement ratios. i.e. slump varies from medium to very high slump.

- Slump varies from low to high.

08

- For same mix proportion, the compressive strength of concrete batched by mass is higher than that batched by volume at all w/c ratios and for curing ages 7 to 28 days.

- For same mix proportion, the compressive strength of concrete batched by volume is lower than that batched by mass at all w/c ratios and for curing ages 7 to 28 days.

09

- Admixtures are pre-weighed then held in the hoppers ensuring rapid discharge with no impact on batch cycle

- Admixtures are batched directly into correct mix, which could slow batching cycle.

10

- Admixtures can be dosed at any stage of batching and in multiple dumps- thereby achieving optimal performance.

- Admixtures are difficult to batch at certain stages of the batching sequence.

11

- Concrete is of uniform and consistent quality.

- The quality of concrete may differ because of bulkage of fine aggregates (Sand) and therefore concrete is not uniform and consistent.

12

- More precise method.

- Less precise method.

13

- Need skilled labours

- No need to required skilled labours.

14

- Operation difficult.

- Easy to operate.

15

- Speed of construction is high.

- Speed of construction is slower than weigh batching.

16

- Maintenance cost is high.

- Maintenance cost is practically nil.

17

- This method is expensive.

- This method is cheaper and economical

The choice of batching method depends upon size of job, production rate and standards of batching performance. Traditionally batching is done by volume. Batching accuracy is important. It is however recommended to do weigh batching rather than volume batching. Volume batching may be allowed only where weigh batching is not practical.