The construction industry has gained momentum in the recent years and is giving tough competition to other businesses all over the world. This is due to the fast-growing advancement in both construction materials and technology that has contributed in its pace and progress. Materials likes concrete plays a vital role in construction. Concrete’s versatility, sustainability, durability and economy are the properties which have made it the world’s most used material in the construction. There are so many different types of concrete in construction and ferrocement is one of them. In the article below we shall see detail information regarding ferrocement, its construction method, application, advantages, disadvantages etc.

History of Ferrocement

Ferrocement was developed by P.L. Nervi, an Italian architect and engineer in 1940. Ferrocement is the first invention of reinforced concrete. The first structure that was developed out of ferrocement was the boat.

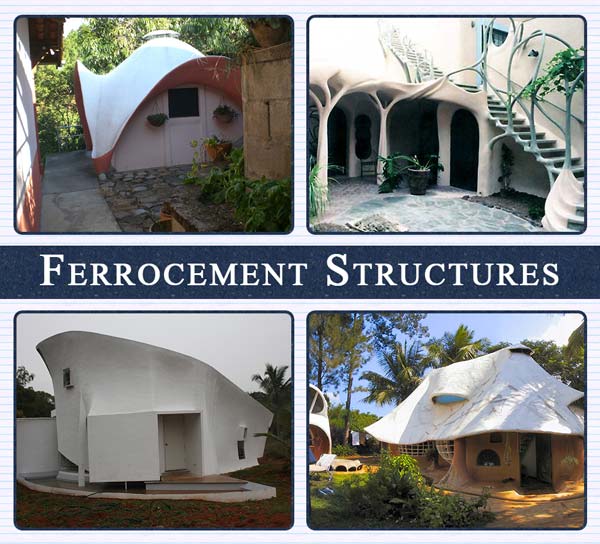

What is Ferrocement?

- Ferrocement is relatively a new material which consist of cement mortar and wire meshes. Ferrocement is also known as ‘ferrocrete’.

- As the name suggests, ferrocement is the composition of two materials i.e. Ferro (Iron) and cement (cement mortar). Ferrocement is a building technique that allows a very flexible form of member or structure to be made with concrete.

- Ferrocement is a composite material composed of mortar reinforced with light steel fabric/mesh, used to form thin members. The construction method consists of forming the shape of the required structure with a mesh of fine reinforcement, such as chicken mesh or expanded metal. Multiple layers can be used to achieve the required density of steel and the whole can be stiffened with a few standard reinforcing bars. A stiff mortar is then applied to both sides of the layer of reinforcement known as the ‘armature’) and finished to the required thickness.

- It is a composite, formed with closely knit wire mesh; tightly wound round skeletal steel and impregnated with rich hydraulic cement mortar. The wire mesh can be made of metallic or any other suitable materials.

- The wire mesh is normally of 0.5 to 1.0 mm dia. wire at 5 mm to 10 mm spacing and cement mortar have cement sand ratio of 1:2 or 1:3 with water/cement ratio of 0.4 to 0.45.

- According to ‘M. S. Shetty’ (Author of Concrete Technology), the ferrocement elements are generally of 2 to 3 cm. in thickness with 2 to 3 mm external cover to the reinforcement. The steel content in ferrocement varies between 300 kg to 500 kg per cubic meter of mortar.

- Mortar provides the mass and wire mesh provides tensile strength and ductility.

- While building ferrocement structures, the sand/cement mortar is applied to the reinforcing wire with a trowel. Do not pour sand/cement mortar which we usually do while in general concrete work.

- Unlike conventional concrete, ferrocement reinforcement (wire mesh) can be assembled into its final desired shape and the mortar mix can be plastered directly in the desired place without the using a form. But, in case we want to have any specific or special desired shape, form must be used.

- Ferrocement components have high strength as the cement content is very high. Since the steel is spread over the area, the ferrocement components are usually homogeneous in composition.

- Ferrocement is a super reinforced concrete. It differs from conventional concrete as it contains higher ratio of steel as compared to cement mortar.

- In order to make ferrocement structure, we alter the ratio of cement/steel in a required proportion that actually produces a material which exhibits properties superior either to cement or steel or both

- Ferrocement though holds quite a number of properties of steel, yet the best part is, it does not rust. It appears like concrete. It can flex/bend without cracking.

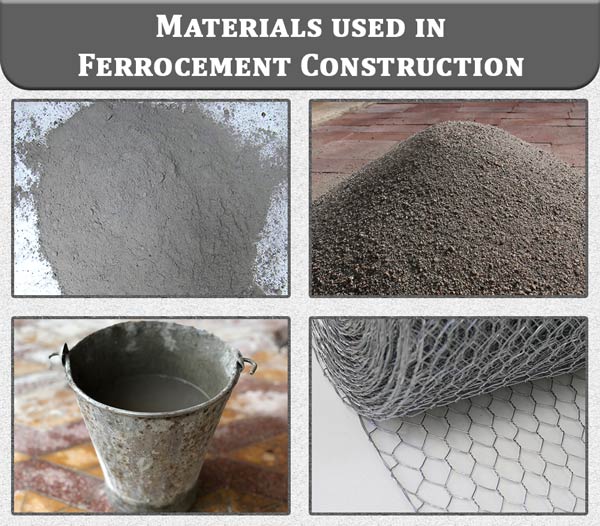

Materials Used in Ferrocement

- Cement

- Fine Aggregates

- Admixtures

- Steel Wire Meshes

- Skeleton Steel

- Water

Casting Techniques of Ferrocement

There are four methods of casting:

(a) Hand plastering

(b) Semi-mechanized process (using hand plastering)

(c) Centrifuging

(d) Guniting

Methodology of Forming Ferrocement Members

A ferrocement structure is formed by fabricating the mesh reinforcement to the shape and size of the structure initially and then mortared and cured. Method of constructing a ferrocement element is as follows:

01. Welding Skeletal Steel Framework:

A skeleton of steel bars is welded to the exact geometrical shape and size of the structure. This provides a rigid framework of the appropriate shape and size with the correct line and level.

02. Tying Mesh Reinforcement Tightly Over it to Form the Cage:

In this method, Weld mesh and fine wire chicken mesh are tied over this welded skeleton by stretching and tying technique. ‘Tightly tying meshes’ is the key point in ferrocement construction.

03. Impregnating the Mesh Cage with Rich Cement Mortar, Finishing and Curing:

The stiff cement mortar is filled in the mesh layers by press fill method. In press fill method, the mortar is to be pressed inside the wire meshes from both the sides.

Essentially, all these steps in construction are to be followed in the above-mentioned sequence. For a large size ferrocement constructions, one can work simultaneously on all the three operations.

Properties of Ferrocement

- Ferrocement members are durable and versatile material

- Ferrocement has low w/c ratio and produces impermeable structures

- It has less shrinkage and weight

- Ferrocement structures have high tensile strength, stiffness and rigidity

- They have a better impact and punching shear resistance. Ferrocement members undergo large deformation before cracking

Advantages of Ferrocement

- It has got a higher ratio of tensile strength to weight and superior cracking behaviour compared to R.C.C. They comprise of thin elements and light structures hence, they are lighter in weight.

- can be casted in any desired shape and size for wide ranges of uses.

- It provides better resistance to fire, earthquake, and corrosion than traditional materials, such as wood, adobe and stone masonry in residential construction.

- The materials are relatively inexpensive, and can usually be obtained locally.

- Only a few simple hand tools are needed to build uncomplicated structures.

- Repairs in ferrocement structure are usually easy and inexpensive which means it has low maintenance cost.

- It is easy to handle.

- Ferrocement saves 20% cost and materials.

- There’s reduction in cost economy and speed, both can be achieved.

- It has less thermal conductivity as compared to RCC.

Disadvantages of Ferrocement

01. Excessive shrinkage occurs due to higher cement content. Thus, it requires constant curing for a period of 7 days to avoid any such shrinkage cracks.

02. It is prone to corrosion of wire mesh due to incomplete coverage of steel by mortar.

03. Ferrocement is labour intensive and hence not a good choice where the labour costs are high.

04. As ferrocement construction are usually thin structures, buckling is another factor that needs to be taken into consideration.

05. Being thin ferrocement members, they have poor impact resistance.

06. Structures made of by ferrocement can be punctured by forceful collision with pointed objects.

07. They have low shear strength and low ductility.

08. Ferrocement are susceptible to stress rupture failure.

09. It is hard to do welding, drilling, nailing, screwing etc. properly in ferrocement construction.

10. According to ‘A. M. Neville’ (Author of Concrete Technology), the manufacturing process is labour intensive and therefore, ferrocement is rather expensive to produce.

Application/Uses of Ferrocement

- Ferrocement has been used for casting domestic over-head tanks. The tank being light and flexible, can be transported and hoisted without much difficulty. The ferrocement tank will be cheaper than any other competitive materials.

- Similar tanks or slightly modified tanks can be used as grain silos in villages. The ferrocement tank will help in preserving the grain unaffected by moisture and rodents.

- Similar ferrocement container can be used as a gas holder unit in Gobbar gas plants with a few modifications. Ferrocement tanks can also be used as septic tank units.

- The properties of ferrocement makes it an ideal material for boat building. It is also used in marine applications i.e. fishing vessels, barges, cargo tugs, flotation buoys. Many countries notably China are manufacturing ferrocement boats and fishing trawlers on large scale.

- Manhole cover of ferrocement is becoming very popular. They are replacing cast iron manhole cover over sewers around the domestic buildings where they are not subjected to heavy vehicular traffic. It is also used in sedimentation tanks, swimming pool linings, well casings, septic tanks etc.

- Ferrocement is becoming a popular material for prefabricated roof It is also used in residential building application such as community centers, precast housing elements, corrugated roofing sheets, wall panels etc.

- Ferrocement is a suitable material for pressure pipes. It is much lighter compared to normal reinforced concrete pipes.

- Ferrocement is found to be a suitable material for casting curved benches for parks, garden and open-air cinema theatre.

- It is also an ideal material for making tree guards which can be cast in two parts to facilitate its removal at a later date.

- Ferrocement is widely used to create a sculpture of various shape.

- Ferrocement has also been used in agricultural application i.e. canal linings, shells for fish and poultry farms.

To sum up, ferrocement techniques though of recent origin, have been extensively used in many countries, notably in the U.K., New Zealand and China. There is a growing awareness about advantages of this technique of construction all over the world. It is well known that conventional reinforced concrete members are too heavy, brittle and, because they develop cracks, they cannot be satisfactorily repaired if damaged. The above disadvantages of normal concrete make it inefficient for certain types of work. And then, ferrocement is a better replacement at such places. Hope, the article serves the best of its purpose by giving you an idea as to how ferrocement differs from the conventional concrete.

Must Read:

Basics of Fibre Reinforced Concrete

11 Factors that can Affect the Strength of Concrete

Fire Resistance of Concrete | Fire Resistive Construction

Image Courtesy: Image 1(a), Image 1(b), Image 1(c), Image 3(a), Image 3(b), Image 4, Image 5, Image 7