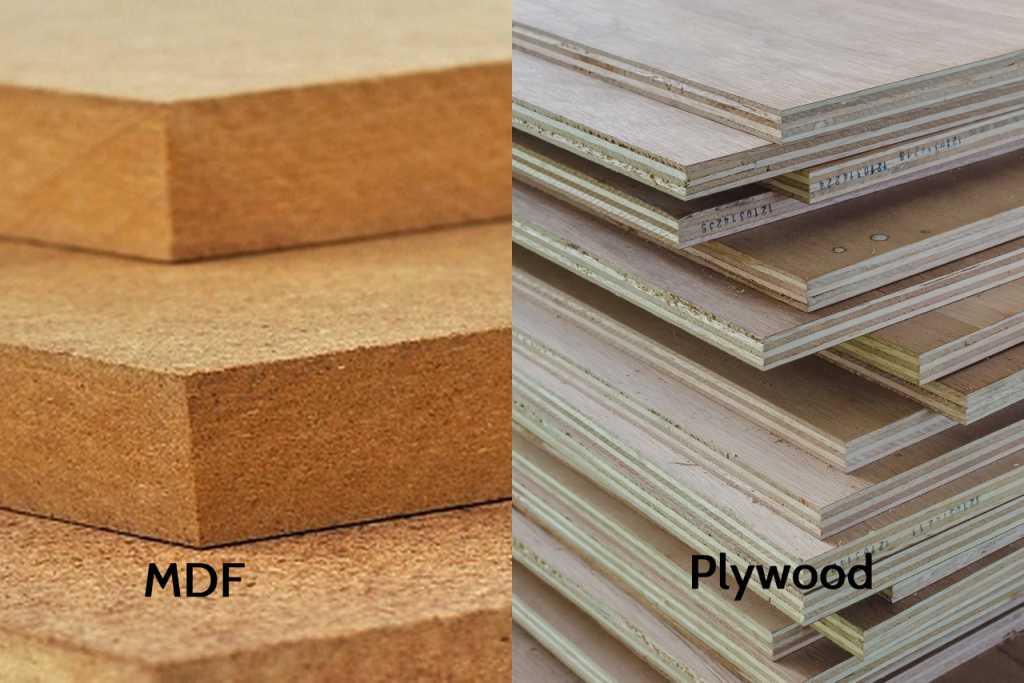

There are different types of engineered wood available in the market like plywood, MDF, hardboard, particle board, block board, etc. Plywood and MDF are both engineered wood products popularly used for home décor and furniture making. When we compare MDF vs plywood, both have their own pros and cons. These products have their own set of distinctive properties which makes them very diverse from one another. Hence, here we have tried to give you a brief comparison of MDF vs plywood to help you make the correct choice.

01. Material

- Medium Density Fiberboard is an engineered wood composite made by mixing the wood fibres with wax and resin binders and made into sheets by applying high temperature and pressure.

- Plywood is a wooden panel; made by stacking several thin layers of wood veneers over each other.

02. Uses

- MDF is mostly used for making ready-made furniture, cabinets, and shelves in storage units.

- They are extensively used in decorative wall cladding and embossed jalis.

- Transparent partitions are also made by carving MDF board sheets to give contemporary or traditional look.

- Most commonly used for making custom built furniture for home and offices.

- It is also used in building construction in the form of concrete shuttering panels, floors, walls and roofs.

- BWR grade plywood is used in making kitchen cabinets and other kitchen furniture.

- Marine plywood is used for making boats and ships.

03. Properties

(a) Resistance To Physical Components

01. Water

- MDF soaks water like a sponge and begins to degrade into small pieces.

- Plywood has more resistance to wards water.

02. Impact

- Its impact resistance is lower as compared to that of plywood.

- It has the ability to withstand short term overload.

03. Warping and Cracking

- MDF can be easily split and damaged.

- Due to its cross-laminated structure, plywood has more resistance to warping and cracking.

(b) Appearance

- As it is consistent throughout the edges. MDF has smooth and uniform surface and wood grains are not visible.

- The layers of wood veneers are visible from the edges. It often splinters on the edges.

(c) Weight

- MDF is light in weight when compared with plywood.

- It is comparatively heavier than MDF.

(d) Cutting

- MDF can be easily cut and offers smooth surface after cutting.

- Plywood should be cut carefully as it will splinter on the edges.

(e) Fitting

- MDF does not hold screws well as it is made up of very fine fibers.

- Plywood can hold screws very well.

(f) Surface Finishing

- MDF can be easily laminated, veneered or lacquered. It is not preferred to paint MDF, as it absorbs the paint. If MDF is painted using duco paint, it will be more expensive than plywood.

- Plywood can be easily painted, laminated, veneered or lacquered.

(g) Toxicity

- Formaldehyde resins are used to bind MDF making it toxic.

- Plywood is emits VOC’s but it is also available in low or no VOC’s emission grade.

(h) Strength and Durability

- When compared with plywood, MDF has less strength and durability.

- It has high strength as well as durability owning to its cross laminated structure.

Also Read: Properties of Plywood as a Building Material

04. Size

- Standard MDF are available in a range of sizes, the most common sheet sizes are

(1) 8 x 4 feet (2449 x 1219 mm)

(2) 12 x 4 feet (3658 x 1212 mm)

- Available in a range of thickness from 8 mm to 25 mm*Note: Customized sizes are available depending on different thickness

The most commonly manufactured and sold plywood size in India is 8×4 ft. (2449 x 1219 mm)

Its thickness varies from 3 mm to 25 mm.

*Note: Customized sizes are available depending on different thickness

Also Read: What is the Size & Cost of Plywood?

05. Life

- It has 1\4th life span as that of furniture made from real wood. In dry environment, they last up to 10 years. For laminated MDF, it is difficult to repair after de-lamination starts, thus have to be replaced after 15-20 years.

- Plywood has a life span of 30years and can last more, if it is laminated or veneered.

06. Cost

- It is very cheap as compared to Plywood.

- It is expensive when compared with MDF.

Special Comments

Depending upon the application area and budget, MDF and plywood should be selected. For custom made furniture which supports heavy loads and for kitchen cabinets, plywood is recommended. MDF is better for bedrooms where a load is less.

From the above comparison of MDF vs plywood, the user needs to make a judicious and rational choice depending upon the budget.

The Popular Manufacturers of Plywood and MDF in India are:

Also Read:

Different Grades of Plywood

Advantages and Disadvantages of Plywood

Things to Keep in Mind while Buying Plywood