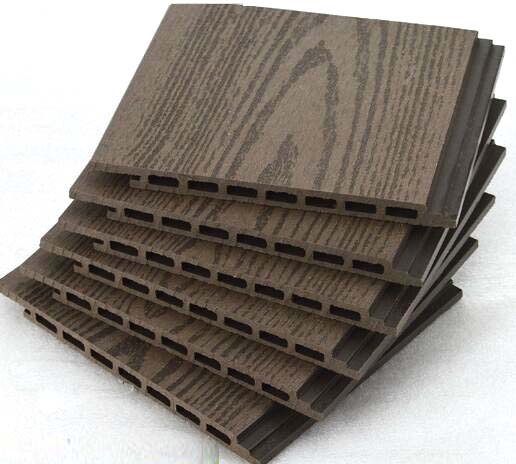

In modern era because of advancement of the technology and research every day, new materials are coming up in the construction industry which is no exception. One such material in the building construction industry is Wood Plastic Composite (WPC). It is an Eco-friendly material which is emerging as an alternative to the natural wood as well as plywood. It is a composite material which constitutes of waste Wood fibers and thermoplastics. They are mixed together to form a base material possessing thick consistency. It is then further extruded and molded to different required shapes and sizes.

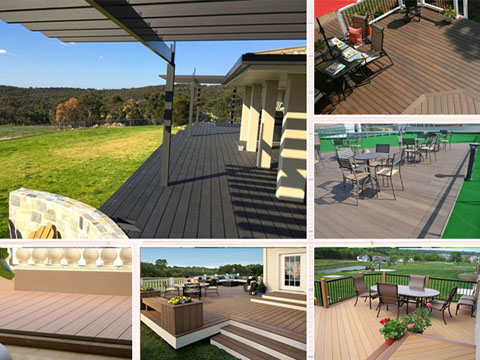

Various different colors and additives can also be added to create materials with better specifications. There is wide range of uses and applications of WPC boards in outdoor deck flooring, fences, door& window frames and outdoor landscape and so on.

In terms of percentage, it comprises of 70% of virgin polymer, 15% of wood powder(fiber) and remaining 15% of additives. It is available in size of 8 ft. X 4 ft.(2440 mm X 1220 mm) with the thickness of boards 5 mm (0.20 in.), 6 mm (0.24 in.), 7.5 mm (0.30 in.), 11 mm (0.43 in.), 12 mm (0.47 in.), 17 mm (0.67 in.) and 18 mm (0.71 in.).

Characteristics of WPC Board

There are various characteristics of WPC board which are listed below:

- The appearance and feel resembles to that of a natural wood. It requires less repair and maintenance as it does not distort/bend or chip off in small pieces like natural wood.

- It is highly resistant to moisture and hence a highly durable material.

- It also has resistance to termite and fungus.

- It does not corrode easily and does not decay or lose its constituents.

- As it is made up of recycled plastic and waste wood, hence it is sustainable and green material.

- There is a greater hold of nails, screws and fasteners when used with WPC in comparison with natural wood.

- Ten WPC Boards = Save One Tree

It is gaining popularity as it prevents the unnecessary cutting of trees and is made using waste materials in a very beneficial way to create improved building materials. One tree is saved for every ten WPC boards.

Here are various advantages and disadvantages of WPC boards:

Advantages of WPC Board

01. Quality:

- It comes with guaranteed quality which consists of modifiers, foaming agents, stabilizers and various elements that are mixed in specific and strict ratio. As there is a blend of high-quality materials, it eventually becomes a high-quality material.

02. Ease of Customization:

- As per requirements and needs, it can be moulded and shaped into different shapes and sizes. Due to this, it can be used for making of designer doors and windows which will give rich look and fine polishing. It is at present mostly used in doors, windows and home furnishings.

03. Sustainable Material:

- Paint is used or thermal transfer is done for modern and high-end surface treatment to make the WPC doors, flooring and profiles look prospering. The surface treatment provides an exclusive and attractive look to the WPC boards.

04. Substitute:

It is a promising and cost-effective substitute for the plywood due to its various characteristics listed above.

Disadvantages of WPC Board

01. Chemical Properties:

- It contains a plastic polymer and wood fibres so the shortcomings of both the materials will be present in it.

02. Resistance:

- The resistance of WPC to the extreme temperature is low as compared to wood.

03. Cost:

- The cost of WPC material is higher as compared to the other materials used for the same purpose.

04. Appearance:

- It lacks the natural wooden texture due to which the feeling of natural wood is missing when furniture or doors of this material is prepared.

Uses and Applications of WPC Board

01. Outdoor Decks:

- It is highly used in outdoor decks and patios. The manufacturers of WPC offer various decking options such as solid decking, hollow decking, mosaic decking and many more.

02. Fencing:

- As the material is secure and durable; they are widely used for the preparation of fences for gardens and other outdoor fencing purposes.

03. Paneling:

- This material is quite long lasting and as it is available in larger size, this allows the use of this material in indoor as well as outdoor panelling.

04. Interior Areas:

- WPC boards are also used in the interior areas for making of various furniture items such as wardrobes, kitchen cabinets, interior partitions, bathroom vanities and also in the ceiling of the room.

WPC board is now an emerging material which is modern and long-lasting, replacing the traditional construction materials due to its strength, modern designs and many more characteristics.

Hope this article is helpful in providing you with the basic knowledge of Wood Plastic Composite (WPC) board.

Stay tuned to our website gharpedia.com for any updates on the materials and house-related solutions in easy way and easy language.

Also Read:

Plywood Buying Guide: Choose the Good Quality Plywood

What is the Size and Cost of Plywood?

Image Courtesy: Image 1, Image 2, Image 3, Image 4, Image 5, Image 6