While undertaking a building construction, a systematic electrical plan too is essential. An electrical plan must be designed to ensure that all the outlets, lighting systems, and power needs work efficiently.

What is Electrical Chasing?

Electrical chase is a technique used for cutting proper channels in masonry or concrete. Chasing is a continuous recess within the floor, ceiling and walls for the required pipe work and conduit.

In electrical chase, the channels of around 50 to 100 mm width and 50 to 75mm depth are carved in the masonry or concrete elements to place the electrical conduit and other services of house and conceal them in the walls for better aesthetics.

Tools Used in Electrical Chasing work

Electrical chasing requires some professional chasing tools which most of the electricians carry with them. Some of the commonly used chasing tools for electrical chasing are-

- Chase cutter

- Chisel

- Lump hammer

- Large bolster

- Medium bolster

How is Wall Chasing Done?

During the floor or wall treat, hand-held cutting tools provided with a double diamond blade are used to cut two slots of specific depth and width in the brickwork. The Centre part of concrete masonry is removed by using a small breaker or hammer drill like these on ToolsFirst. This technique is quick and dust-free.

How to Cut Electrical Chase?

Cutting the electrical chase is a simple job and require simple chasing tools. Basically, an angle grinder with two parallel cutting blades with a depth setting is used. The depth gauge simply sets and runs the grinder up, down or across the wall making two parallel cuts. The waste between the cuts is knocked out with the use of a cold chisel.

According to ‘DMRC’ (Delhi Metro Rail Corporation Limited) Electrical Standards & Design Wing, 2015 there should be a minimum of 10mm width between two chases. The Depth of full thickness of plaster should be minimum 6mm over conduits.

Guidelines for Cutting Electrical Chases in Brick Wall

01. Cutting of electrical chases in one brick thick and thicker load bearing walls

(a) As far as possible, the services should be planned with the vertical chases. Horizontal electrical chases should be avoided, as they reduce the strength of the wall.

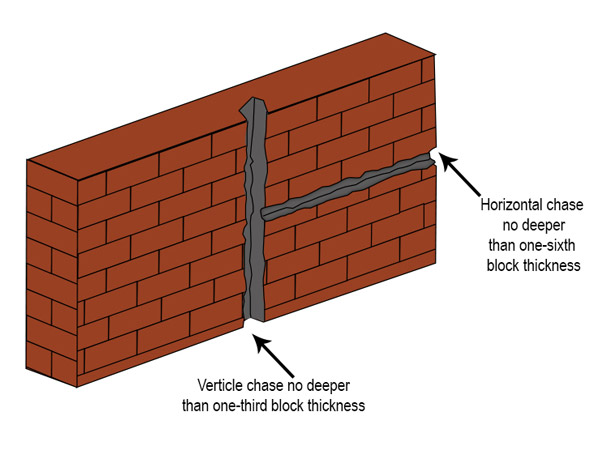

(b) The depth of vertical chases and horizontal chases should not exceed one-third and one-sixth of the thickness of the masonry respectively.

(c) If horizontal chases are unavoidable, then it should be located in the upper or lower one-third of storey and not more than three chases should be permitted in any stretch of a wall.

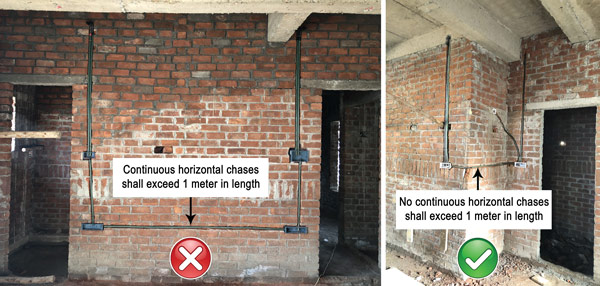

(d) No continuous horizontal chase should exceed 1 meter in length.

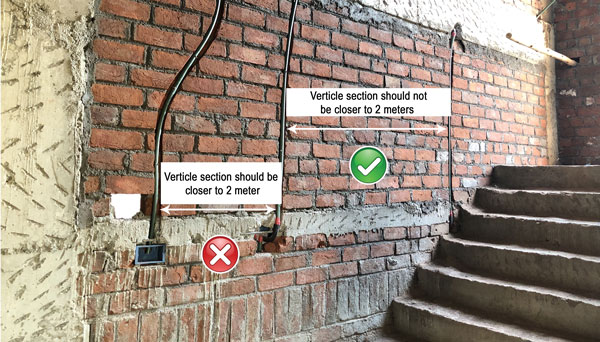

(e) Vertical chases should not be closer to 2 meters in any stretch of a wall.

(f) Electrical chase should be kept away from bearings of beams and lintels.

(g) If unavoidable, stresses in the affected area should be checked and kept within the permissible limits.

(h) Vertical chases for fixing electric conduits, I pipes or a recess for fixing electrical metal boxes should not be cut within 1.5 feet from the edge of the wall.

02. Cutting of Electrical chases in half brick thick load bearing walls

Half brick thick walls are normally not used as load bearing wall, but if at all used, chases should not be permitted in such load bearing walls. Ideally, no recessed conduits and concealed pipes shall be provided in load bearing walls having a thickness of half-brick only.

03. Cutting of chases in half brick non-load bearing wall

Services should be planned with the help of vertical chases. Horizontal chase should be provided only when vertical chase is not possible

How to Fill Electrical Chase?

Once the cable is installed, use a paint brush to wet the sides and back of the chase by using clean water, and then apply a coat of neat PVA adhesive to the sides/back of the chase and conduit/ pipe. This will aid the adhesion of the filler.

As a filler, the materials to be used are:

- A strong sand/ cement mix (3:1:1 – 3 part of soft sand: 1 part of sharp sand: 1 part of cement).

- One coat of plaster or patching plaster.

- A standard decorator’s filler.

- If applied to a deep chase, both the plaster and filler may sag and hence they need to be built up in layers.

The chases must be filled from the back and around the conduit/ pipe from the front. A small trowel will help push the filler into the back corners and behind the conduit/ pipe. Use the trowel across the sides of the wall surface to cut off the filler to the line of the wall. If channeling is used, there is no need to try to fill the chase behind it.

If the wall is to be tied, there is no need to give a fancy finish to the wall. But if the wall is to be painted or papered, cut back the surface of the filler by about 3 mm before it fully hardens.

Electrical chases can also be filled with a plaster called patching plaster or one coat plaster. This can generally be applied in coats up to 50 mm thick. If there is a deep chase, build the fill up in layers. If using one coat plaster, make sure that you wet the chase really well before applying it. The plaster will dry out quickly and crack badly if its moisture content is not maintained. Recon fibers with mortar can also be used for filling the chases.

In sum up, if you follow the above guidelines, you will not face any major problem in the future due to chases in wall.