Everyone knows that in this era, the construction industry has undergone revolution due to advent of new material. The construction industry is more and more developing with various new construction materials, equipment, techniques etc. All of these construction materials are the base of the quality and durability. Concrete, steel, wood etc. are the major constituents of a building. Concrete is the most essential material which is made by cement, sand, aggregate, water, and concrete admixtures.

Concrete Admixtures & its Use

Concrete admixtures are the natural or the manufactured chemicals which are added before mixing or during the mixing of concrete. Concrete admixtures are also known as concrete additives. Concrete admixtures are used to modify the properties of concrete or give the special properties to concrete in harden concrete as well as to the fresh concrete. Concrete admixtures modify the properties like workability, unit weight, strength, increase or decrease in setting time etc. Concrete admixtures are the natural or the manufactured chemicals which are added before mixing or during mixing of concrete. There are various types of admixtures available easily in the market like concrete plasticizers, retarder, accelerator, Superplasticizer, air entraining admixtures etc.

Air-entraining admixtures are one of the important advancements made in concrete technology. The use of air-entraining admixture has been increasing since 1930 all over the world especially, in the United States and Canada. Due to the recognition of the merits of air entraining admixtures, it has almost come to be considered a necessary ‘fifth ingredient’ in concrete making. It is widely used in all types of construction. i.e. the popular Indian projects are Hirakud dam, Koyna dam, Rihand dam etc. are constructed with air entrained concrete.

Air Entraining Admixtures: How it Works?

Air entraining admixtures modify the concrete properties in plastic stage i.e. workability, bleeding, segregation as well as in hardened stage i.e. resistance to frost action, permeability etc. Air entraining admixtures incorporate millions of non-coalescing air bubbles, which will act as flexible ball bearings and will modify the properties of concrete.

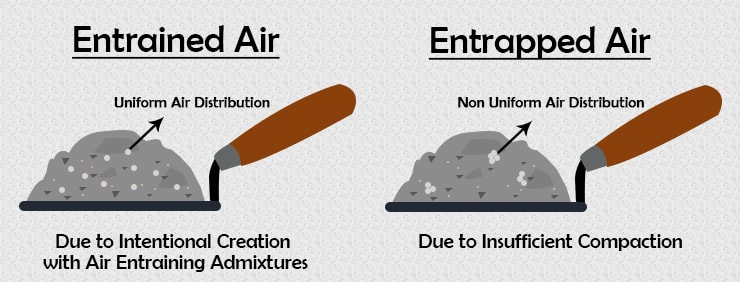

In the concrete air voids can be carried under two groups like Entrained air and Entrapped air.

- Entrained Air: Entrained air means, minute spherical air bubbles of size ranging from 5 microns to 80 microns distributed evenly in the entire mass of concrete.

- Entrapped Air: Entrapped air means, the voids present in the concrete due to insufficient compaction. These entrapped air voids are not uniformly distributed throughout the concrete mass and they may be of any shape and size normally embracing the contour of aggregate surfaces. Entrapped air voids size may vary from 10 to 1000 microns or more.

Common Terminology

01. Air Entrainment

Air entrainment means the intended creation of microscopic air bubbles in the concrete.

02. Air Entrained Concrete

Air-entrained concrete contains billions of microscopic air cells which are produced by using air-entraining portland cement, or by the addition of air-entraining agents, under careful engineering supervision. The volume of entrained air is usually between 4 % and 7 % of the volume of the concrete. For the special conditions, these percentage may be varied as per requirements.

Advantages of Air Entraining Admixtures

Air entraining admixtures increase the slump (workability) of concrete by using less amount of water which is very important for placing of concrete in difficult condition. It gives the high resistance to freezing and thawing action. Air entrained admixtures has no positive or negative effects on setting time of concrete and corrosion in the reinforcements because it doesn’t contain chloride or any other component which can increase corrosion. Thus, it is preferable for use in reinforced concrete structures.

Also Read:

What is the Concrete Slump Test?

Chloride Content Test For Concrete Structure Durability

Disadvantages of Air Entraining Admixtures

Use of air-entraining admixtures can decrease the strength of the concrete, which is the only concern. Generally, compressive strength may decrease by approximately five 5% when the air content increase by around 1%. Hence, it’s essential that air content is closely controlled.

Application of Air Entraining Admixtures

Air entraining admixtures is used for various purpose like,

- Used in concrete roads,

- Runway concrete,

- Airport construction,

- Dams,

- Water treatment plants,

- Water tanks and channels,

- Where concrete is poured to ensure imperviousness,

- In producing concrete with freeze-thaw resistance,

- In production of light hollow concrete,In ready-mix concrete.

In other words,

- It’s used in the places where the weather is not normal (abruptly changing), to protects the concrete from varying weather action.

- It’s used in the marine area construction.

- It’s used in the places where chemical reaction can easily take place.

Effects of Air Entraining Admixtures

01. Workability

Air entraining admixtures improves workability and makes easier place ability in difficult situations with lower water-cement ratio.

02. Unit Weight

In the comparison of ordinary concrete which have the same workability and strength, air entrained concrete has lowerweight. The major reason for the reduction of the density of air entrained concrete is, it contains 5 % less of solid material due to the entrained air.

03. Permeability

The entrained air improves the permeability of concrete. Major reasons arethe modification of pore-structure of the air entrained concrete, reduction of water channel due to a reduction in bleeding and the reduction of water/cement ratio etc.

04. Strength

Generally, it can be stated that the air entrainment in concrete reduces the compressive strength of concrete.

05. Resistance to Freezing and Thawing

The high resistance of hardened concrete to scaling due to freezing and thawing action is the greatest advantage of using air-entrained concrete.

06. Segregation, Bleeding and Laitance

Segregation, bleeding and laitance of concrete are the different appearances of loss of homogeneity and it will begreatly reduced by air entrainment.

07. Chemical Resistance

The air entrained concretehas greater resistance to chemical attacks ascompared to the normal concrete because of lower permeability and absorption.

08. Sand and Water Content

The minute spherical air bubbles act as fine aggregates and allow the reduction of sand.The reduction of sand further enables the reduction of water requirement without harming the workability and slump.

09. Alkali-Aggregate Reaction

Air entrainment reduces the alkali-aggregate reaction. Use of air entraining agent has been recommended for controlling expansion due to the alkali-aggregate reaction in mortar and concrete.

10. Durability

The knowledge of air entrainment of concrete is required to improve the durability of concrete structures used in marine conditions.

Precautions

The following precautions or factors need to be taken care when using air entraining admixtures.

- Types of aggregate and amount of the aggregate used in concrete,

- Types of cement and amount of cement,

- Fineness of cement,

- Water-cement ratio,

- Temperature

- It is suggested to conduct the required tests and adjust the amount of air entraining admixture so that the mixture has an air content by 4-6% as measured with an air meter in the laboratory environment. Because the excessive amount of admixture has negative affect on the strengths of concrete

- It is used by either adding into the of water used for concrete or directly mixing it into the fresh low-slump concrete. It should not be directly added to the dry mixture.

Air Entraining Agents

The following air entraining agents are used to makeair entrained concrete.

- Natural wood resins

- Various wetting agents i.e. as sulphonated organic compounds and alkali salts/sulphated

- Vegetable and Animal fats and oils, i.e. olive oil and their fatty acids such as stearic acid and oleic acids.

- Animal and vegetable fatty acids.

- Water soluble soaps of resin acids,

- Various materials such as the sodium salts of petroleum sulphonic acids, hydrogen peroxide and aluminium powder, etc.

There are a number of commercial air entraining agents available in the market such as,

- Vinsol resin

- Darex

- N Tair

- Airalon

- Orvus

- Teepol

- Petrosan and Cheecol

From all the above,Vinsol resin and Darex are widely used in the market.

Air entraining admixtures improves the concrete quality, increases workability without adding much water, decreases permeability, allows reduction in sand and cement content, reduced unit weight. Hence, it is used broadly in all types of construction.

Also Read:

Ready Mix Concrete (RMC): High Speed Concrete Construction without Sacrificing Quality

Self-Compacting Concrete | High Performance Concrete

Basics of Fibre Reinforced Concrete

Image Courtesy: Image 1