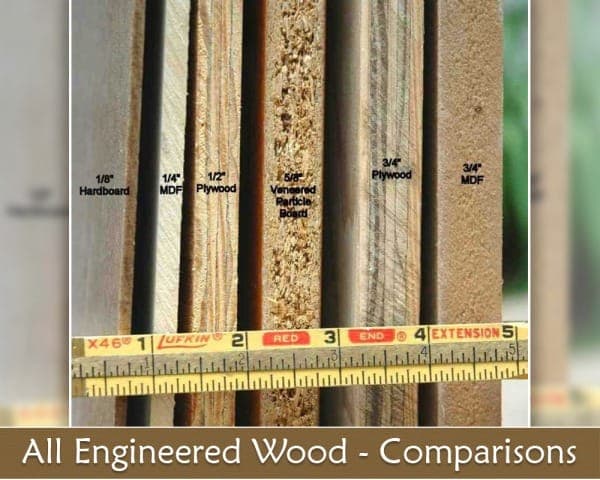

There are different types of engineered woods available in the market like plywood, MDF, hardboard or HDF wood, particle board, blockboard, and others, which are extensively preferred over solid wood or natural wood for making furniture. Most manufacturers claim that all products are suitable for a variety of purposes similar in nature. This can make it tough for homeowners to choose the most suitable material for their home building or refurbishment projects.

Each of these products are made using different raw materials and manufacturing process. Naturally, they have their own set of distinctive properties and applications, making it important to know where to use what. You cannot just randomly use any engineered wood or plywood for any element.

In this post, we have compared the different types of composite wood and solid wood based on four parameters, namely strength, uses, life, and cost. At the end of the post, you will get a fair idea of the following,

- Various types of engineered wood

- HDF Vs MDF,

- Natural wood vs plywood

- Solid wood advantages and disadvantages, and

- High-density fiberboard advantages and disadvantages

Let’s look at Solid Wood vs Plywood vs Blockboard vs HDF vs MDF vs Particle Board differences.

01. Strength

Solid Wood

- Depending upon the species of wood, solid wood is the strongest as compared to all engineered woods.

Plywood

- Due to its cross-laminated structure, plywood is strongest amongst all engineered woods. It is also stronger in comparison to many softwood of inferior species of natural wood.

Blockboard

- As the blockboard is made of softwood strips, it has less strength as compared to plywood but is stronger than other fiberboards.

HDF

- HDF board is the strongest among all the fiberboards.

MDF

- When we compare MDF vs HDF, the former has lesser strength. However, MDF is definitely stronger than particle board.

Particle Board

- Particle Board is the weakest form of all the engineered board types.

02. Uses

Solid Wood

- Solid wood has been used for centuries to make wooden frames.

- It is also used to make durable indoor and outdoor furniture.

- Several builders use them to make door and window frames, masts and spars for ships, aircraft, crates, boxes, ladders, and in general millwork.

Plywood

- Most commonly used for making custom-built furniture for home and offices.

- It is also used in building construction in the form of concrete shuttering panels, floors, walls, and roofs.

- BWR-grade plywood is used in making kitchen cabinets and other kitchen furniture.

- Marine plywood is used for making boats and ships.

Blockboard

- It is the most preferred choice when long pieces of wood are required for furniture-making as it is stiffer and does not bends or sag like plywood. So, it can be used for making long bookshelves, tables, benches, extended wall panels, exterior and interior doors, and shutters among others.

HDF

- HDF board is preferred for furniture where heavy traffic is expected, such as in hotels, cinemas, libraries, and government offices.

- It is also available in the perforated form. This type of HDF is used for hanging various tools of the workshops.

- As HDF wood is highly resistant to moisture, it is used as a core material for laminate flooring.

MDF

- It is mostly used for making furniture, cabinets, and shelves in storage units. They are extensively used in decorative wall cladding and embossed jalis.

- Transparent partitions are also made by carving MDF board sheets, giving a contemporary or traditional look to the home or workplace decor.

Particle Board

- It is used for making lightweight furniture such as shoe racks, accent pieces, and portable furniture where heavy loads are not applied or expected.

- It is also preferred for modular office furniture, kids’ room furniture, computer tables, and wardrobes placed in areas where there’s minimum contact with moisture.

- It can be used as shutters for various storage units, as laminated particle boards.

- It is also used as under lament, flooring, wall paneling, and partitioning.

03. Life

Solid Wood

- Solid Wood is known to last for centuries as it can be sanded several times during its lifetime.

Plywood

- Plywood if laminated or veneered, can last for over 50 years. In a dry environment, its life can be increased by a few more years.

Blockboard

- Blockboard has less durability than plywood as softwood strips are used when manufacturing it.

HDF

- HDF wood is quite durable. It can last many years without getting damaged.

MDF

- In a dry environment, they last up to 10 years. Laminated MDF can last for 15-20 years; however, it needs to be replaced after this period.

Particle Board

- Particle boards generally last for 5 years. However, if their surface is laminated they can last even for 10 to 15 years.

04. Cost

Solid Wood

- Being a natural material, solid wood is scarce. Therefore, it’s more expensive in comparison to engineered wood.

Plywood

- Among all types of engineered wood, plywood is the most expensive, as it is made from several wood veneers.

Blockboard

- As blockboard uses strips of softwood, it is costlier than the HDF board but cheaper than plywood.

HDF

- HDF is expensive in comparison to MDF as more pressure is applied during the manufacturing process.

MDF

- MDF is cheaper than HDF wood, but expensive in comparison to particle board.

Particle Board

- Particle Board is the cheapest type of engineered wood.

The popular manufacturers of engineered wood or composite wood are as follows:

Must Read:

Different Grades of Plywood

Properties of Plywood as a Building Material

Advantages and Disadvantages of Blockboard

7 Uses of Particle Board in Building Industry

Image Courtesy: Image 1