“Architecture begins when you wisely place two bricks together.”

A home is a place where you can feel comfortable and be yourself, whether it’s an apartment or a bungalow, as long as your heart is there. The home physically is made with different components, including structural components like beams, columns, foundations and non-structural components like doors, windows, tiles, paints. The wall, which can be either a structural or non-structural component, is an essential part of the building that cannot be easily changed once constructed. Therefore, choosing suitable masonry wall units during the pre-construction phase is crucial, given the many options available in the market, such as bricks, stone, concrete blocks, and, wood.

History of Bricks

The earlier Bricks were dried brick, meaning that they were formed from clay-bearing earth or mud and dried (usually in the sun) until they were strong enough for use. The oldest discovered bricks, originally shaped from mud dates before 7500 BC.

According to ‘Frederick S. Merritt’ (author of Building Design and Construction Handbook) Brick is a rectangular masonry building unit, not less than 75% solid, made from burnt clay, shale, or a mixture of these materials.

No other building material can match brick’s elegance and classic style. Bricks are most common and widely used wall units all over the globe, since the soil for manufacturing of bricks is hugely available everywhere except desserts and rocky area. These days many different types of bricks for houses, are available. Hence, we are going to give you information regarding bricks types from which you will be able choose as per your choice and needs.

Bricks are not used only as wall units but they can also be used in paving, floor, cornice, arches, lintel, retaining wall etc. According to ‘R. Barry’ (author of the Construction of Buildings, Volume 7), it is not possible to classify bricks as good or as bad because some are good for one purpose and not for another. “”Bricks can be used to construct everything from homes to outdoor patios and mailboxes to backyard grills,”” says Andrei Newman of Casa Blui.” Bricks may be classified in accordance with their uses, quality, shape, raw material, manufacturing method etc.

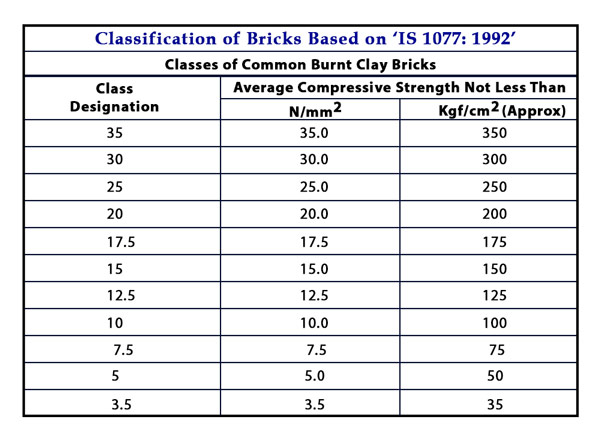

Classification of Bricks Based on code ‘IS 1077: 1992’

Different Types of Bricks Used in Construction

Bricks classifications are based on different criteria.

Classification of bricks is done based on:

- Quality

- Burning of Brick

- Manufacturing Method

- Raw Material

- Using Location

- Weather-resisting Capability

- Purpose of Use

- Shape

- Cavities

- Region

Classification of Bricks Based on Quality

01. First Class Bricks

This type of brick is good quality brick as compared to other bricks. These are made from good quality clay. These types of bricks are regular in shape and size. They have sharp edges and smooth surfaces. First class bricks are thoroughly burnt and are of red, cherry or copper colour. They are made by table moulding in the kiln. They should not absorb more than 20% water of its dry weight when immersed in freshwater for 24 hours. These types of bricks have a crushing strength of around 105 kg/cm2. These types of bricks give ringing sound when struck together. These bricks are free from flaws, cracks, stones, chips etc. and most durable. They are used for permanent and superior nature of work, and also for load bearing walls.

02. Second Class Bricks

These types of bricks have moderate quality. There are slight irregularities in the shape and size of second-class bricks. These types of bricks are moulded by ground moulding. Due to ground moulding, they don’t have sharp edges and smooth surfaces. They should not absorb more than 22% water of its dry weight when immersed in freshwater for 24 hours. These types of bricks have a crushing strength around of 70 kg/cm2. Second-class bricks also give ringing sound when struck together. These types of bricks are also used in permanent structures, for partition wall and load- bearing walls of small structures.

03. Third Class Bricks

They are of poor-quality bricks. These types of bricks are overburnt or under burnt. Third class bricks are not regular in size and shape. They have unfair edges and rough surfaces. These types of bricks are also moulded by ground moulding and burnt in clamps. They should not absorb more than 25% water of its dry weight when immersed in freshwater for 24 hours. These types of bricks have a crushing strength around 35 kg/cm2. Third class bricks give dull sound when struck together. Third-class bricks are used in temporary structures.

04. Fourth Class Bricks

Fourth class bricks are of very poor-quality bricks and brittle in nature. Hence, they cannot be used for construction purpose. They are crushed and used as aggregates in the manufacturing of brickbat concrete. They are commonly used in a broken form, in road construction, foundations and floors as coarse aggregates.

Classification of Bricks Based on Burning

05. Unburnt Bricks

They are also known as sun-dried bricks. It is believed that first-time when the bricks were used, they were in the sun-dried form (unburnt Bricks), in Egypt some 6000 years ago. Sun-dried bricks are used for temporary structures. They are not that much strong as they are dried through sunlight. These types of bricks have less fire and water resistance. Sunburnt bricks are not suitable for permanent structures. These types of bricks have very low strength as compared to other types of bricks and they are less durable.

06. Burnt Bricks

Nowadays, The bricks which are used commonly, are burnt bricks. They are prepared and burnt in a kiln. Burnt bricks have high strength as compared to unburnt bricks, still, some defects may remain. Hence, they are classified as:

- First Class Bricks

- Second Class Bricks

- Third Class Bricks

- Fourth Class Bricks

Which have already been discussed earlier.

07. Over Burnt Bricks

These types of bricks are fired at high temperature and for a longer period of time than conventional bricks. As a result, the shape of over burnt brick is distorted. Over burnt bricks are used as coarse aggregate in the concrete of slab and beam which will not come in contact with water.

Classification of Bricks Based on Manufacturing Method

08. Extruded Brick

It is manufactured by forcing clay and water into a steel die, with a very regular shape and size, then cutting the resulting column into shorter units with wires before firing. It has three or four holes constituting up to 25% volume of the brick. The holes in bricks reduce the weight of the bricks, making them cheaper and easier to use than dry pressed. The rough faces make it easier to apply finishes. Extruded common bricks are an economical type of brick that can be used for construction, where the faces are to be hidden or covered. It is used in the constructions where limited budgets are available.

09. Moulded Brick

There are two types of moulded bricks such as hand moulded bricks and machine moulded bricks. Hand moulded bricks are shaped in moulds by hand. Hand moulding of bricks is extensively used and can be made either on the table or on the ground. Machine moulded bricks are the soft irregular edges of bricks which are produced by moulding material in mould box machine.

10. Dry Pressed Brick

They are traditional types of bricks which are made by compressing clay into moulds. Dry pressed bricks have a deep frog on one bedding surface and shallow frog in another. These types of bricks are high quality bricks than an extruded brick.

Classification of Bricks Based on Raw Materials

11. Burnt Clay Bricks

It is the most used bricks. It requires plastering when used in construction works. These types of bricks are usually made from clay by burning. Burnt clay bricks are the common type of bricks for construction work. First class bricks, second class bricks, third class bricks, fourth class bricks are example of burnt clay bricks.

Also Read: Comparison of Red Bricks vs AAC Blocks vs Fly Ash Bricks vs Solid Concrete Blocks vs CLC Blocks

12. Fly Ash Bricks

As the name suggests, these types of bricks are manufactured by using fly ash. It contains a high volume of calcium oxide in it. That is why, it is usually described as self-cementing. Fly ash brick expands when coming into contact with moisture. They are less porous than burnt clay bricks. It provides a smooth surface so it doesn’t need plastering. These bricks have better properties than clay bricks and greatly resistant to freeze-thaw cycles. The advantages of fly ash bricks over clay bricks are that they have high strength, high fire insulation, uniform sizes for better joints. Being environment friendly, it is a green material.

13. Concrete Bricks

Concrete bricks or blocks are made from concrete. They are low-quality bricks and also, have low compression strength. It is the least used bricks. Concrete bricks are used above and below the damp proof course. These bricks are used for facades, fences and internal brick works because of their sound reductions and heat resistant qualities. Concrete bricks are also called mortar brick. It may be of different colours if the pigment is added during manufacturing. These types of bricks can be manufactured in sizes, as required. The advantages of concrete bricks over clay bricks are that they can be manufactured at the construction site, it reduces the quantity of mortar required, and can be manufactured to provide different colours during its production.

14. Sand-Lime Bricks

These types of bricks are made from lime and sand hence named as sand lime bricks. They are also known as calcium silicate bricks. Sand-lime bricks are used for various purpose in construction i.e. ornamental works in buildings, masonry works etc. For manufacturing sand-lime bricks, sand, fly ash and lime are mixed and moulded under pressure. During the process of wet mixing, a chemical reaction takes place, which bonds the mixtures. Then, these mixtures are placed in the moulds under pressure. The greyish colour of these bricks gives an aesthetic view. These types of bricks offer more uniform appearance and smooth finish than the burnt clay bricks, that’s why it does not require plastering. Sand-lime bricks are used as load bearing members as they are much stronger.

15. Fire Bricks/ Refractory Bricks

Fire bricks are special types of bricks which are capable of withstanding very high temperatures without affecting its shape, size and strength. They are also termed as refractory bricks. The use of refractory bricks is restricted, to the making of inner walls of furnaces for the manufacture of metals and for similar high-temperature applications. The firebricks are also classified on the basis of their reactivity towards its melting at high temperatures.

16. Acidic Bricks

They are resistant to the melts of acidic composition (but will react with the melts of basic composition). Example of these types of bricks is silica bricks.

17. Basic (alkaline) Bricks

These basic (alkaline) bricks are resistant to the melts of basic (alkaline) composition. Hence, they will not be suitable for use in those furnaces where acidic melts are being heated. Magnesia bricks and bauxite bricks are examples of basic bricks.

18. Neutral Bricks

Neutral bricks are non-reactive to both the acidic and basic melts. Hence these find applications in heating either type of melts. Examples of these types of bricks are chromite bricks and chrome-magnesite bricks.

The firebricks are further classified on the basis of their compositions

19. Fire Clay Bricks

These bricks are an important class of refractory materials of the acidic group. The raw material for its manufacturing can withstand very high temperatures without softening or fusing. Such clay is often available under the coal layers in nature. Silica and alumina are the two main constituents of fire clay. These are manufactured in a manner, similar to the common building bricks. The selected clay is crushed into the fine powder and moulded into the brick unit. These are then dried and burnt in the continuous kiln at very high temperature (1600 to 1900 centigrade). They are cooled gradually before taking out from the kiln. They are sub-divided into three types on the basis of temperature.

- High Duty. (1482 to 1648 Centigrade).

- Medium Duty (1315 to 1481 Centigrade)

- Low Duty (870 to 1314 Centigrade)

These three types of bricks have high bearing capacity and low coefficient of thermal expansion. They are generally used as a lining material in reverberatory furnaces and steel making furnaces. The refractory bricks are further classified into following types based on composition.

20. Silica Fire Bricks

These are made from mostly silica, which may range from 95 per cent or above. The remaining material is usually calcium oxide which acts as a binding agent. These are acidic in nature. Their raw materials are pure quartz (SiO2), or sandstone of high silica content. The moulded units are burnt at about 1500 Centigrade. They are extensively used in Bessemer converter as lining material because, slag in that case, is acidic in nature.

21. Magnesite Fire Bricks

They are classified among the basic refractories or fire bricks. Their raw material is magnesium oxide. The major source for it is Dolomite rocks.

22. Bauxite Fire Brick

They also form a very important class of basic (alkaline) fire bricks. They are made from the rock Bauxite which is mixed with some clay (Fire Clay type).

23. Chromite Fire Bricks

This belong to the neutral class of fire bricks. The raw material used for these type of fire bricks is a mineral called CHROMITE. The mineral is the double oxide of chromium and iron in its composition. These types of fire bricks are capable of resisting both the acidic and basic environments in a furnace. Chromite fire bricks are normally used in the steel-making furnaces.

24. Ganister Bricks

Ganister is dark-coloured sandstone containing up to 10 percent of clay. It is quarried in the UK (Sheffield being an important centre, Wales and Scotland). Their making is similar to that of silica bricks. They are very refractory, as they are capable of withstanding a temperature of 1800°C and are particularly suited for lining furnaces etc.

25. Glazed Bricks

This type of brick has a ceramic coating fused to its outer surface. These bricks are typically fired twice, once for the production of the brick itself and the second time to fuse the ceramic coating on the brick’s surface. Glazed brick is an attractive, durable option which finds use in exterior and interior constructions.

Fireclays or shales are the best for producing glazed bricks. As they are usually, required to be built with joints not exceeding 3 mm thick, they must be true to shape, with fine straight. They are, therefore carefully pressed and sometimes re-pressed, with the arrises hand-trimmed with a strike. Glazed bricks are impervious.

Advantage of Glazed Bricks:

These bricks provide an exclusive look to the constructions and increases the durability, strength and versatility. These are toughened to withstand any climatic condition and maintain their aesthetic appeal for a longer time.

Classification of Bricks Based on Usage Location

26. Facing Bricks

Facing bricks are those bricks which are visible and are fixed on the face of the wall. These types of bricks are used in facade of the building. These bricks are standard in size, stronger than other bricks and also have better durability. They provide an aesthetic view to the building or home. There are many types of facing bricks which uses different technology and techniques. Facing bricks should be weather resistant as they are generally used on the exterior wall of buildings. Extruded bricks are one type of facing bricks.

According to ‘Donald Watson’ (Author of Time-saver Standards for Building Materials and Systems), Facing bricks are classified in following three types, based on the range of variations in colour and dimensional tolerances per ASTM C216:

(a) Type FBS

These bricks are for general use where wider colour ranges and greater variations in size are permissible. These bricks are used where only average precision is required.

(b) Type FBX

These bricks are for general use where a high degree of mechanical perfection, narrow allowable colour range, and minimal variations in size are required. It is used in the specific project where a uniform, monolithic appearance is desired.

(c) Type FBX

These bricks are selected to produce characteristic architectural effects resulting from nonuniformity in size, colour and texture.

Further, the facing bricks are of different types:

(d) Fletton Brick

Fletton bricks are the most common engineering bricks in construction. These types of bricks are very hard and dense, with a pink, patchy colour. Fletton bricks tend to have a texture where bricks rest against each other in the kiln. Flettons bricks have been used throughout the UK since the start of the 20th century.

(e) Salmon Bricks

Since Salmon bricks are near the outside of the kiln during the burning process, these types of bricks are slightly under burnt. It means that they’ll be softer than the arch bricks. They are not high-quality bricks.

(f) Water-Struck Bricks

For manufacturing these types of bricks, alluvial clay with very high moisture content is pressed into moulds and water is used as a lubricant to release the wet clay from the hardwood moulds. As the clay sides out of the moulds an unusual surface finish is created, which, after firing, results in a textural patina that has never been replicated by any other brick-making process.

27. Backing Bricks

Backing bricks don’t have any special features. They are just provided behind the facing bricks to provide support.

Classification of Bricks Based on Weather Resisting Capability

According to ‘Donald Watson’ (Author of Time-saver Standards for Building Materials and Systems), bricks are classified in the following types, based on anticipated exposure to weather as per ASTM C62:

28. Severe Weather Grade Bricks (SW)

These types of bricks can withstand repeated freeze-thaw actions. They are useful for countries where severe freeze-thaw action happens.

29. Moderate Weather Grade Bricks (MW)

Moderate weather grade bricks are used in tropical countries. These types of bricks can also be useful for hot-weather countries where freeze-thaw action doesn’t happen much. They can withstand high temperature.

30. No Weather Grade Bricks (NW)

They are general bricks and they do not have any weather resisting capabilities. These types of bricks are used for inside walls.

Classification of Bricks Based on Purpose of Use

31. Common Bricks

These types of bricks are the most common bricks used in construction. They don’t have any special features or requirements. They have low resistance, low quality, low compressive strength. Common bricks are generally used for the construction of the interior walls.

32. Engineering Bricks

These bricks are popular for many reasons. Engineering bricks have high compressive strength and low water absorption capacity. They have good damp proof, load-bearing capacity and chemical resistant properties. They have a uniform red colour. They are classified as Class A, Class B, Class C. Class A bricks are the strongest but Class B bricks are most used. They are used for mainly civil engineering works like sewers, manholes, ground works, retaining walls, damp proofing courses etc. These types of bricks are burned at an extremely high temperature to form a strong and dense product. They are also used in structural designing and also used in special applications where strength, frost resistance, acid resistance, low porosity is required. Engineering bricks are generally used for basements where chemical or water attacks are prevalent.

Classification of Bricks Based on Shape

Based on shape, bricks are classified into following types:

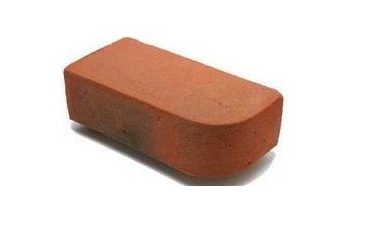

33. Bullnose Bricks

These bricks are used to form rounded quoins. Bullnose bricks, with their smooth, rounded outer edges, are used to soften the aesthetics and add protection and visual appeal on top of walls and around openings to windows, doorway or to the corner detailing of buildings.

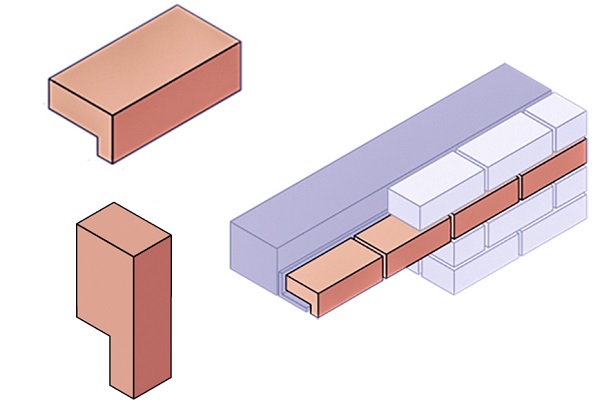

34. Coping Bricks

These bricks are manufactured in different types of shapes, to set the thickness of the wall and throated on the underside to throw away the rainwater. These bricks are used where the coping is to be provided. The shapes of coping brick can be chamfered, halfround or saddle-back. Coping bricks are used in topmost direction on parapets.

35. Cownose Bricks

Cownose bricks are manufactured with bullnose on both the ends. It is also termed as double bullnose brick. The bullnose bricks are used at the edges, where angular curved corners are recommended.

36. Paving Bricks

These bricks are specifically made for paving the surface of highways and street. These bricks are usually made from shale, fire clay or a mixture of the both. They are unaffected by ordinary traffic’s wear and weather. They are loaded on the bed of sand, which in term rests on the foundation of concrete or stone. The bricks are laid by grouting with cement mortar or asphalt. Paving bricks are machine moulded and are burnt in a continuous kiln, to ensure a high degree of vitrification.

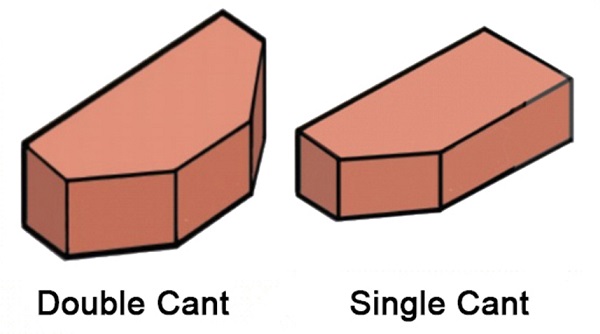

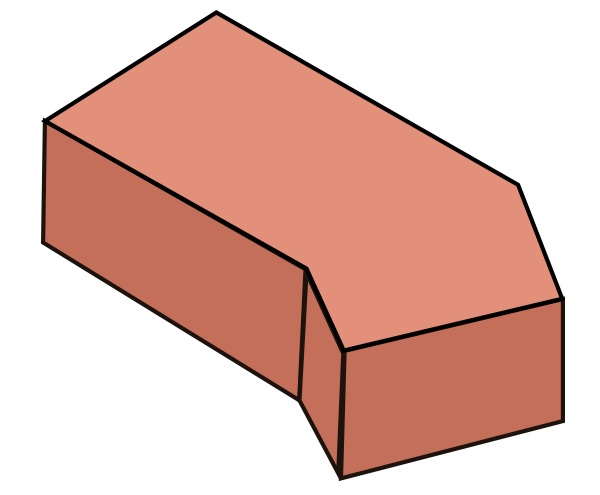

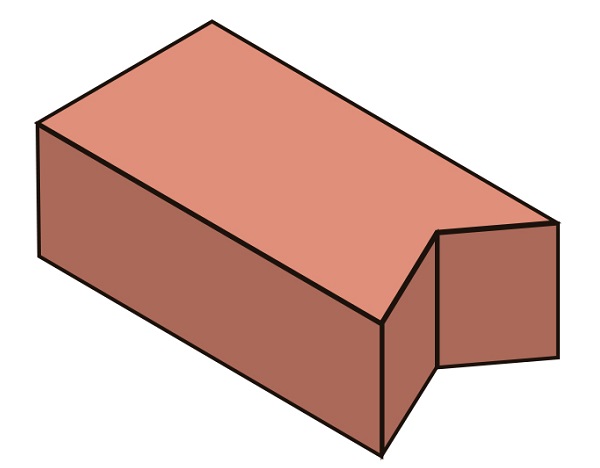

37. Cant or Splayed Bricks

These bricks have one side splayed (beveled). These bricks allow brickwork to turn through 30, 45 & 60-degree angles on a plan, with variations in leg dimensions to achieve different bond pattern requirements.

38. Arch Bricks

These bricks are made in a wedge shape to keep mortar joint in the uniform thickness. They are used to form aesthetically pleasing decorative arch units. These are used over openings such as doorways and windows to form numerous different arches.

39. Air Bricks

These types of bricks contain holes to circulate air. Air bricks are used in cavity wall and suspended floors.

40. Capping Bricks

These types of bricks contain holes to circulate air. Air bricks are used in cavity wall and suspended floors.

41. Brick Veneers

These bricks are thin as compared to other bricks and used for wall cladding.

42. Curved or Circular Bricks

Curved or circular bricks have internal and external faces curved, to meet the requirement of the particular curve and radius of the wall. These bricks are used for wells, towers etc.

43. Plinth Cornice and String Course Brick

These bricks are moulded in several patterns with the object of adding architectural beauty to the structure and at the same time helping to throw the water away from the face of the walls.

44. Dog-Leg or Angle Bricks

The dog leg brick is a specially shaped brick, which is used to turn brickwork through an angle. It does not have a rectangular shape, the edges along the narrowest side form an obtuse angle. These bricks are also termed as angle bricks or angle cut bricks. The use of dogleg brick enables to avoid the use of cut bricks and a mortar joint, where the face of the wall changes direction.

45. Birds Mouth Bricks

These are special bricks, manufactured with an indented end, designed for use in decorative brick-work and at an internal obtuse corner in a brick wall.

46. Pistol Bricks

As the name suggests, it’s shape is like a pistol as shown in the figure. These are used for forming circular or curved angles between walls or between a wall and a floor.

Classification of Bricks Based on Cavities

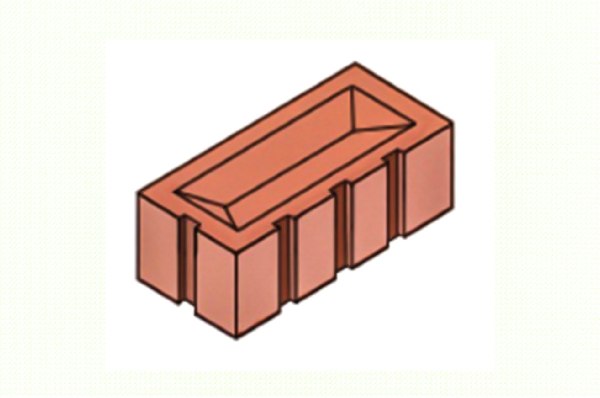

47. Hollow Bricks

Hollow bricks are made of clay and provided with one or more cavities. Hollow bricks are light in weight and are used to increase insulation against heat and dampness. They are light in weight therefore suitable for partitions.

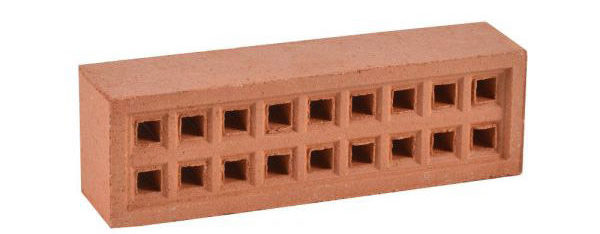

48. Perforated Bricks

These bricks are of standard size manufactured with perforations running through their thickness. Perforated bricks are easy to burn and their light- weight makes it possible to cut down the weight of the structure and effects in the foundations. The aperture of the perforations is such that, it gives the maximum amount of ventilation. But does not permit the entry of rats or mice. These bricks are used for constructing panel walls of multi storied buildings, load- bearing walls of short storied buildings and for providing partition-walls.

49. Channel or Gutter Bricks

Channel or Gutter bricks are special purpose bricks revealing a continuous central semi-circular depression or cavity running through their length. These bricks are often glazed to make them impervious. They are usually used in the laying of drains.

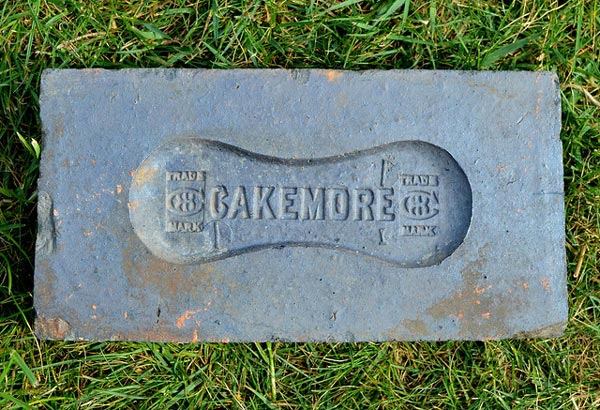

50. Keyed or Nicked Bricks

These bricks are designed to give a good key for plaster or render finishes. According to ‘W. B. McKay’ (Author of Building Construction), these types of bricks are manufactured by the London Brick Co. Ltd (https://www.forterra.co.uk/), has dovetailed grooves formed on one stretcher and one header face, to provide a mechanical bond with either plaster or roughcast, which may be applied to the brickwork.

Classification of Bricks Based on Region

51. Staffordshire Blue Bricks

These are a strong type of construction brick, originally made in Staffordshire, England. These types of bricks are made from the local red clay, Etruria marl, which when fired at a high temperature in a low-oxygen reducing atmosphere takes on a deep blue colour and attains a very hard, impervious surface with high crushing strength and low water absorption.

52. Roman Bricks

As the name suggests Roman bricks find its history back to ancient Rome. Ancient Roman bricks were made in a variety of dimensions, but were always flatter and longer than traditional bricks

53. Cream City Bricks

Cream City bricks are made from a red clay containing elevated amounts of lime and magnesia. This clay is common in regions of Wisconsin, especially near Milwaukee (USA). When the bricks are fired, they become creamy-yellow in colour. Clay found along Milwaukee’s river banks was naturally high in magnesia and lime, giving the brick its unique colour and durability.

54. London Stock Bricks

These types of bricks are the handmade bricks which were used for most of the building work in London and South East England. Its characteristic yellow colour and soft appearance come from the yellow local clay from which the bricks were made.

55. Dutch Bricks

Dutch bricks are a small type of yellow brick made in the Netherlands. These types of bricks are made from compressed and stabilized earth.

56. Nanak Shahi Bricks

These bricks are from India. They were decorative bricks used for structural walls during the Mughal era.

Summing up, bricks have been in use for thousands of years from the earliest civilizations to the most recent buildings. Simply put, it lasts! Bricks are made from clay or shale and fired in a kiln at approximately 2000 degrees Fahrenheit to fuse the particles together. It continues to be used throughout the world because it looks great in both traditional or contemporary architecture, is readily available in all colours, textures and sizes. It won’t burn and requires minimal maintenance.

Building a house exclusively of Bricks can be costly, but it’s a sensible investment that pays off. Interior walls made of bricks help to adjust the building’s temperature, as they store heat and cool air. In winter, the walls offer warmth, while on a hot summer day they have a cooling effect. This creates a pleasant indoor climate, which means a healthy house. Different types of bricks are used at different places based on local availability.

Must Read:

Stone Masonry Construction: 40+ Various Guidelines to Keep in Mind!

Types of Lintels | Their Uses in House Construction

Various Types of Footings for Your House

Image Courtesy: Image 10, Image 13, Image 14, Image 15, Image 17, Image 19, Image 21, Image 22, Image 23, Image 24, Image 30, Image 31, Image 34, Image 35