The myriad of seasons which Mother nature presents has inspired the greatest poets of all times. However, it comes with its own troubles especially for the construction business. Each season has its own levels of humidity, temperature and day hours. Therefore, if you are in the construction business, you need to know what stays and what doesn’t in this line.

In this article, we will be discussing the features, do’s and don’ts of cold weather concreting. The knowledge about cold weather concreting is essential in countries like America, Russia, Canada, et where the inhabitants experience near zero and sub-zero temperatures and when it comes to India – the Himalayan regions and when compared with the warmer climate, the concreting procedure in cold weather is different and difficult.

Concreting refers to the procedure of concrete batching, mixing, transporting, placing, compacting and finishing etc. which is the most essential procedure for each construction project. Some of the specific concreting procedures such as batching of concrete, mixing of concrete, transportation of concrete and placing of concrete, etc. have been described in our previous articles.

What Temperature is too Cold for Concreting?

According to The American Concrete Institute under ACI 306R- 16, the conditions of cold weather concreting exist when the air temperature has fallen to, or is expected to fall below, 40°F (4°C) during the protection period. The protection period can be defined as the amount of time recommended to prevent concrete from being adversely affected by the exposure to cold weather during construction.

Cold Weather Concreting

How the Low Temperature Can Affect the Concrete?

It is known that concrete gets transformed from semi-liquid to solid or plastic state and further into hardened state due to a chemical reaction known as hydration. The rate of hydration depends on the temperature i.e. the rate of hydration increases or decreases according to the rise and fall in temperature. If hydration is low than the process of transforming from semi-liquid to a solid is delayed and this in turn affects the quality of concrete as well as the economy of construction. Thus, it is essential to ensure that the temperature is maintained during the placing of concrete and it should be above 4°C or 40°F. Cold weather can have a detrimental effect on concrete for various reasons which are as follows.

Effects of Cold Weather on Concrete

(a) Delay in Setting and Hardening of Concrete

The setting of concrete is a stage in which concrete gets stiff to acquire the shape and hardening of concrete is a stage of where its strength is developed so that the concrete can carry the intended load. Both depend on the rate of hydration and rate of hydration depends upon the temperature. If the temperature is low, concrete takes longer time to set as well as to harden. The delay in setting time makes concrete vulnerable to frost attack and other disruptions. This delay can also prevent the removal of formwork in a short time period due to which the rate of work progress slows down and affects the economy of the construction in general.

(b) Freezing of Concrete at an Early Age

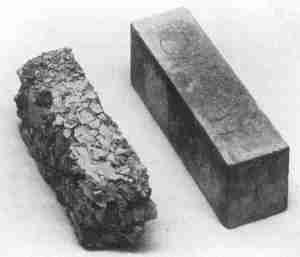

Freezing of concrete is the development of solid water i.e. ice within the paste that disrupts the hardening process and causes frost lenses to develop in the paste. Wondering how it happens? Read on to know the process.

In the fresh concrete, pores are filled with water. When the temperature goes below the freezing point, the free water contained in the plastic concrete freezes. When water freezes into ice, it occupies almost 9% more volume than the water. Freezing of water also prevents the hydration of cement and makes the concrete expand. This expansion accelerates the deterioration of concrete.

(c) Repeated Freezing and Thawing of Concrete

Climatic condition varies in the cold weather regions due to which fresh concrete or hardened concrete gets exposed to freezing and thawing cycles and will continue throughout successive winter seasons resulting in repeated loss of concrete surface and its qualities such as durability of concrete. Freezing and thawing may also exert fatigue in the concrete.

Freezing and Thawing Effect

(d) Stresses Due to Temperature Differentials

In the cold weather, large temperature differentials are likely to occur at the time of removal of form insulations. Such temperature differentials within the concrete member may promote cracking which can harmfully affect the durability.

Points to be Remembered during Cold Weather Concreting

General precautions and recommendations are given below which may help you in the cold weather concreting:

01. Pre-Preparation of Cold Weather Concreting

- Prior preparation of the concreting and as precautions for cold weather concreting work strategies should be taken. Such as erecting windbreakers to protect the mixing and batching plant, materials, forms, plastic sheets and other covering and insulating materials are available at the site.

- Well-defined temperature record chart including concrete temperature and exterior temperature should be kept on site.

- Before placing of concrete, all frozen materials like ice, snow and frost should be cleaned from the ground and never place concrete over frozen subgrade or on something that contains frozen materials.

- Freshly excavated earth should be covered with insulated blankets to preserve the natural warmth of the subsoil and keep the concrete blankets on till you begin pouring the concrete.

02. Ingredients Used for Cold Weather Concrete

- It is recommended to have a low slump and nominal water-cement ratio in cold weather concrete to reduce the bleeding and decreasing setting time. Don’t seal freshly placed concrete until it has bled and the setting process has begun.

- Air entraining admixtures can also be used in cold weather concrete and it should have the correct amount of air entrained voids that will resist freezing and thawing

- Concrete accelerator may also help to reduce the effect of freezing and thawing.

- High-early-strength cement can also be used.

- When there is no other option, adding cement to the mix will help to a certain extent for maintaining the concrete temperature.

Also Read:

Importance of Concrete Admixtures & their Types

Superplasticizers (High Range Water Reducer): For High-Performance Concrete

03. Concrete Covering Material

- During the cold weather, surface of the concrete should be covered to preserve the heat and help in the prevention of freezing. You can use concrete covering material such as expanded polystyrene, plastic sheets and waterproof paper etc.

- Heated enclosures or insulation blankets are commonly used for protecting concrete when air temperatures are near or below freezing point. Ensure that enclosures or insulation blankets all windproof and weatherproof.

- Enclosures may be heated by steam, steam pipes and other types of heaters. It can also be made of wood, canvas, fibre insulation board, plywood etc.

04. Formwork

- Insulating material should be placed against any formwork before concreting and the same can be used as protection after the formwork has been stripped.

- Forms should not be released until the concrete has achieved the strength of at least twice the stress to which the concrete may be subjected at the time of removal of formwork.

05. Cold Weather Concrete Curing

- In cold weather concrete curing, water curing is not necessary because of the loss of moisture from the concrete through evaporation is greatly reduced in cold air conditions.

- One can use the concrete curing blankets in cold weather concrete curing to prevent freezing and keep the concrete at an optimum curing temperature.

Curing Blanket

06. Inspection During Cold Weather Concreting

- When pouring concrete in cold weather, keep some personal inspection data such as a record of the date, time, external air temperature, temperature of concrete at the time of placing and general weather (calm, windy, clear, cloudy, etc.)

This knowledge is helpful and essential to homeowners and businesses who hire concrete contractors and deal with such kind of weather condition as in the cold weather concreting, concrete will develop sufficient strength and durability to satisfy the proposed service recommendations only when it is properly proportioned, produced, placed, and protected. Thus, it’s essential to increase the degree of protection as the ambient temperature decreases.

We hope this article will help you to clear your doubts regarding the cold weather concreting. stay tuned to know more facts about houses and construction.

Also Read:

Sealing and Coating of Concrete

5 Right Steps for Repairing of Concrete

Image Courtesy: Image 1 – giatecscientific, Image2, Image 3 – forconstructionpros