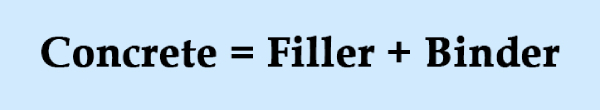

Concrete is a mixture of water, sand, aggregate and cement which forms a stone-like mass on setting. The word Concrete is derived from the Latin word “concretus”, meaning “to grow together”. Concrete is a composition of coarse granular material (the aggregate or filler) embedded in a hard matrix of material (the cement or binder) that fills the space between the aggregate particles and glues them together.

According to ‘Zongjin Li’ (Author of Advanced Concrete Technology), in simple words, Concrete can be defined as a combination of filler and binder.

Definition of Concrete

Depending on the type of filler and binder used, concrete is named accordingly like Plum concrete, Rice hull concrete, fly ash concrete etc. In this article, let us discuss what a plum concrete is and how Plum is used as a filler material in plum concrete.

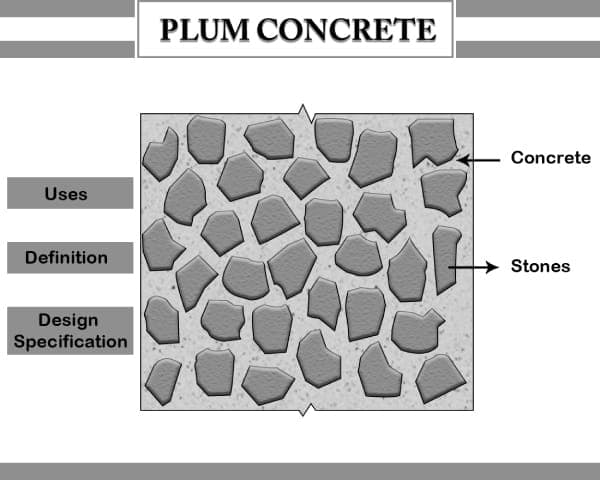

What is Plum Concrete?

According to ‘Er. M. K. Gupta’ (Author of Nabhi’s Practical Handbook on Building Construction), the term Plum refers to the hard, clean natural stones used in mass concrete of foundations, gravity dams, embankments and other mass concrete works.

Plum concrete is formed by the inclusion of medium to large stones of size up to 300mm or even larger as filler. It is used to increase the apparent yield of concrete for a given amount of cement i.e. to avoid using excess amount of cement without compromising on the strength.

The large stones used are known as plums. These plums are used in the making of mass concrete. However, the volume of plums should not exceed 30% – 40% of the total volume of the finished concrete. Plum concrete is also referred to as Rubble concrete or Cyclopean Concrete. The Plum should not be larger than one-third or the cross-section of the concrete mixer.

According to the Technical Specifications of United States of America, “Cyclopean concrete shall be constructed with a mixture of 60% plain concrete and 40% large stones. The plain concrete used in this job shall have a minimum resistance of 180 kg/cm2 on the 28th day, and the materials should be saturated before creating the mixture. Stone material should comply with the ASTM standard and specification will be according to the concrete design.”

How is Plum Concrete Different from Plain Cement Concrete (PCC)

Plain cement concrete is the simplest form of concrete. It is manufactured by mixing essential ingredients such as cement, fine aggregates and coarse aggregates. While plum concrete is the type of concrete in which medium to large stones are used as filler material in place of aggregates.

Hence the only difference between plain cement concrete and plum concrete is the addition of the large boulders in the concrete mix. It acts as a filler material reducing the quantity of small size aggregates which are generally expensive. Thus, it helps in cutting down the cost of concrete.

Also Read: What is Plain Cement Concrete (PCC) in Construction of Foundation?

Manufacturing Process of Plum Concrete

Plum concrete also called Rubble concrete or Cyclopean Concrete can be manufactured in two simple ways. It can either be manufactured by adding the plum to the concrete mix during the mixing of concrete or by spreading the plums over the layer of normal concrete and then spreading another layer of concrete. Special attention must be given while placing the plums in the concrete to prevent air traps. The general manufacturing process is as follows:

01. Quality of Plum Material

- The stones used as plum material must be strong, durable and preferably should be of the same rock from which aggregates are manufactured.

- It should not be flaky and should contain any dirt or clay.

- If any dust is found on the surface of the plum material, it must be cleaned before use.

02. Batching of Plum Material

- First, the stones required for the manufacturing process of plum concrete are carefully hand-picked. Thus, the batching of the plum material is done. The size of the plum material should be up to approximately 300mm.

- The size of the plum material should be limited to around 1/3rd of the total volume of concrete. The plum material can either be hand-picked or just randomly picked by the workers and brought to the site.

03. Placing of Plum Concrete

- The plum material is spread over the surface with a spacing specified as per NHA (National Highway Authority – Pakistan) General Specifications. If the plum material is placed close to each other, then the concrete required will decrease up to 50%, and the quantity of plum will increase up to 50% of the total volume of plum concrete.

- Once the plum material is spread, a layer of concrete is poured over it. After the concrete slowly fills around the gaps between the plum materials, another layer of plum material is spread over the concrete. This process is repeated until the desired level is reached. While placing of plum concrete, special attention must be given to avoid air traps as it may decrease the strength of the plum concrete. Also, one has to ensure that they are placed randomly.

04. Finishing and Curing

- Once all the layers of plum concrete are carefully placed, it is given a neat finishing and left for curing up to minimum 14 days. Curing can be done in various ways. Either water can be sprayed at regular intervals of time or the plum concrete can be covered with wet jute bags.

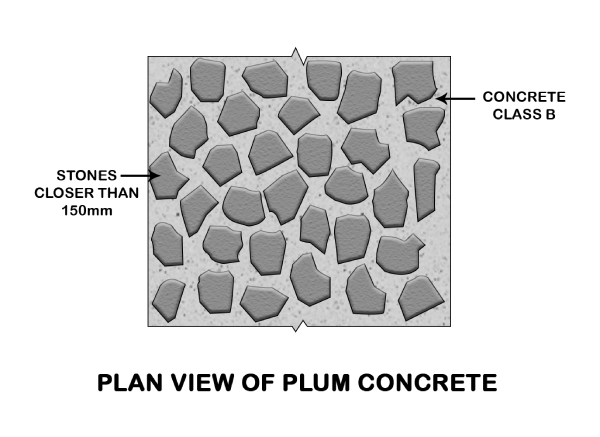

Design Specifications of Plum Concrete

The design specifications for plum concrete as per National Highway Authority General Specifications – Pakistan (40 1.3.6.f) are as follows:

- The plum concrete must belong to the Class B concrete which consists of large boulders embedded in it.

- The total volume of the plums shall not be greater than one third of the total volume of the portion of the work in which it is placed. (i.e. 33%)

- The grade used for the manufacturing of plum concrete shall depend upon its ultimate use and its strength requirements accordingly. But minimum recommended is M20.

- The least dimension of stone/plum is 150mm in certain conditions, whereas the maximum size depends on size of structure.

- Each stone shall be surrounded by at least 150mm of concrete.

- The formwork provided for placing the plum concrete should be of either steel plates or plywood formwork.

- The time for curing should be at least 7-14 days.

Uses of Plum Concrete

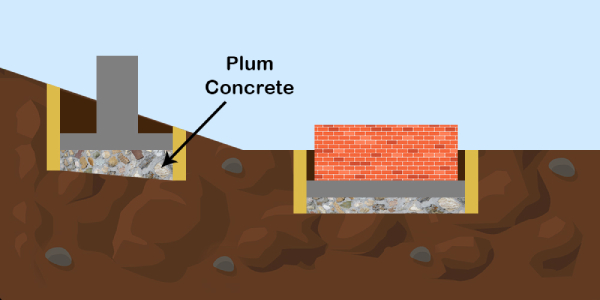

01. Sloping or uneven Surface

- This type of concrete is mainly used to level the ground below the foundation, where the surface is uneven. Additionally, it is also used to level the surfaces in the places of sloping ground.

- The use of plum concrete in the foundation enables minimization of the cost. In the case of sloping ground, the plum concrete provides additional stability to the structure.

- It is also used for machine foundation where mass concreting is needed only to increase the mass of foundation.

Plum Concrete for Sloping or Uneven Surface

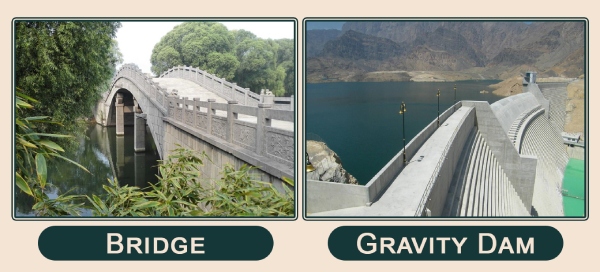

02. Gravity Dams and Bridges

- Plum concrete finds a higher requirement in the construction of massive structures such as gravity dams and bridges. But the permissible size of the plum material used for the construction of bridges and dams is restricted to 150mm.

Use of Plum Concrete for Bridge & Gravity Dam

03. Water Channels

- Plum concrete is used to level the bed surfaces of the water channels. Since the water channels are usually placed underground, it requires more strength and durability. Hence, plum concrete is the best choice for such structures.

04. Road Embankment

- One of the most common uses of plum concrete is in the construction of road embankments. It is used in making side slopes for an embankment to provide a protective layer to an earthen foundation.

05. Machine Foundation

- It is frequently used in machine foundation, where large mass is needed for safety of foundation and machine. It provides an economical choice there.

Conclusion

Concrete is one of the most versatile and widely produced construction material in the world. Due to the unique advantage of concrete, it will continue to be the most popular and widely used. The ever-increasing population, living standard and economic development lead to increasing demand for infrastructure development and hence volume of concrete required for mass concreting is also increasing day by day.

As discussed, concrete is composed of different graded aggregates or fillers embedded in a hardened matrix of cementitious materials, admixtures and water. Plum concrete is a type of concrete in which medium to large sized stones are used as a filler material. By using large sized filler stones, the cost of concrete is reduced without affecting strength or performance of the structure.

Plum Concrete is used when large quantity of concrete is needed below the foundation or footing of a structure to achieve a level surface for equal distribution of load. For large volume construction where mass concreting is needed, plum concrete (also called as rubble concrete, or cyclopean concrete) is proved to be an economical choice.

Must Read:

What is Concrete Mix Design (CMD)?

Why Water Requirement is Higher for Curing rather than Making Concrete?

Methods for Mixing of Concrete Their Procedure & Precautions

Image Courtesy: Image 2

Author Bio

Arfa Falak – My name is Arfa Falak and I have my graduation in BE (civil). I live in Bangalore. I am an aspiring design Engineer.