Construction and advancement of civilization is complementary to each other. Since the days of early onset of human society development, the idea of home came in practice, and along with it the conception of walls and roof has been introduced as an integral part of construction.

The walls are predominantly made with masonry. It is one of the oldest and crucial methods of construction human civilization has mostly relied on. Masonry is in the trade since ancient time. Especially, brick masonry i.e. using clay for bricks is the most common and widely used method of Masonry worldwide even today.

Bricks are the most common unit components of a construction of the masonry walls in a structure. With the advancement of time, the art and technique of brick masonry have gone through a sea change, and has become extremely improved.

Advanced brick masonry is typically produced by laying the bricks in layers which are constructed by putting these units in a horizontal pattern and bonding them with mortar.

Brick masonry is classified into first class or second class according to the type of bricks used and according to the method of laying. The strength of masonry work, however, depends largely upon the type of material used in masonry, nature of workmanship and related supervision. In fact, unprofessional and unskilled workmanship coupled with lack of supervision may lead to faulty construction in spite of using best quality building materials.

According to ‘R. Barry’ author of The Construction of Building, Brick masonry walls offer basically two real-life purposes:

01. It acts as the barrier against the climactic turbulence like rain and wind. Also, it prevents the excessive loss of heat in cold weather and again keeps functioning as the insulation of heat intrusion during very hot weather, and

02. to provide adequate support to floors and roofs.

Hence, it is necessary to construct quality brick masonry wall to stay safe and external weather proof.

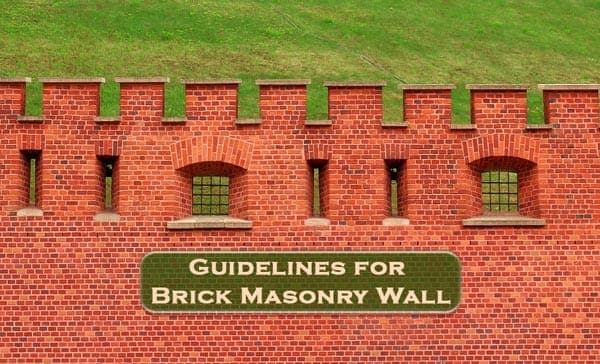

The general guidelines for offering stable and professional quality brick masonry work are shared here. Let’s take a look:

Good Quality Bricks are the prerequisite for constructing a Brick Masonry Wall

- The bricks used in a brick masonry wall are expected to be sound and hard, and adequately burnt along with uniform size, shape and Colour.

- Bricks should not have cracks or flaws or fractured surface. It is expected that it is free from holes, grit or lumps of lime, etc.

- The surface of the bricks should remain un-tampered by fingernail abuse.

- Good quality bricks, if struck together, should produce metallic ringing sound.

- The bricks should be that strong enough that if dropped from a height of 90 to 120 cm on the ground, the bricks will stay unharmed.

- The bricks should not, as a rule, absorb water more than 20% of their weight when dry if immersed in water for twenty-four hours.

- According to ‘Indian Standard/IS 2212’ (1991) all the bricks should be thoroughly soaked in clear water immediately before use for a considerable period so the water gets into the full depth of the bricks. This water absorption not only helps in removing the dirt, dust, and other soluble salts (which may cause efflorescence) from the bricks but also the process reduces the general tendency of bricks to absorb water from the wet mortar.

- If masonry is to be carried out in mud or fat lime mortar, the bricks should not be soaked in water before their use.

Scaffolding for Brick Masonry Wall

- In order to carry out the brickwork at a higher level, double scaffolding is generally used. Single scaffolding may result in leftover holes in masonry which in turn may cause unwanted leakages.

Good Quality of Water is necessary for the stability of the Brick Masonry Wall

Water is one of the main factors in standard Brick Masonry. Few rules about water quality are to be followed:

- Water used in brickwork should be potable and free from salts.

- Water used for making brick should also be salt-free.

- Potable water should be used for mortar, curing and for the manufacturing of bricks. If water quality is compromised, efflorescence may get prominent.

Quality of Clay for Brick

- Clay, used for manufacturing brick, is expected to be free from salts.

Art of Laying of Bricks in a Brick Masonry Wall

- The bricks should be laid on a full bed of mortar.

- The bricks need to be pressed slightly into the bed mortar to ensure desired adhesive effect.

- All the courses should be laid truly horizontal and all the vertical joints should be truly vertical.

- Unless brick-on-edge is specified, the bricks should be laid on their proper beds with their frogs pointing upwards.

- The courses of bricks are used at the plinth, window sill, and floor/roof level; eventually the top of parapet wall should invariably be laid with “brick on edge”.

- As a general practice, quoin brick should be the headers and stretchers laid in an alternate course. Here the bond is developed by placing a quoin closer next to the queen header.

- According to ‘J.K. Mckay’ author of Building Construction, in brickwork, the brick should be laid with an adequate gap between them on their bed with the frogs pointing upwards so that mortar avails mechanical bond/key between the two layers of bricks.

Joints in Brick Masonry Wall

- All the joints should be properly flushed and filled with mortar so that no cavity stays unattended.

- In case of walls with two bricks or more in thickness, the joints should be grouted as every course in addition to bedding and flushing with mortar.

- The thickness of the joints should not exceed 13 mm in any case.

- The face joints are generally raked to a minimum depth ranging from 10 to 15 mm when the mortar in the joints is still green. This is done to provide a proper key for the plastering or pointing.

Bond in Brick Masonry Wall

- No brick-bats should be used in the brickwork except it becomes absolutely necessary to obtain the specified bond due to size limitations.

- Brickwork is generally laid in the English bond. In all cases, it should be ensured that the ideal bond quotient is maintained throughout the work.

Quality of Mortar for Brick Masonry Wall

- Only specified standard quality of mortar should be used in the brick masonry wall, taking professional care so that uniform mortar joints get created throughout the construction work.

Raising of Brick Masonry Wall

- The progress of work at the time of raising masonry should be such that all the connected brickwork is carried out in uniform layers at one level.

- It is better to be ensured that the wall will not rise more than 100 cm than the rest of it in a day. If this restriction cannot be adhered to, the work should be raked back according to the bond.

- The walls have to be raised up in truly vertical style.

- The buttresses, counterforts, etc. should be built up step-by-step, maintaining a proper bond with the main wall, and they should not be added or joggled afterwards.

Use of Timber in Brick Masonry Wall

- When timber floor or roof is built to offer support on brick masonry walls, the ends of the timber joists (supporting the floor or roof) should always be rested on corbels or brackets.

- If the ends of timber joists have to be built into the wall itself, it is necessary to apply suitable preservative to the embedded portion of the joists. In addition to this special treatment, some space should be left around these spots to minimize the risks of termite attack and to ensure the provision of free circulation of air.

Updating Existing Brick Masonry Wall

- If an existing wall has to be strengthened by making it thicker, (20 cm × 20 cm × 10 cm= (dimensions of one brick) generally recesses are built on the existing wall. These recesses are staggered carefully so that one recess is made in every square meter of the wall. This enables the new brickwork to properly bond with the old one. This method of bonding is known as back-bonding.

- If it is planned that the length of the ongoing wall construction may get increased in the near future, the wall-work is kept paused with a toothed end. This is necessary to ensure seamless bonding between the old and the new brickwork once the wall building will be resumed again.

Expansion Joint in Brick Masonry Wall

- It is generally found that an average day/night temperature difference is of about 10⁰ C to 20⁰ C. If it is around 20⁰ C or more, a brick masonry wall may expand up to 10/20 mm per every 30 meter-length of the wall. Hence, it is advised that a minimum 12 to 18 mm wide expansion joint should be provided in every 30 to 45 meters gap on the length of the wall.

Reinforcement in Brick Masonry Wall

- Half brick partition walls should be protected with suitable reinforcement. These support systems have to be placed at every fifth or sixth course of the brick masonry wall. These reinforcements may be used in the form of mild steel bars, flat bars, hoops iron, expanded mesh, or steel fabric, etc.

Finishing in Brick Masonry Wall

- Plastering on brick masonry wall is a requisite and it should be done after about 28 days of completion of brickwork. This time gap permits adequate interim period for the expected and optimum shrinkage in masonry and concrete to take place before plastering is finally carried out.

- In works where plastering or pointing is not coveted, the mortar joints should be struck flush and finished at the time of laying.

Curing of Brick Masonry Wall

- All the finished brick masonry wall should be kept hydrated for at least a minimum of seven days’ time. According to ‘Bureau of Indian Standards’ (SP 20, 1991) Curing should be continued up to a minimum period of 7 days from the date of laying of masonry. However, in case of masonry using rich cement mortar (1: 4 or richer), where strength of masonry is a matter of special consideration, the period of curing should be extended up to 10 days in dry weather (when humidity stands less than 50 percent).

Summing up, the list provided above is a professional checklist and quite helpful in order to complete a top-quality brick masonry work. Brick masonry wall constructed according to these guidelines will give you the payback of investment done and it will reduce at large the risk of cracks, leakages, etc. in brickwork.

Must Read:

Investigation & Repairing of Cracks in Brickwork

What are the Pros and Cons of Masonry in Construction?

Comparison of Red Bricks vs AAC Blocks vs Fly Ash Bricks vs Solid Concrete Blocks vs CLC Blocks