Building material plays a very important role in this modern age of technology. No field of engineering is conceivable without its use. Bricks are one of the oldest building materials which are still a prominent and leading building material because of its low cost, wide availability, durability and easy handling. Most commonly used brick is Clay bricks which are used for building interior and exterior walls, piers, partitions, footings and other load-bearing structures.

According to ‘R. Barry’ (Author of The Construction of Building), the word ‘brick’ is used to describe a small block of burnt clay of such a size which can be conveniently held in one hand and is slightly longer than twice its width.

The common burnt clay bricks are usually pleasing to look at with warm colours ranging from cream to orange to sandy and to brown or even blue brown in colour. When built into a wall, interesting but, simple and pleasing patterns appear, just like people who all have one nose, one mouth, two ears and two eyes but, no two person looks exactly the same. So, each brick although simple in shape, has its own individuality.

As bricks are most common, basic and essential unit for house construction, they must be of good quality. The quality of bricks may vary depending upon the raw materials used and also in its manufacturing process. Good quality bricks should possess both physical and chemical properties.

In this article, we have discussed the qualities of a good brick.

Qualities of a Good Brick

01. Brick Earth

Brick earth should be free from pebbles (kankars), stones, organic matter, saltpeter (potassium nitrate) and other harmful chemical, as it makes poor quality of bricks.

02. Size of a Brick

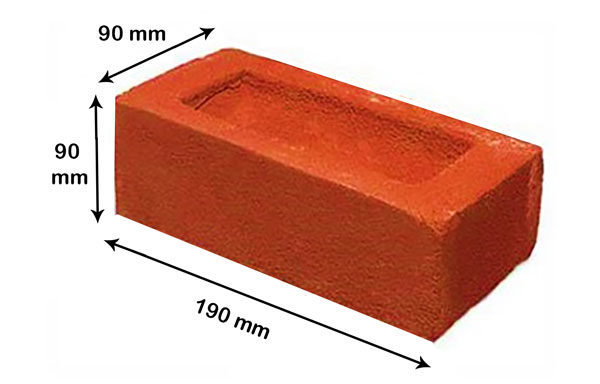

A good brick should have a uniform size with plain and rectangular surfaces and should be parallel from the sides having sharp and straight edges, as per standards. A brick should not exceed 3 mm tolerance in length and 1.5 mm tolerance in width and height. According to ‘IS 1077: 1992’ (Common Burnt Clay Building Bricks – Specification), the standard or conventional size of clay brick is 190mm X 90mm x 90mm. However, the size of bricks may vary from country to country and from place to place even in big countries like India.

03. Shape

The shape of a brick should be uniform. The edges of a good brick should be sharp, straight and at a right angle. However, bricks used for special purpose may be either cut or manufactured in various other shapes. These are generally modifications of rectangular shapes.

04. Colour

There are wide range of colours, such as red, white, grey, brown, purple, blue and black, along with some intermediate shades. According to ‘W. B. McKay’ (Author of Building Construction), the colour is influenced by the chemical constitution of the clay, its temperature while burning, the atmospheric condition of kiln, and staining. Good quality bricks should be well burnt and should have a uniform colour throughout the body of brick. Over burnt and under burnt bricks loses the uniformity of colour on its surface and strength. Very dark shades of red indicate over burnt bricks whereas, yellow colour indicates under burnt bricks.

05. Frog in Brick

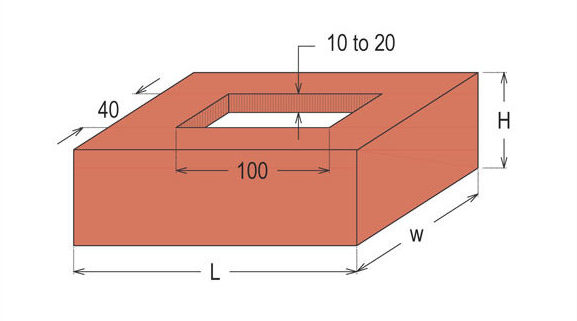

A good quality brick should have a proper frog (Depression made on the face of bricks during moulding), so that the mortar can be properly filled in the frog. The size of the frog should be 100 mm in length, 40 mm in width and 10 mm in depth.

06. Texture and Compactness

There is a considerable variation in the texture of bricks. The good bricks should have a pre-compacted and uniform texture. The surfaces of brick should not be too smooth to cause slipping of mortar. A fractured surface should not show cracks, holes, grits or lumps of lime.

07. Compressive Strength

The compressive strength of brick depends upon the composition of the clay and degree of burning. As per ‘National Building Code of India’ (1983), the compressive strength of brick should be of minimum 3.5 N/mm2 i.e. 35 Kg/cm2. We have also written an article on how to check the compressive strength of brick.

08. Hardness

Bricks should be sufficiently hard. No impression should be left on the surface of a brick when it is scratched with fingernails.

09. Water Absorption

Water absorption of a good brick should not exceed 20 % of its dry weight when immersed in water for 24 hours. Bricks, when soaked in water for 24 hours, should not show deposits of white salts, when allowed to dry in the shade. Bricks should not absorb water more than 20 per cent by weight especially for bricks of the first class and 22 per cent by weight for bricks of the second class when they are soaked in water for 24 hours. Testing should be done in the laboratory in order to check water absorption of brick.

10. Soundness

When the brick is struck with a hammer or with another brick, it should give a metallic ringing sound.

Shri Mahadev Desai (CMD of Sthapati Designers & Consultants Pvt. Ltd., a leading multi-disciplinary consultancy firm in India) suggested a simple way to judge the qualities of bricks at the site. He said, when you visit any construction site, just observe the no. of quantities of brickbats (broken pieces of bricks) near the stacks of bricks or observe the same when the bricks are being unloaded from trucks. If the quantity of brickbats (broken pieces of bricks) is substantial, naturally the quality of bricks is not good. He said as such there should be no brickbats at all. You can do the same even when you visit brick kiln or brick sale depot. Such simple observation will help you decide the qualities of bricks immediately and on-site by one observation.

To sum up, the aforementioned are some qualities of good bricks which every homeowner should know before using it in construction to achieve the best results. Good quality bricks enhance the quality of brickwork. In the area, where clay for bricks is available easily, brickwork will be cheaper. But clay is not easily available in rocky, coastal or dessert prone areas. At such places, alternative building material like fly ash brick, AAC block and the dry wall should be used.

Must Read:

Your Mentor to Guide You to Buy Bricks

40+ Masonry Tools Used in Masonry Work of Your Home!

Difference Between Brick Masonry and Stone Masonry