Cavity in a construction? Don’t you find it alarming enough? Actually yes, cavity in a construction wall can be disastrous indeed, but when it is about having a cavity wall, it’s something special. In fact, it is an architectural splendor that can add some specific advantage to a building. The use of cavity wall was once considered a trend especially in mediaeval age, howsoever, modern construction has explored it as a trend setter for a building. Adding cavity walls in a building will have many impacts even at the age of 22nd century.

Here in this article, we are going to learn the purpose of cavity wall, its advantages, disadvantages, and the nitty-gritty about its construction.

History of Cavity Wall

According to ‘R. Barry’ (Author of The Construction of Building), cavity wall became quite common a feature for external walls of almost all small buildings. The trend was mostly seen in the constructional anatomy between 1920 and 1940. It was constructed as the cavity walls with an outer leaf of bricks or blocks, a consistent hollow space intermediate, and an inner leaf of bricks or blocks.

Cavity walls were common in Greek and Roman times, but later were developed as a component of contemporary construction in the 18th and 19th centuries. Even during this time, construction of cavity walls was rare, and generally involved two leaves of masonry bonded by headers spanning across the cavity. The use of metal ties to connect the two layers only emerged in the second half of the 19th century. The trend became more common in use toward the beginning of the 20th century.

Purpose of Cavity Wall

The cavity walls are constructed for the following purposes:

01. Damp Prevention

Cavity walls reduces the chance of moisture intrusion from outer leaf to the inner leaf and thus helps in keeping inside of the building free from dampness.

02. Thermal Insulation

The air in the cavity wall acts as a non-conductor of heat and hence minimizes the transmission of heat from the outer leaf to the internal face of the interior leaf. Thus, cavity walls help in maintaining the thermal insulation of a premise.

03. Sound Insulation

The air in the cavity acts as a cushion for absorbing sound. By building cavity walls, a premise may work as a sound proof zone as a large quantity of external noise gets absorbed within the cavity.

04. Efflorescence Prevention

As dampness is not allowed to penetrate the cavity, the inner leaf of the cavity, which is always a load bearing wall, is kept free from efflorescence effects.

05. Economy

According to ‘W. B. McKay’ (Author of Building Construction), building a 275 mm cavity wall costs less than constructing a 328 mm solid wall (which is of the minimum thickness if dampness has to be mostly avoided). This measuring data may vary from one place to another and on the specific climate of the construction site. One has to calculate the customized details before deciding the measurement of a cavity wall.

What is a Cavity Wall?

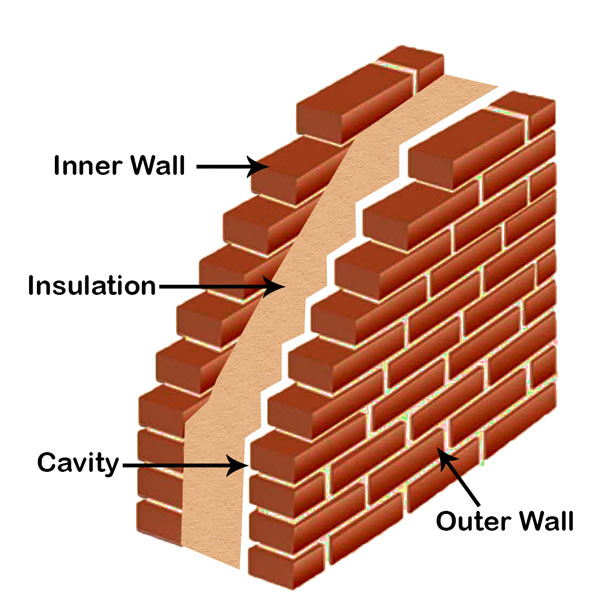

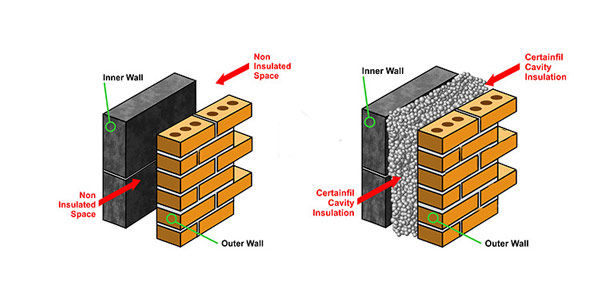

According to the ‘National Building Code of India’ (1983), “A wall comprising two leaves, each leaf being built of masonry units and separated by a cavity and tied together with metal ties or bonding units is called a cavity wall”. The structure is made in a way that the two leaves behave as one structural unit, and the space between the leaves is either kept as a continuous cavity or it is filled with waterproofing material or a non-load bearing insulating material. Ideally, the thickness of each leaf of a cavity wall shall not be less than 7.5 cm.

A cavity wall consists of two parallel walls with a 5 cm to 8 cm gap or a cavity between them. It is also known as a hollow wall but sometimes, this cavity may be filled with insulation material. The outer wall also known as an outer leaf, consists of a 10 cm (half brick) thick wall and the inner wall is sufficiently thick and strong to carry the imposed load safely if it is load bearing structure. The minimum thickness of the inner wall or inner leaf is restricted up to 10 cm. The provision of a continuous cavity in the wall efficiently restricts the spreading of dampness to the inner wall. Cavity walls are used to construct the outer wall of a house.

The outer leaf is essentially built with a decorative face, generally made of brick. It helps to keep the rainwater out, at the same time also adds to the wind load resistance of the entire wall. To make sure that the entire wall structure is stable, the brick outer leaf is kept “tied” to the inner leaf with the use of wall ties. These are plastic or metal ties that are permanently fixed into the mortar of both block and brick.

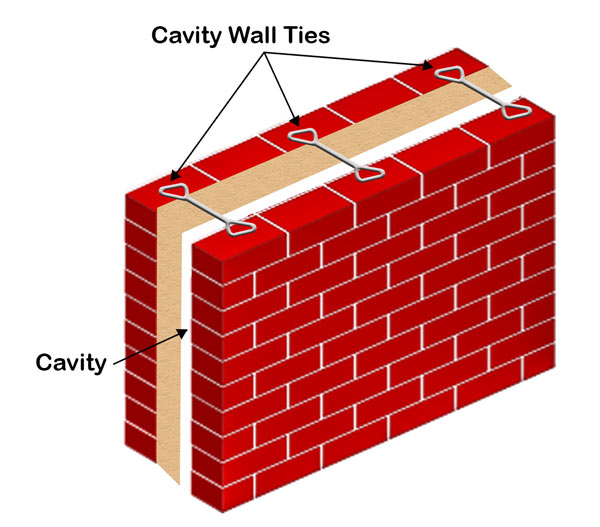

Wall Ties

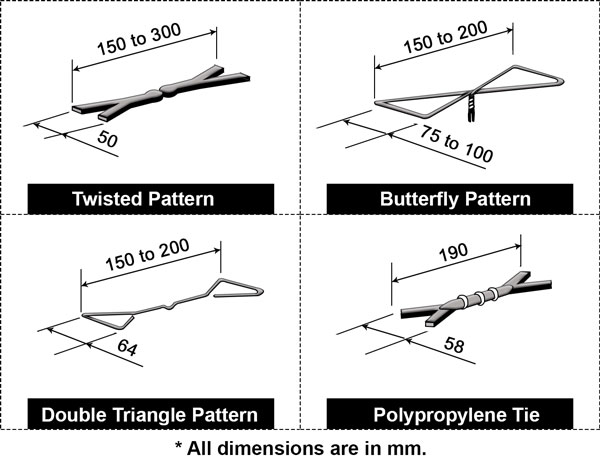

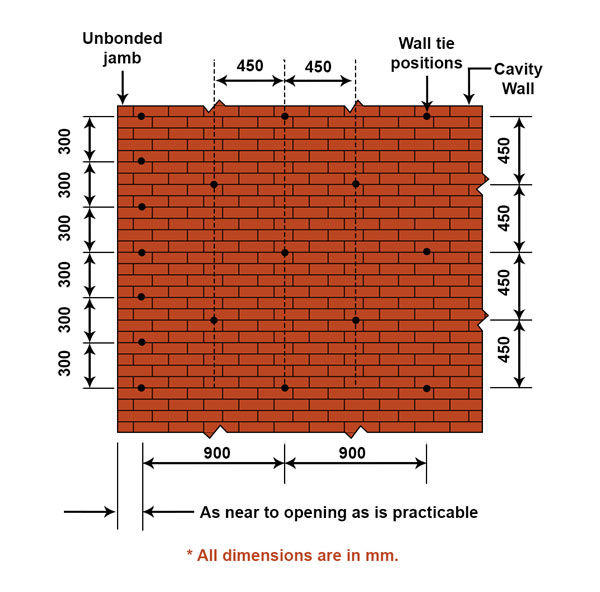

The two walls are tied together with the metallic or some terra-cotta ties to achieve structural stability. The wall ties are spaced 90 cm apart horizontally and 30 to 45 cm apart vertically in staggered positions to ensure the best stability.

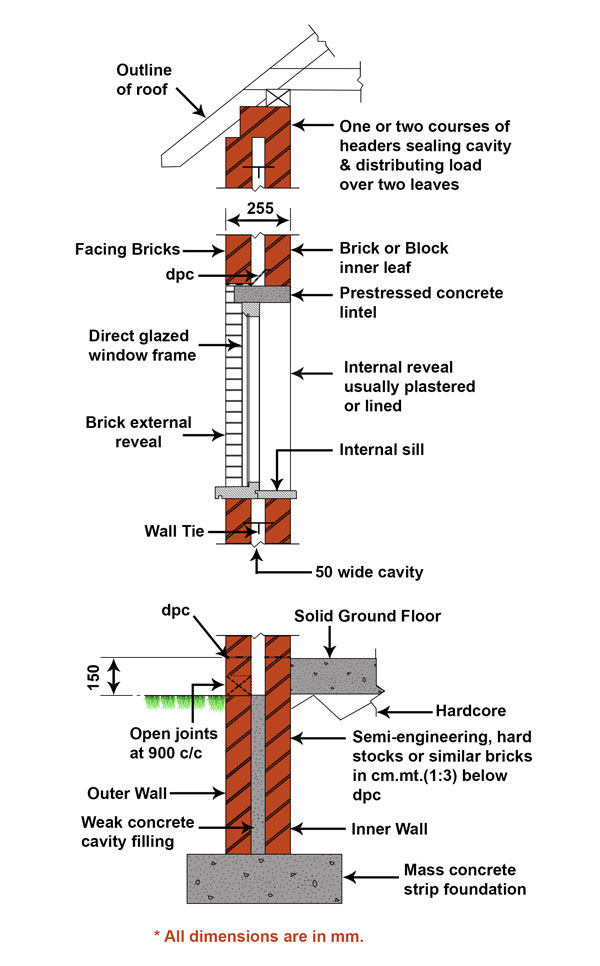

Position of Cavity

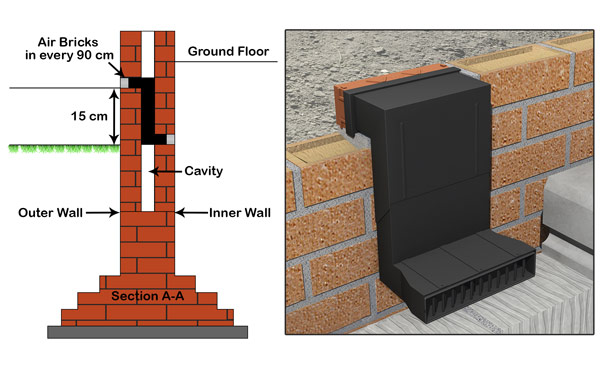

The cavity should start from the ground level and ideally should get terminated near eaves level in case there is a sloping/pitched roof or near coping in case of a flat roof with the parapet wall. The cavity should rather start 15 cm below the damp-proof course level. This has the advantage of draining of any condensed moisture below the level of the damp-proof course.

Likewise, to prevent infiltration of moisture, the bottom of the cavity should lie at least 15cm above the outside ground level. The damp-proof course for the outer and inner leaves is laid separately although the same level is ensured. This is vital to continue the cavity below the damp-proof course. The cavity is kept fully ventilated by providing air bricks in the external wall immediately above the damp-prof course. The air bricks should be placed 90 cm apart. Similarly, air bricks are provided near the top of the cavity.

Construction of a Cavity Wall

(a) Cavity Wall at The Door or Window Openings

The constructional treatment of the cavity wall at the door or window openings requires some special arrangement. Since the object of the cavity is to separate the two leaves, the placement of a vertical damp-proof course is essential to seal the cavity at the window and the door point.

The openings of doors and windows can provide an easy access to the dampness to pass into the cavity. At the sill level, it is always advantageous to keep the back of the sill flush with the back face of the external wall. In case of wooden sills, a horizontal damp-proof course is a better choice, which ideally should be made of a flexible construction suitable material.

At the top of openings of doors and windows, stone or brick arch or concrete lintel is built to carry the loads from the structure above the opening. In order to distribute the load evenly, the cavity may lay continuous, the two walls should have the separate lintels or arches. Sometimes a common lintel is provided for both the leaves.

In such a case, an inclined strip of lead or any other flexible damp-proof course membrane is provided to bridge over the cavity. The damp-proof course should extend lengthwise beyond the frame for a distance of about 15 cm on either side. This treatment helps in draining condensed moisture if any beyond the sides of the frame.

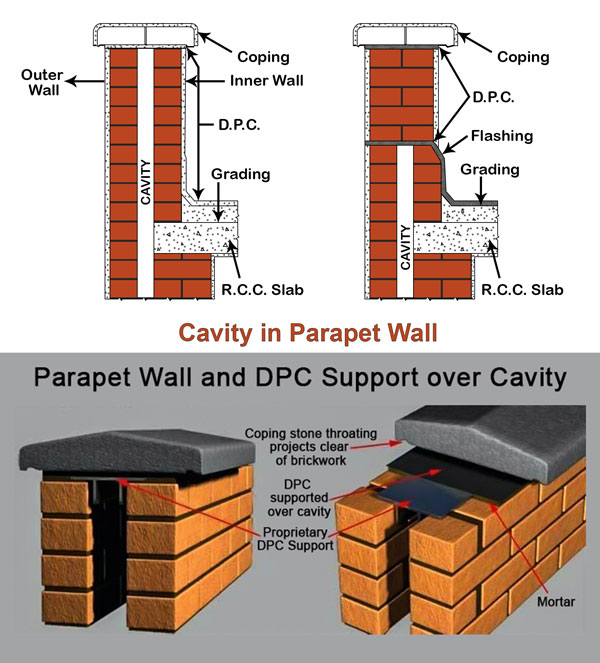

(b) Cavity Wall in Roof

In case of a flat roof, the cavity is made continuous for the full height of the parapet wall and is sealed by the coping. In case of inclined roofs/pitched roofs, the cavity is made closed at eaves level. It is important to take special precautions so that no mortar fall inside the cavity during the process of construction.

For this purpose, a wooden batten of adequate length and having a width equal to that of the cavity is used. The batten is supported over the wall ties and construction of brick masonry wall is carried out (on either side of the batten) to the height where next row of wall ties has to be provided. By this method, the cavity remains clean of mortar droppings.

(c) Cavity Wall in Parapet Wall

If the cavity has to be continued up to the coping level, the layer of damp-proof course should be laid continuous covering the full thickness of the wall immediately below the coping. Damp-proof course layer is laid alongside the full thickness of the wall at a level where the cavity joins the solid wall.

Exposure of the two faces of a solid parapet wall may develop cracks due to the temperature variations or on account of bad workmanship which may allow dampness to intrude inside. By constructing two separate wall thickness, the risk of moisture and damp infestation can be successfully reduced/stopped.

Each wall thickness is exposed to the weather on one side and protected/covered on the other side. In heavy rainfall areas, when the damp resistance capacity of the outer wall material exceeds, the rainwater may find its way into the cavity and gets harmlessly drained off at suitable points. Thus, the cavity system of construction works useful for the parapet walls.

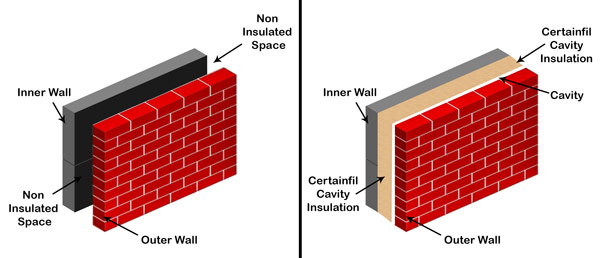

Types of Cavity Wall Insulation

Most common types of cavity wall insulation materials are:

01. Mineral Wool or Rockwool

Mineral Wool or Rockwool is the cavity wall insulation material used commonly for insulation in residential buildings. It is made from an igneous rock which is heated and spun to create fiber material. This is blown into the cavity wall which then occupies the space between the exterior and interior walls of the building. The material is water resistant and it can prevent moisture intrusion caused by rain, which usually gets through the outer leaf of the wall to reach the inside leaf of the building.

02. Polystyrene Bead

Expanded Polystyrene Beads or EPS beads are utilized in the cavity of cavity walls. These are pushed into the cavity of the walls, which is mixed with an adhesive to hold the beads together in order to avoid the risk of spilling of the same outside of the wall. This type of insulation is generally used in narrower cavity walls. It is a preferred insulation material rather than using mineral wool insulation. Polystyrene Bead insulation is also preferred in some stone-built houses.

03. Cavity Foam Insulation

Urea formaldehyde foam was normally used for the insulation of cavity walls. This insulation material usually has the benefit of insertion: the insertion of insulation material is done via smaller holes which are to be drilled in the walls or on the brickwork. However, it is not a popular option presently. Most people use Polyurethane foam both as cavity wall insulation material and a material to stabilize the wall structure where the wall ties have been futile, as an option to replace the wall tie itself. However, where work is done purely for thermal insulation effect only, either polystyrene beads or mineral wool are the most preferred ones.

Advantages of Cavity Wall

The advantages of cavity walls are,

- As there is no direct contact between the two leaves except at the wall ties (which are impervious material), there is hardly any possibility of the moisture intrusion from the outer leaf to the inner leaf. According to ‘R. Chudley’ (Author of Construction Technology Vol-1), cavity walls can withstand a driving rain in all situations from penetrating to the inner wall surface.

- The layer of air in the cavity being non-conductor of heat reduces the transmission of heat from the external face to the internal one and as such cavity walls are the best suitable for temperature control in room in a tropical country like India. Cavity walls gives good thermal insulation keeping a premise warm in winter and cool in summer.

- They offer a good sound insulation property. A nominal 255 mm cavity wall has a higher sound insulation value than a standard thick brick wall. As a result they can reduce the effect of external sound.

- Cavity walls are fire-resistant.

- Cavity wall can reduce the risk of moisture condensation.

- The wall can reduce the cooling cost of the building.

- It gives protection against efflorescence.

Disadvantages of Cavity Wall

- Highly skilled masons, labors, as well as expert designers and implementing workmanship are the basic requirement for the construction of a well-built cavity walls.

- Cavity wall construction requires good supervision during its construction phase.

- It requires installation of a vertical damp-proof course to all openings.

- There is always a risk that moisture may get its way to the inside, whatever is the insulation material.

- It decreases carpet area efficiency.

- Saturation and settlement of cavity-fill lead to cold bridging or thermal bridging. (Thermal bridging is the process of the movement of heat across an object that is more conductive than the materials around it.)

- There is also the possibility that the installation will leave unfilled air pockets –causing ‘cold spots’ on the inside walls which will attract condensation.

- Another problem is wall-tie corrosion; cavity insulation makes the outer brick leaf colder, and therefore wetter. The condition can speed up the rusting of the wall ties. Alternatively, if the ties have to be replaced, there is no satisfactory way of refilling the holes further in the insulation, whatever was the insulation material.

- The thickness of insulation is restricted by the width of the cavity.

- There is a significant number of buildings with mortar droppings on ties within the cavity which results in penetrating dampness.

Conclusion

From the above discussion, we may safely conclude that you can control moisture intrusion in your home by the construction of the cavity wall as an exterior wall of your house. Cavity wall also provides thermal as well as sound insulation benefits.

However, building cavity wall requires skilled labor and good supervision during the construction. If you can construct it in the right manner, it will be highly beneficial for you and your home in terms of comfort and maintenance.

Must Read:

PVC Wall Panels | Types & its Pros & Cons

Home Interior | Wall Panelling | Types of Wall Panelling

Aluminium Composite Panels: All the Basic Information you Need To Know!

Image Courtesy – Image 9