Masonry work dates back to ancient times, so are the masonry tools. According to Prof. ‘M. M. Goyal’ (Author of Construction Handbook for Civil Engineers and Architects), masonry is the proper assemblage of masonry units bonded together with mortar. At the construction site numerous construction tools can be seen, each having specific purpose. We use these tools in the construction process to complete the particular work.

Masonry work requires tools for various purposes, i.e. for handling of mortar, for the dressing of stone, for cutting of bricks to get required shape etc. As it goes with traditions in existence since the days of the Ancient Indian and Egypt, masonry deals with some common elements as crushed stones from the earth and simple metal tools. Historically, wood also played a crucial role in construction, not only for structural supports but also for fuel in the process, much like how birch firewood logs might be used in a lime kiln for mortar production or to provide warmth on a construction site.

These tools are also known by their regional names depending upon local customs of the region for example, spades are known as “phavadas”, mortar pan is known as “ghamela” and so on.

Here we have listed out and classified basic masonry tools based on their application in the construction process.

Common Masonry Tools used in Masonry Construction

1. Trowel

2. Corner trowel

2A. Outside Corner Trowel

2B. Inside Corner Trowel

3. Setting Out Square or Mason Square

4. Plumb Rule and Bob

5. Spirit Level

6. Line and Pins

7. Water Level

8. Boning rods

9. Spades (Phavadas)

10. Mortar Pan/Ghamela

11. Jointer

Masonry Tools for Stone Masonry

12. Bevel

13. Pick Axe

14. Crow Bar

15. Chisel

15A. Wood Handled Chisel

15B. Drafting Chisel

15C. Tooth Chisel

16. Boaster

17. Hammer

17A. Spalling Hammer

17B. Mash Hammer

17C. Mallet (Wooden Hammer)

17D. Dummy (Iron Hammer)

17E. Scabbling Hammer

17F. Waller’s Hammer

17G. Club Hammer

18. Pitching Tool

19. Gauge

20. Punch

21. Point

22. Claw tool

23. Nicker (Broad Tool)

24. Jumper

25. Wedge and Feathers

26. Gad

27. Drag

28. Saw

28A. Hand Saw

28B. Circular Saw

28C. Cross-cut-saw

28D. Frame Saw

Masonry Tools for Brick Masonry

29. Brick Hammer

30. Lump Hammer and Bolster

31. Double-end Comb Hammer or Skutch

32. Straight Edge

33. Brickwork Gauge Rod

34. Bricklaying Trowel

Common Masonry Tools used in Masonry Construction

01. Trowel

The basic masonry trowel is made up of stainless steel with a plastic/ wooden handle. The ends of trowel may be bull nosed or pointed. This is used to lift and spread mortar in joints during masonry construction. There are different kinds and sizes of trowels used in masonry work.

02. Corner Trowel

It is one of the common modifications of the basic trowel. It is used for shaping corners of the wall. They are two types of Corner Trowel.

2A. Outside Corner Trowel

There are different designs of outside corner trowel but the one shown at left side with shorter flanges is the most common. These outside corner trowel can have a sharp 90-degree angle or a bull nose (rounded) edge.

2B. Inside Corner Trowel

These are more common than the outside corner trowel, just because corner aid is used on the outside corners. They have standard features, comparable to an outside corner tool but also have adjustable models that can get wider or narrower, depending on the angle of the corner.

03. Setting Out Square or Mason Square

It is used to set out right angles at the corner of masonry wall. This is very important and basic tool used in masonry work. This tool has “L” shape. It is made of flat steel having each arm about 0.5 m long.

04. Plumb Rule and Bob

This basic masonry tool is used to check the verticality of walls. It consists of a string tied to a weight at bottom called bob and straight wood board with uniform edges called plumb rule. On its center a groove is provided in which plumb bob is placed. When the rule is placed vertically with the wall, the plumb bob must be in the groove line indicating the perfect vertical wall. If the plumb ball does not fall on the groove line, the wall will not be vertical.

05. Spirit Level

It is used to check the horizontality and verticality of the surfaces. Spirit level is made of hard plastic or wood with bubble tube in the middle. The bubble tube is partially filled with alcohol in such a way that, an air bubble is formed in it. The spirit level is placed on surface of masonry wall and bubble is checked. The surface is called leveled when the bubble in the tube settles at middle of tube.

06. Line and Pins

It is used to maintain the alignment of the work-in-progress. Line and pins consist of a string whose ends are connected with two solid metal rods with pin points. It is used to level line and the alignment of brick course while brick laying in brick masonry work.

07. Water Level

It is used to transfer and check level. It is a simple tool to measure the level at two different points. It is a tool that works on the principle that water always seeks its own level. It consists of flexible tube with liquid, and the liquid at both ends will be at the same level whether you’re holding them together or spreading them a hundred feet apart.

08. Boning rods

They are It is used for levelling from two fixed points in surveying. It consists of an upright pole having a horizontal board at its top, forming a ‘T ‘shaped rod. Boning rods are made in set of three rods, and many consist of three ‘T’ shaped rods, each of equal shape and size, or two rods identical to each other and a third one consisting of longer rod with a movable or detachable ‘T’ piece. The third one is called traveler or traveling rod.

09. Spades (phavadas)

They are used to mix mortar and also used to place cement, mortar, concrete in head pan. Spade is also used to dig the soil for foundation trenches etc. It consists of metal plate at the end of long wooden handle.

10. Mortar Pan / ghamela

Mortar pan is commonly used in construction sites and is made of iron or plastic. It is a vessel made of rigid plastic or steel used to hold or carry sand, cement, mortar and concrete. It is also used to mix mortar and to lift mortar on working site. To use a mortar pan, fill it with a quantity of material i.e. sand, cement, mortar etc. that you are comfortable with carrying.

11. Jointer

A jointer in masonry construction is a tool in the form of a striking iron or a striking tool used to finish the horizontal or the vertical mortar joints. A jointer or brick jointer is a hand tool designed to imprint grooves into recently filled mortar joints at the stage when they are starting to set. Using a brick jointer helps to improve and visual impact and the lifespan of the mortar. Jointer is used to refer to any tool which can shape the mortar between bricks.

Masonry Tools for Stone Masonry

12. Bevel

It is employed to set out angles. It comprises of two slotted blades of steel and fixed with each other with thumb screw. It is a tool consisting of two rules or arms joined together and opening to any angle.

13. Pick Axe

It is employed for rough dressing of stones and to split the stones in the quarry. It has a long head pointed at both ends.

14. Crow Bar

It is employed for dressing the surface of stones. This consists of an iron edge with a number of teeth from 3 mm to 9 mm.

15. Chisel

They are used with mallets and with hammers. A chisel is used for normal splitting, roughing out and shaping the stone. Chisels are available in different sizes with bladed, flat, tapered and other shaped chipping points. Blade of chisel is made from iron or metal and the handle is made from wood.

15A. Wood handled chisel

It is used to dress soft stones. A chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting stone by hand. Its handle is made from wood or plastic.

15B. Drafting Chisel

It is a chisel especially used for cutting a border or line at the edge of a stone. They come in different types of size. Grooves are made with the drafting chisel at the all four edges of stone. And, these stones are used in plinths and at corners in building.

15C. Tooth Chisel

Tooth chisel is also used for fine dressing. It is a hand-held tool of metal consisting of a long shaft, with a toothed cutting edge at one end. It is again usually hit with a mallet or metal hammer. The number of teeth on this cutting edge varies, generally between three and five, but a variation with two teeth also exists. The tooth chisel is normally used between roughing-out and finishing, to clear away the rough marks left by the point chisel and prepare the surface for finer work.

16. Boaster

It is also used to cut soft stones. It is a broad-faced or wide-edged masonry chisel. Boasted finish is done by boaster. This type of finish includes intermittent parallel lines which are horizontal or vertical or inclined. Boaster has an edge of width about 60 mm.

17. Hammer

Following are seven types of hammers that are specifically used for stone masonry.

17A. Spalling Hammer

It is a stone mason’s tool. It is a heavy hammer used for cutting, shaping and rough dressing of stones. It has a beveled striking face. It is a large hammer usually with a flat face and straight peen for rough dressing and breaking of stone.

17B. Mash Hammer

A mash hammer is also known as a stone mason’s hammer. It is used to hit and drive chisel for rough dressing of stone. It is double-sided with two striking faces, most often used in stone masonry work. It should only be used to strike stones, but can also be used for such tasks as chipping away mortar in stone masonry. This hammer consists of a wooden handle to which is attached a heavy head, usually made of metal.

17C. Mallet (Wooden Hammer)

It is a basic tool used for shaping of stone. It is a wooden hammer used for driving wooden headed chisels. It usually has a large head.

17D. Dummy (Iron Hammer)

It is used for carving of stones. It has also large round shape head which is made of iron. Its handle is made up of wood.

17E. Scabbling Hammer

Scabbling also called scappling is the process of reducing stone while dressing of stone. In scabbling dressing, only irregular angels are taken off with a scabbling hammer. Hence scabbling hammer is a tool used to break small projections of stones or removing irregular bushings from the face of stone. It has a large head made of iron and wooden handle.

17F. Waller’s Hammer

It is used for removing spalls in stone masonry work. It also consists of iron head and wooden handle.

17G. Club Hammer

It is used to strike arrow -headed chisels. It is also useful for light demolition work, driving masonry nails, and for use with a steel chisel when cutting stone. Its weight drives the chisel more deeply into the material being cut than any lighter hammers. It also consists of iron head and wooden handle like other stone masonry tools.

18. Pitching Tool

Pitching tool is a hand driven tool comprising of a long edge with a thick point. The ‘working-edge’ of the pitching tool has a broad flat face that is generally ground to an angle just slightly-off the perpendicular. It is mainly used to make stones of required size. If the carving block of the stone has flat-sawn faces, then this tool can be used to remove a great deal of waste material at the initial stages of carving.

19. Gauge

It is employed to dress stones for spring, course, cornice, coping etc. It is made of metal.

20. Punch

It is employed to dress the hard stones roughly. It is one-piece rod-shaped tool made from metal designed to be struck by hammer. It’s one end is pointed and other is round shape.

21. Point

It is employed for roughly dressing the hard and tough stones. Point is also used for roughing out areas and knocking off high spots in stones. Point tool is used after any initial work with the pitching tool. Both point and punch are used to rough-out the form but the latter tapers to a small cutting edge of stone whereas the former tapers to a single point of the stone.

22. Claw Tool

It is employed for dressing the surface of stones. This consists of an edge with a number of teeth from 3 mm to 9 mm. Claw tool is used after the coarse carving with the point tool. The claw tool, with its row of pointed teeth, acts like a rake to even out the surface irregularities left by the point. While using this tool, care should be taken to ensure all of the chisel’s teeth are in contact with the stone, in order to prevent breakage.

23. Nicker (Broad tool)

The mason’s nicker (Broad tool) is made from high quality steel. The blade is thicker and beveled on both sides to create a cutting blade. It is held at right angles to the stone and hit with a hammer to split the stone.

24. Jumper

It is a long drilling tool consisting of an iron bar with a chisel-edged steel tip at one or both ends, operated by striking it against the rock, turning it a little with each blow. They are used to bore holes for blasting purposes in a quarry by quarry workers and masons.

25. Wedge and Feathers

It is an oldest yet, one of the best tools to split the stone. It is a three-piece set tool. Each set of tool consists of a metal wedge (also called plug), and two shims (also called feathers). The feathers are tapered and curved at the top and wide at the bottom. When the two feathers are arranged on either side of the wedge, the combined width of the set is the same at both ends. They are employed for cutting the stones after they have been bored with a jumper.

26. Gad

Gad is a small, steel, wedge-shaped tool used for splitting of the stone.

27. Drag

It is employed to level a stone surface. It consists of blades set at alternating angles, between 15 and 30 degrees, over the length of a block of wood. The blades are toothed to provide even removal of surface material. Some drags can be fitted with specially shaped blades to follow convex surfaces.

28. Saw

Following are four types of saw that are commonly used for stone masonry.

28A. Hand Saw

It is used to cut soft stones. It is a saw with wide cross-cut toothed steel blade and wooden/plastic handle at one end. It is used by one hand.

28B. Circular Saw

A circular saw is either hand held or affixed to a substrate. It runs on electricity and is provided with a toothed or abrasive blade/disc which has the ability to cut different materials including wood, stone, brick, metals, plastic by using a rotary motion that spins around an arbor.

28C. Cross-cut-saw

It is used to cut hard stones. It is designed specifically for rough cutting. It has a comparatively thick blade, with large, beveled teeth. Traditional 2-man crosscut saws (felling saws) have a handle on each end and are meant to be used by two people to cut stones.

28D. Frame Saw

This is used to cut large blocks of stones. It consists of a comparatively narrow and flexible blade held under tension within a (generally wooden) rectangular frame called sash or gate. The blade is held perpendicular to the plane of the frame, so that the stone passes through the center of the frame.

Masonry Tools for Brick Masonry

29. Brick Hammer

It is used for rough cutting of bricks in different shapes and sizes. One end of the hammer is square and another end is sharp-edged. It has one flat traditional face and a short or long chisel shaped blade. It is also used to push the bricks if they come out from the course line.

30. Lump Hammer and Bolster

Lump hammer is used for light demolition work or to break masonry. In order to cut brick accurately, a steel chisel with a very wide blade called bolster is employed.

31. Double-end Comb Hammer or Skutch

It is used to remove surplus material after cutting of bricks by bolster, for greater accuracy. The Hammer has two groove components for double sided use. Comb of hammer is a made from iron or similar metal whereas handle is made up of plastic or wood.

32. Straight Edge

Straight edge act as extensors to mason’s level. They are used when levels are shorter than the area that needs to be measured or assessed. The middle section of the top of the straight edge should be horizontally parallel to the bottom section. It is used for checking the straightness of brickwork.

33. Brickwork Gauge Rod

It is similar to straighten edges on which levels of different courses of bricks including sills and lintels are marked. It may be as long as the height of the ceiling. It is used to confirm that courses are maintained at correct levels.

34. Bricklaying Trowel

It is a flat triangular trowel used in bricklaying for cutting brick and spreading mortar or cement. The trowel is also used to tap bricks down on to the bed and can be used for random cutting of soft bricks. They come in various shapes and sizes depending on the task.

Here’s a video to sum up all the points mentioned above:

To sum up, the list of masonry tools is exhaustive. Here we have made an arduous task of listing out the masonry tools and its functions. Proper tools are essential aspect of all constructions, big or small. Though there are a number of tools, most of the masonry tools are the upgraded version of the same old basic tools.

Equipping the construction site with the adequate construction tools is essential to achieve good quality timely results. For every construction activity, there is always an optimal combination of tools, equipment and labour. According to ‘IS 1661: 1972’ (Code of Practice for Application of Cement and Cement-Lime Plaster Finishes), all tools shall be cleaned by scraping and washing at the end of each day’s work, or after use with different materials.

Metal tools shall be cleaned and greased after each operation. The tools shall be examined and thoroughly cleaned before plastering is commenced. Cleanliness is particularly important with cement plasters, where contamination with set material may seriously affect the performance as well as reduce the effective life of the tools.

At last, flick through the below mentioned video on masonry tools:

Must Read:

Tests to Check Compressive Strength of Brick

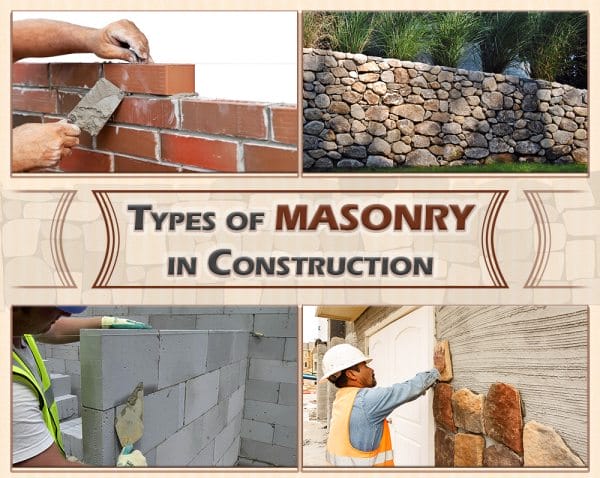

Types of Masonry that can be Used for Construction of your Dream Home

Your Mentor to Guide You to Buy Bricks

Image Courtesy: Image 3(a), Image 3(b), Image 4, Image 5 – acefixings, Image 9, Image 10, Image 12, Image 13, Image 36, Image 40 – lda.lowes, Image 43, Image 44 – ebayimg, Image 45, Image 46, Image 47, Image 48