There are different types of engineered woods available in the market like plywood, MDF, hardboard, particle board, blockboard, etc. They all have different properties, applications, raw materials as well as manufacturing process. These products have their own set of distinctive properties which makes them very diverse from one another, and hence one has to use them judiciously and not randomly.

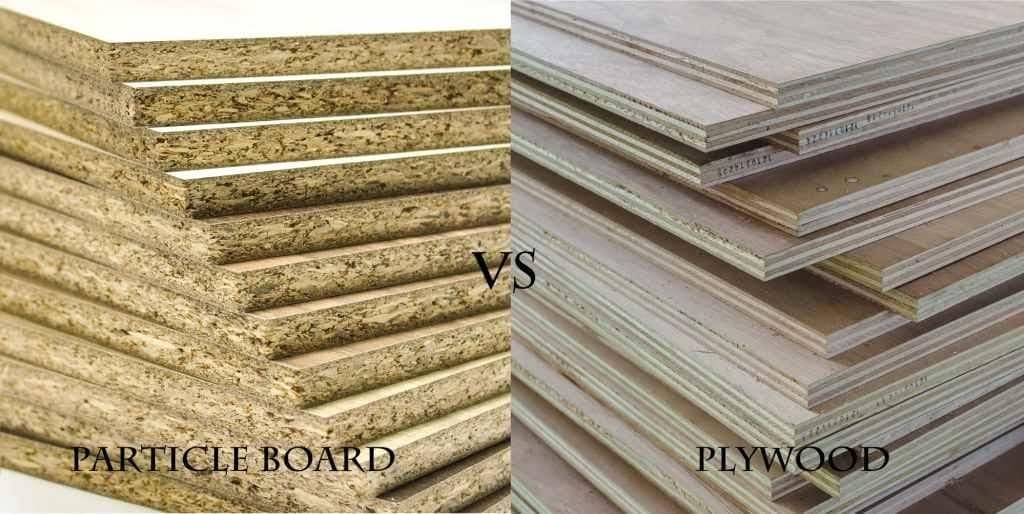

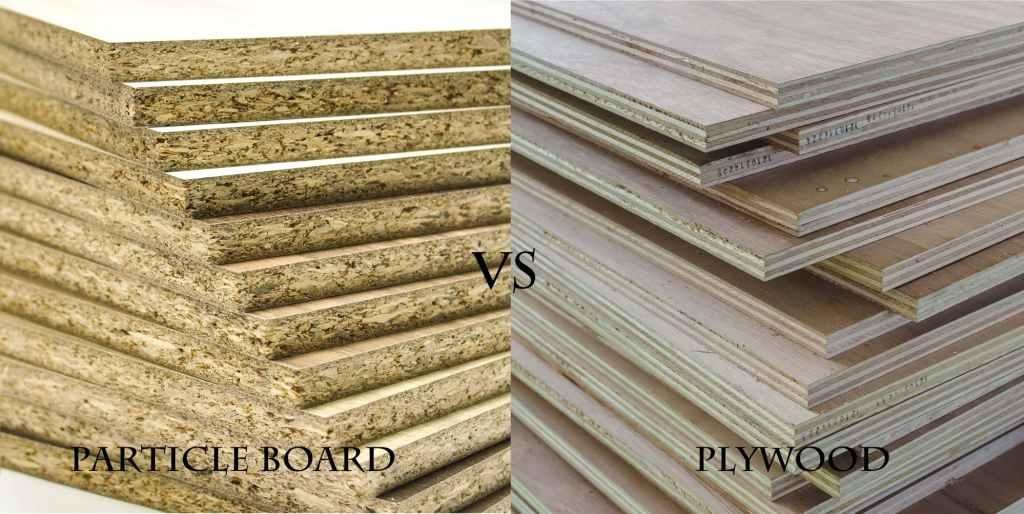

When we compare particle board vs plywood, there arises confusion as they both are recommended for uses like to make furniture for home. Hence, here we have tried to give you a brief comparison of particle board vs plywood to help you make the correct choice.

Courtesy - Shuterstock

Particle Board vs Plywood

PARTICLE BOARD | PLYWOOD |

01. Material | |

|---|---|

| 01. Particle board is an engineered wood product made from waste products like wood chips, sawdust, and wood shavings. | 01. Plywood is a wooden panel; made by stacking several thin layers of wood veneers over each other, i.e. better raw materials. |

02. Uses | |

|---|---|

| 01. It is used in light weight furniture such as shoe racks, accent pieces, portable furniture, etc. where heavy loads are not applied. 02. For people who shift home frequently due to job circumstances, particle board furniture is more preferred as they can be easily transported. 03. It is used in modular office furniture, children furniture, and wardrobes in areas where they are not in contact with moisture. By laminating them, their durability can be increased. 04. It can be used as shutters for various storage units, as laminated particle boards. 05. It is also used as underlayment, flooring, wall paneling, and partitioning.

Also Read: 7 Uses of Particle Board in Building Industry | 01. Most commonly used for making custom built furniture for home and offices. 02. It is also used in building construction in the form of concrete shuttering panels, floors, walls and roofs. 03. Plywood is also used in making fences and signs for outdoor advertising, etc. 04. BWR grade plywood is used in making kitchen cabinets and other kitchen furniture. 05. Marine plywood is used for making boats and ships.

Also Read: Different Grades of Plywood |

03. Properties | |

|---|---|

(a) Appearance | |

|

|

(b) Resistance to Water | |

|

|

(c) Resistance to Warping and Cracking | |

|

|

(d) Weight | |

|

|

(e) Load Carrying Capacity | |

|

|

(f) Fitting | |

|

|

(g) Surface Finishing | |

|

|

(h) Toxicity | |

|

|

(i) Strength and Durability | |

Also Read: Particle Board: Properties You Need To Know! |

Also Read: Properties of Plywood as a Building Material |

04. Size | |

|---|---|

| 01. The most commonly manufactured size of particle board in India is 8 feet x 4 feet. (2449 x 1219 mm) Particle board is available in range of thickness from 9 mm to 25mm. | 01. Plywood is generally available in a common sheet size of 8 feet x 4 feet (2449 x 1219 mm) Available in a range of thickness from 3 mm to 25mm. *Note: Customized sizes are available depending on different thickness

Also Read: What is the Size & Cost of Plywood? |

05. Life | |

|---|---|

| 01. It has less life span as compared to plywood. In dry environment, it generally lasts for 5 years, but if surfaces are laminated they can last even for 10 to 15 years. | 01. Plywood has a life span of 30years and can last more, if it is laminated or veneered. |

06. Cost | |

|---|---|

| 01. It is less expensive compared to plywood. | 01. It is costlier as compared to particle board. |

06. Special Comments |

|---|

| Depending upon the application area and budget, plywood and particle board should be selected. For custom made furniture which supports heavy loads and for kitchen cabinets, plywood is recommended. While for bedrooms where load is less particle board furniture may be used to lower the cost. From the above comparison of particle board vs plywood, the user needs to make a judicious and rational choice depending upon your budget. |

The popular manufacturers of particle boards and plywood in India are:

Also Read:

Advantages and Disadvantages of Plywood

Different Types of Particle Board and Their Uses

Plywood vs MDF: How to Make the Right Choice

Advantages and Disadvantages of Particle Board