The property of fresh concrete is workability and it gives the procedures about how the work can be done effortlessly using the fresh concrete. Thus, workability of concrete signifies that you can be able to carry out all the concreting procedures like Mixing, placing, compacting and finishing smoothly without any isolation and flow.

In order to evaluate the workability of concrete there are a variety of tests which are existing like the slump test, flow test, factor test, vee bee test and the Kelly Ball test etc. Let us discuss here the Kelly Ball test of concrete what are its methods, its testing apparatus and the outcome etc.

What is the Kelly Ball Test of Concrete?

The Kelly ball test is a test that measure workability of fresh concrete on the construction site. The Kelly ball test method has been developed as a fast alternative to the slump test which is effortless and reasonably priced. This type of test can be executed rapidly and the end result s can then be correlated to slump.

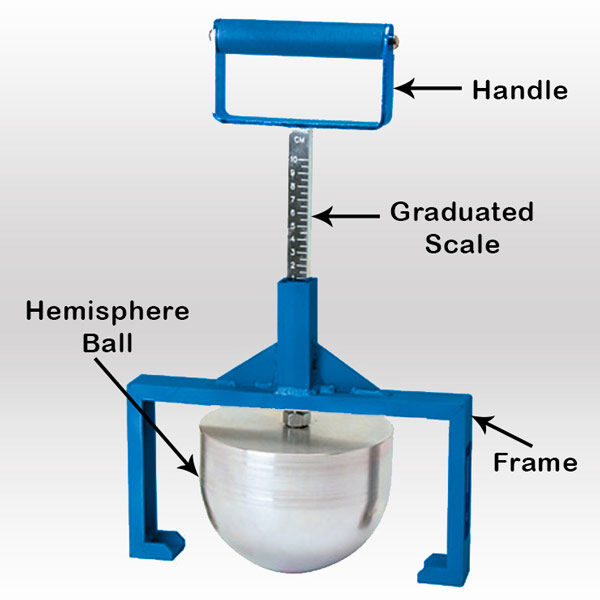

The workability of concrete in the Kelly ball test, is decided by the depth of the penetration of metal hemisphere (ball) which will descend under its own weight into the fresh concrete. The Metal hemisphere or ball has 152 mm diameter and 13.6 kg weight. J. W. Kelly (Professor, University of California) had devised the plan of the Kelly ball test apparatus. Hence, later on it also came to be known as a ball penetration test.

Advantages of the Kelly Ball Test

- The ball penetration test there is no need for filling, rodding a container or basically there is no need to use any set up as it is much faster than the slump test.

- To obtain a straight and immediate outcome, Kelly ball test can be performed on the fresh concrete in the field-in-place or in form, buggy, wheelbarrow, or hopper.

- We can get more precise and accurate outcomes in ball penetration test than the slump test.

- To find the workability of concrete or infer or understand the test results, this workability test does not require any lengthy calculations.

Disadvantages of the Ball Penetration Test

- When the ball penetration test is performed, the surface of the concrete must be levelled.

- As per the ‘A. M. Neville’, (honorary member of the American Concrete Institute; author of Properties of Concrete), the workability test is an American one and rarely used somewhere else.

- Concrete with large size of aggregate can’t be used in the ball penetration test because it can influence the results.

- Indian standards don’t recognize and don’t use the Kelly ball test.

Standard Guidelines for the Ball Penetration Test

- ASTM C360-92

Kelly Ball Test Apparatus

- Metal hemisphere (Ball): This is the most important constituent of Kelly ball test apparatus and it has 152 mm Diameter and 13.6 kg weight

- Graduated Scale: The reading of penetration of hemisphere (ball) is shown by the graduated scale.

- Handle

- Frame

Kelly Ball Test Procedure

01. The concrete which is presumed to be tested should be poured into a container such as a buggy or actually in the form which should be up to a depth of 200mm (20cm). Then once the concrete is poured the top surface should be leveled.

02. On the surface of the concrete the Kelly ball apparatus should be placed. The handles of the hemisphere (ball) should be placed in such a way that the frame touches the surface of the concrete. Away from the containers end the minimum lateral dimension of frame should be around 230 mm (23 cm).

03. Then once it is done, the handle should be released slowly and the ball should be allowed to penetrate through the concrete by its own weight.

04. Once the ball (hemisphere) is relieved, the penetration depth of the ball will be signified on the scale.

05. Then the reading of the graduated scale should be noted down. (In which the penetration is showed).

06. The same procedure should be repeated at different portions for at least three times in the container and the then the average values of these readings should be taken down.

Points to be Taken Care Of

- At the middle portion of the container the Kelly ball apparatus should be placed. The concrete should be poured up to the depth of 200mm (20 cm) and the lateral dimension should be at least 460 mm (46 cm) when the concrete is being poured in the container to avoid the effects of the boundary.

- The concrete should be leveled appropriately at the surface.

Hence, we can summarize that for the regular checking of workability for the quality control purpose, the Kelly ball test is similar to the slump test and is very effortless to perform on the field. The ball penetration test is economical and faster to execute than the slump test.

As listed above the workability of concrete can be measured with diverse techniques. To know more about how to perform other tests, then kindly check our blogs on slump test, compaction factor test, flow test, and vee bee test.

Also Read:

Cube Test to Check the Compressive Strength of Concrete

Ultrasonic Testing Procedure For Concrete Structure

In-Situ Concrete Pull Out Test for Compressive Strength

Penetration Resistance Test for Concrete Compressive Strength

Image Courtesy: Image 1