Plastering work is a thin layer of mortar, applied over the masonry and it acts as a damp-proof coat over the brick masonry work. Plastering work also provides a finished surface over the masonry that is firm and smooth hence it enhances the appearance of the building. The primary objectives of plastering are to protect the surface from atmospheric influences, to cover the defective workmanship in masonry, to conceal porous materials, and to provide a suitable surface for painting.

Plastering Work

01. What are the Standard Specifications Used for the Plastering Work?

Here are the lists of plastering work specifications as per the American, British and Indian standards.

American Standards:

- ASTM C926 Standard Specification for Application of Portland Cement-Based Plaster

New Zealand Standards:

- NZS 4251-1 (2007): Solid plastering – Cement plasters for walls, ceilings and soffits [Licensed Building Practitioners Rules 2007, Building Code Compliance Documents B1 (AS1), B2 (AS1), E2 (AS1)].

European Standards:

- BS EN 998-1 Specification for mortar for masonry – Part 1: Rendering and plastering mortar.

Indian Standard (BIS codes):

- IS 383 Specification for coarse and fine aggregates for natural sources for concrete.

- IS 1542 Specifications for sand for plaster

- IS 2645 Specifications for integral cement waterproofing compound

- IS 8112 Specification for 43 grade OPC

- IS 269 Specification for 33 grade OPC

- IS 1489 Specification for Portland Pozzolana Cement

The material used for plastering work must be tested as per specification. Sand should be tested for organic impurities, silt content, the particle size of sand, and bulking of sand. Sand from the river flowing through a plane area is not suitable for construction as it shall fall within the limits of grading zone IV.

Learn more

How do I Check the Qualities of a Good Brick?

How do I Check the Quality of Sand at the Site?

How do I Check the Quality of Cement at the Site?

02. What are the Sequences of Works carried out Before Starting the Plastering Work?

Internal brick masonry must be completed before commencing the internal plastering work. In the case of external plastering work, you should have to finish the periphery brickwork of each floor first. The outside plastering work always starts from the top of the building and finished at the bottom, and ceiling plaster should be completed before commencement of wall plastering.

Learn All About Brick Masonry Construction and Its Precautions.

03. How to Manage the Materials of Plastering Work?

It is measured in area. The quantity of plastering works measured in the square meter of area. It is measured by multiplying length and height of the wall surface. The approximate materials used for 12 mm thickness in C: M 1:3 is 7.5 kg cement, and 0.015m3 sand is required per 1 m2 of plaster.The approximate materials used for 20 mm thickness in C: M 1:3 is 11.5 kg cement, and 0.024m3 sand is required per 1 m2 of plaster.

04. Which Precautions should be taken for the Scaffolding of Plastering Work?

Proper steel/wooden scaffolding must be done for the interior wall plaster to meet specific site needs. In the case of the external periphery, it should be required to make double Steel scaffolding, sufficiently strong so as to withstand all loads likely to come upon it. It should be independent of work, and have two sets of vertical supports shall be provided.

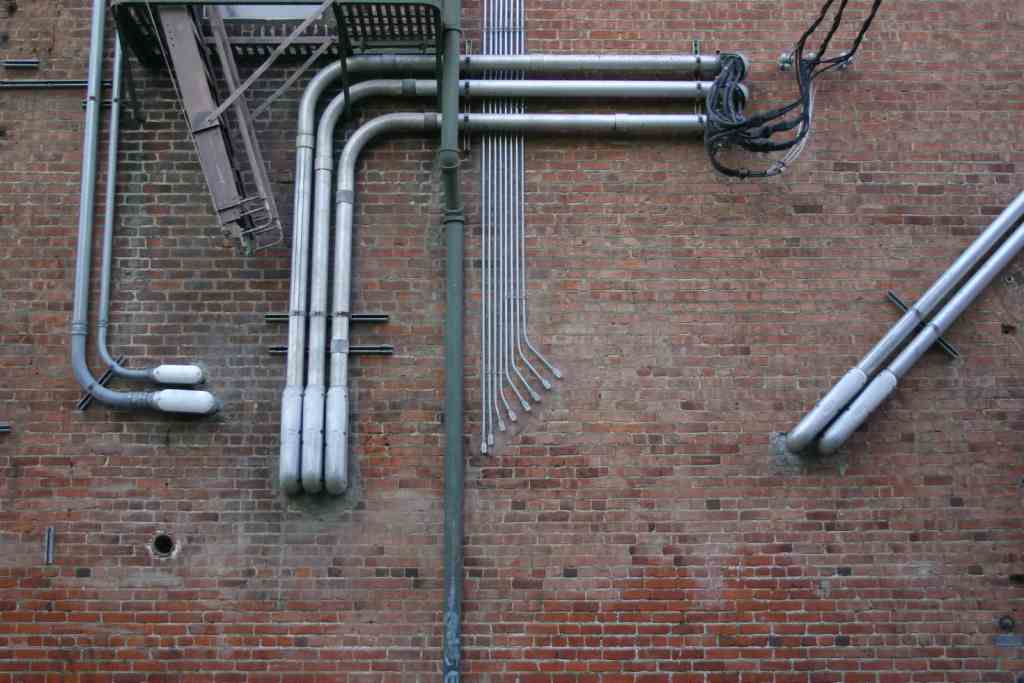

05. Which Precautions should be Taken for the Integration of Services in Plastering Work?

Integration of services like HVAC, electric conduit, and plumbing line should be installed, and proper finishing must be done. Any Grooves, and sleeves are shown in the drawing should be finished in right line, level, and position or as directed by the engineer. The sleeves of scaffolding should be finished properly and cured properly. It will help to reduce the problem of leakage in structure.

06. Which Precautions should be taken during the Workmanship of Plastering Work?

- Plastering work must be started with adequate surface preparation. The joint of the brick wall should be racked out correctly. Dust and loose mortar should be removed by brushing and scrapping. The surface should then be thoroughly washed with water, cleaned and kept wet before plastering is commenced.

- Sand should be screened through the sieve, and proportioning of cement mortar should be as per specification.

Sand Screened through the Sieve

Mortar should be used shortly after mixing, and excessive amounts of mortar should not be mixed at a time. It must be used within 30 minutes of adding water, if delayed either reject the mix or add adequate extra cement.

Learn more about readymade mortar.

- 150 mm wide chicken mesh should be provided between the junction of column/beam and wall to prevent the cracks. Nails should be used 150 mm center to center for fixing chicken mesh.

- In the case of interior cement plaster with floating coat of neat cement, the quantity of cement applied for floating coat must be 1 Kg per Sqm.

- In the case of exterior plaster of 18 mm thickness, it must be done in two coats. The first layer of 12mm thick should be left rough and furrowed 2 mm deep with scratching tool and then apply 6 mm thick second layer.

- The surface should be finished off true with a trowel and wooden float to give a smooth surface.

- It should frequently be tested as the work proceeds with a true straight edge not less than 2.5 m long and with plumb bobs. Always check line, level and plumb of the vertical or horizontal surface, edge.

07. How to Check the Plastering Work?

- Proper surface preparation must be done before commencing the plaster work.

- The materials used for plaster should be conformed to IS codes, and water cement ratio should be checked.

- Checking the level marks is necessary. The level marks should be made with fresh mortar on all four walls. So that, after plaster room size is truly square or truly rectangular. Otherwise, when you are installing tiles for the floor, you’ll face difficulties, and ultimately it will look ugly.

- It should be checked for the smooth surfaces and straight edges.

- Ensure that when we found holes in brickwork for conduit pipes, the same should be filled with cement mortar and should be adequately cured.

Filled Holes in Brickwork For Conduit Pipes

- Holes made for scaffolding should also be filled correctly and cured sufficiently because holes are the major source of leakage or dampness in the wall as curing at such location is always ignored.

08. What Care should be Taken after Completion of Plaster Work?

- Cleaning of doors or frame and floor area is necessary at the completion of work.

- Curing should be started as soon as the plaster has hardened sufficiently and must be cured for at least 7 days.

- Curing shall commence, 24 hours after the plaster is laid.

09. Which are the Safety Precautions Taken During the Plastering Work?

- Method statement for handling, placing and cleaning of materials must be prepared and must be followed.

- Personal protective equipment like safety helmet, safety belt, rubber hand gloves, goggles, facemask and rubber shoes should be ensured when handling work, and First-Aid kit is immediately available on site.

- Proper ventilation and electric lights must be provided when it is carried out in a small space and a dark place.

- The material transporting machine should be checked for calibration frequently. Any error or defect that you see on the machine should be immediately repaired. Machine operator must have recognised agency’s license.

- Cleaning of area and housekeeping of material is necessary. The wastage of materials should be removed from the site as soon as possible.

10. How to Manage or Minimise the Wastage in Plastering Work?

Wastage should be minimized by adopting proper construction methods. The waste management training program should be organised at regular interval on site. Waste materials should be stored safely and try to reuse or recycle.

11. How to Measure the Plastering Work?

As per IS 1200 – 1976 (Method of measurement of building and civil engineering work P-XII , Plastering and pointing) dimensions shall be measured to the nearest 0.01 m areas shall be worked out to the nearest 0.01 m2. The length of plaster shall be taken between the brick walls or brick partitions (the dimensions before the plaster shall be taken), and for the height of plaster shall be taken from the top of the floor or skirting to the ceiling.

For the deduction of door/window/ventilation etc. follows the provision of IS Code: 1200 – 1976.

The plasterer prepares the method statements of plastering work based on the above precautions. It will help them to manage the plastering worker. It will also assist them in timely completing of plaster work. The homeowner needs to know all the tips related to plastering work so they can deal well with the plasterer. If the homeowner knows all above given tips of plastering work, they will get the gratification of the work by achieving the good quality in plaster work.