The occurrence of various crack patterns in the building mostly takes place during construction and/or after completion. A building component develops cracks whenever the stress in the components exceeds its strength. Stress in the building component is caused by externally applied forces/loads.

Almost all the types of cracks in Reinforced Concrete Beams are fundamentally defined by the principle cause or mechanism associated with the function of cracks.

Types of Cracks Occurred in RCC Beams

Here we have tried to provide you with an overview of almost all the types of cracks occurred in RCC beams.

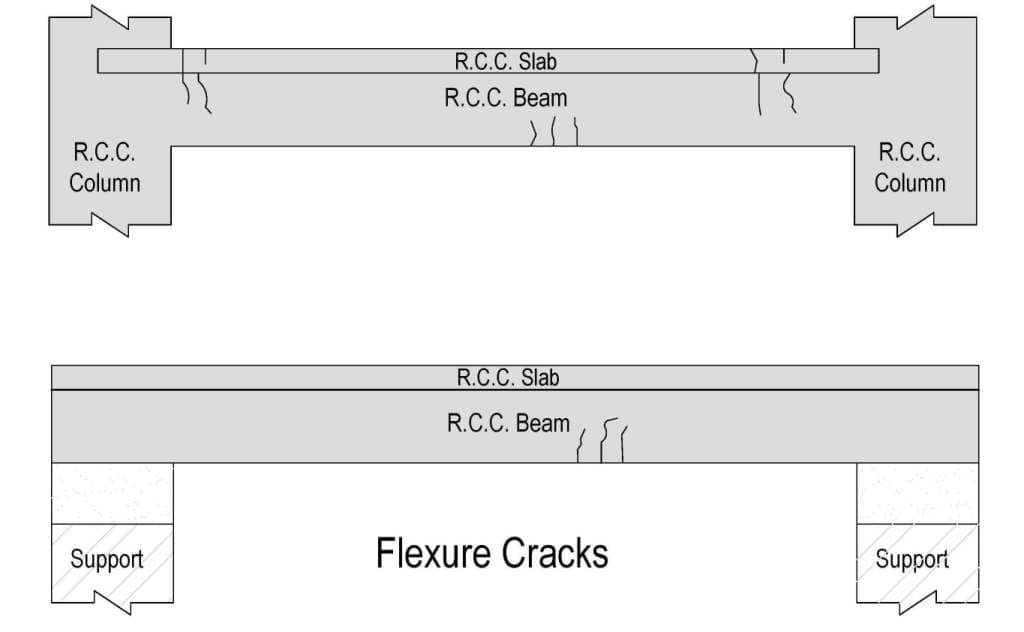

01. Flexure Cracks in Reinforced Concrete Beams

Flexure word also means “Bending”. Cracking in reinforced concrete beams subjected to bending usually starts in the tensile zone i.e. soffit of the beam. The width of flexural cracks in reinforced concrete beams for short-term may stay narrow from the surface to the steel. However, in long-term under continuous loading, the width of crack may get increased and become more uniform across the member.

Flexure Cracks in Reinforced Concrete Beams

Member

- R C Beam

Important Characteristics

- Originates in maximum moment region (in above image this region is in centre of the beam, it varies as per support Conditions of beam)

- May be single or in groups

- Maximum width at bottom/top of beam

Possible Reasons

- Flexural capacity of the beam is inadequate.

- When Cross section of the beam or main reinforcement in beam is insufficient.

- i.e. it is loaded more than defined loads.

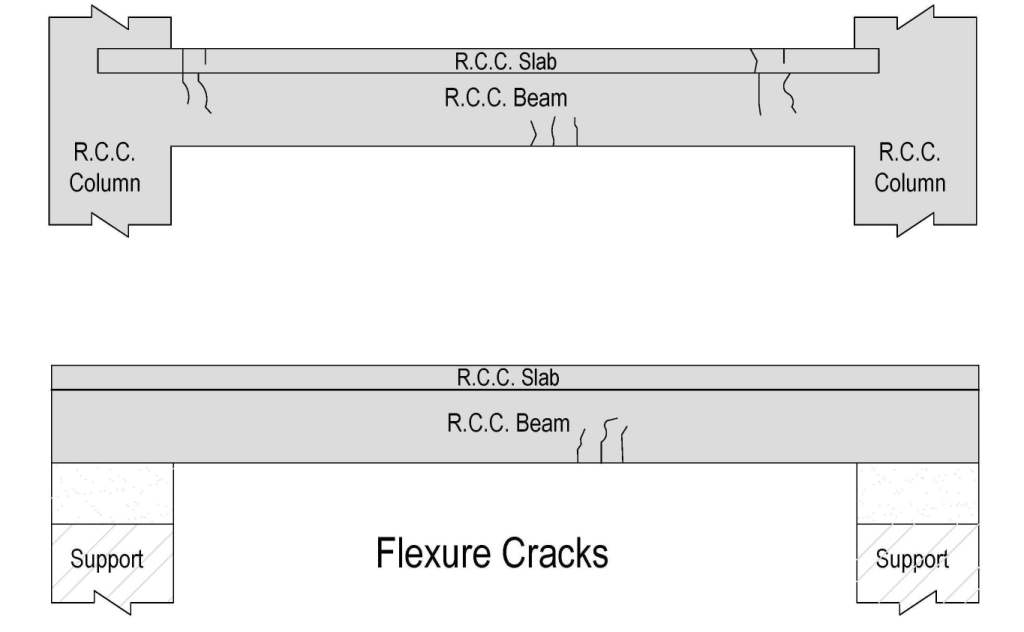

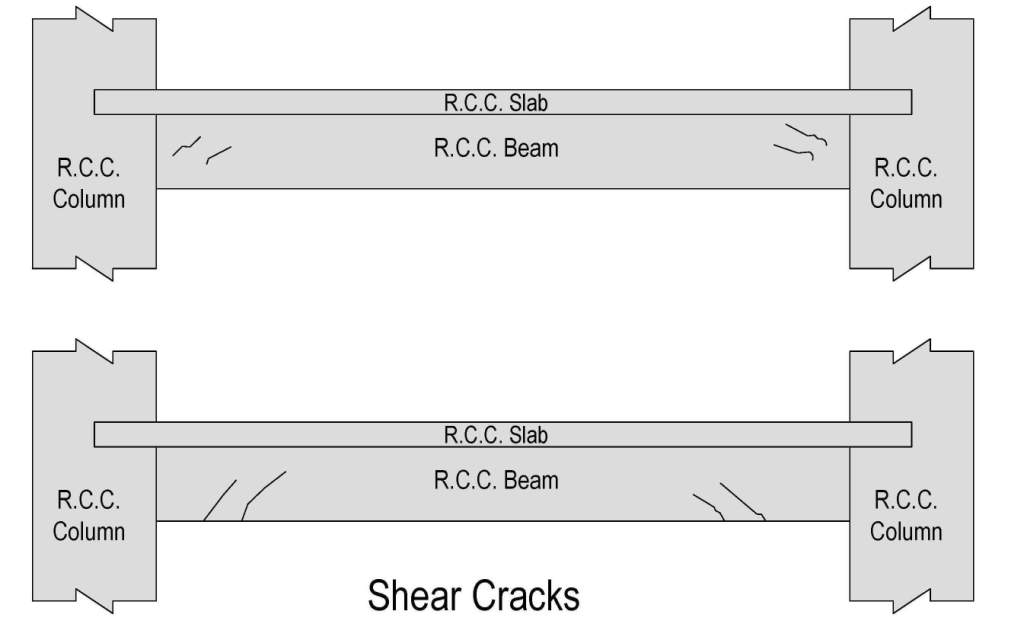

02. Shear Cracks in Reinforced Concrete Beams

Shear cracks in reinforced concrete beams occur in hardened stage and it is usually caused by structural (self-weight) loading or movement. These types of cracks are better illustrates as diagonal tension cracks due to combined effects of flexural (bending) & shearing action.

Shear Cracks In Reinforced Concrete Beams

Member

- R C Beam

Important Characteristics

- Originates nearer to supports.

- Maybe single or in groups.

- Maximum width at neutral axis region or at bottom of beam.

Possible Reasons

- Shear Capacity of the beam is inadequate.

- Cross section or torsional reinforcement insufficient.

- Both here happen due to loading more than designed load.

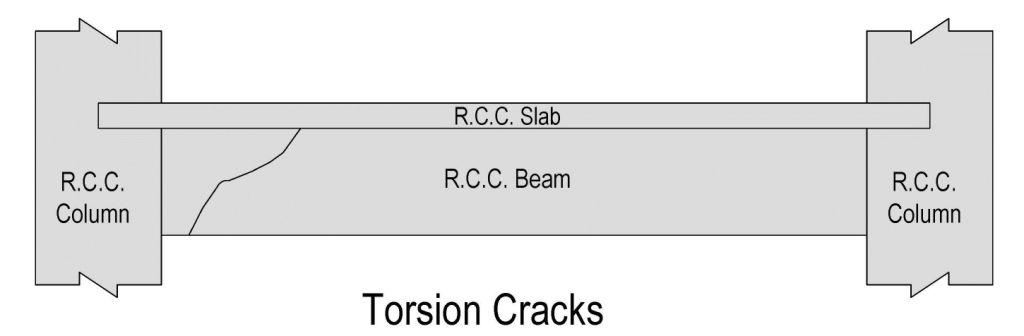

03. Torsional Cracks in Reinforced Concrete Beams

Usually beams are subjected to torsion along with bending moment and shear force. Bending moment & shear force occurs as loads acts normal to the plane of bending. However, loads away from the bending plane will causes torsional movement.

Torsional Cracks in Reinforced Concrete Beams

Member

- R C Beam

Important Characteristics

- Originates nearer to maximum torsion region.

- Single generally uniform width. Appears over the whole periphery in helical form

Possible Reasons

- Torsional strength of the beam is inadequate.

- Cross-section or torsional reinforcement insufficient.

04. Corrosion Cracks in Reinforced Concrete Beams

Corrosion cracks in reinforced concrete beams runs along the line of reinforcement. It usually separates the concrete from reinforcing bars. It is mostly manifested by discolouration of paint or stains of rust.

Corrosion Cracks in Reinforced Concrete Beams

Member

- R C Beam

Important Characteristics

- Runs along the line of reinforcement.

- Uniform width in general

Possible Reasons

- Bond between reinforcing bars and concrete not satisfactory.

- May be due to corrosion of bars/fire damage.

Also Read: Identify Risk of Steel Corrosion in Concrete Structure

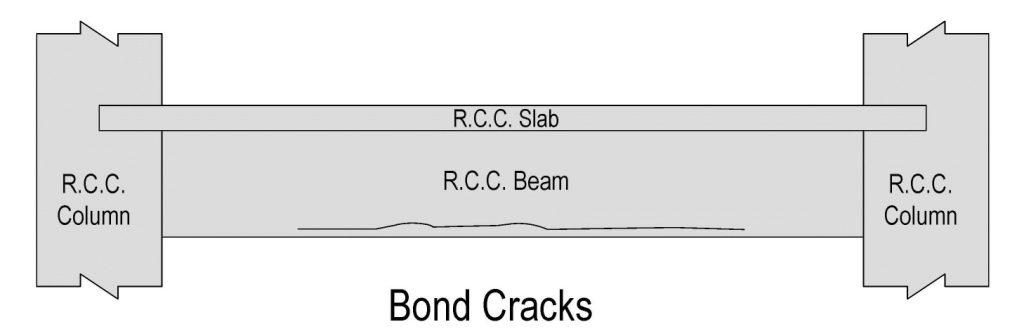

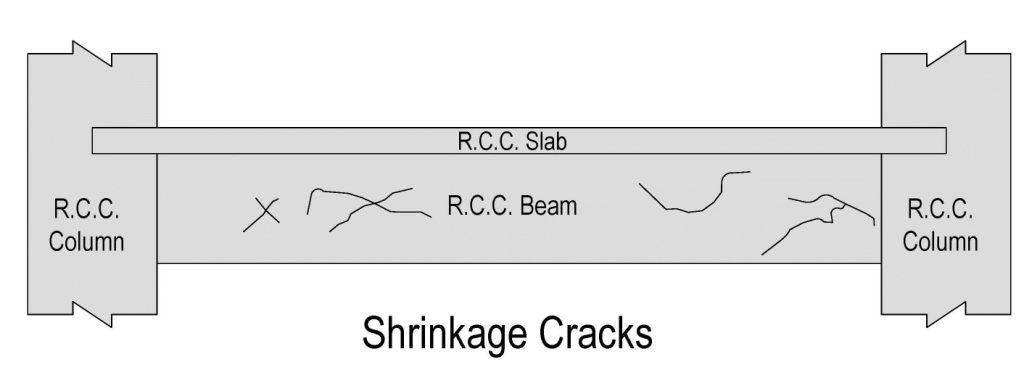

05. Shrinkage Cracks in Reinforced Concrete Beams

Shrinkage cracks in reinforced concrete beams occur during two stages, which are pre-hardening stage and hardened stage. In pre-hardening stage these types of cracks are called as plastic shrinkage cracks & in hardened stage they are known as drying shrinkage cracks. Shrinkage cracks occur when fresh concrete is subjected to a very rapid loss of moisture.

Shrinkage Cracks in Reinforced Concrete Beams

Member

- R C Beam

Important Characteristics

- No regular pattern or thickness and in general superficial.

Possible Reasons

- Curing is inadequate or no control over water-cement ratio.

- Usage of an excessively rich mix.

- Shrinkage reinforcement, if any, insufficient.

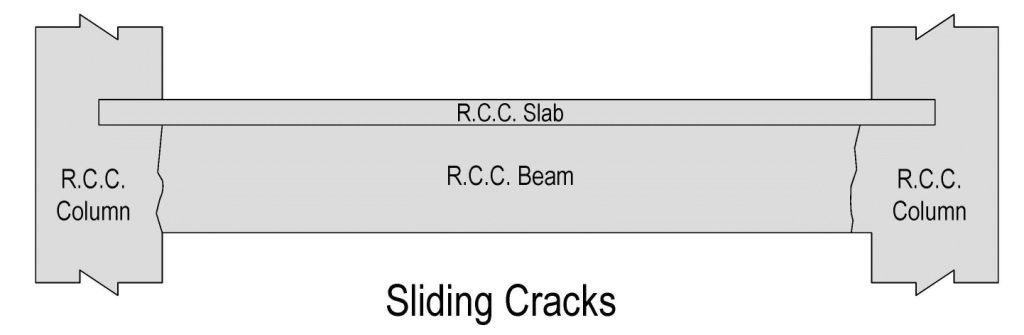

06. Sliding Cracks in Reinforced Concrete Beams

The diagonal mode of failure by sliding along the critical cracks is known as failure by sliding and usually appears at the edge of the supports of beam. These types of concrete cracks appear if concrete gets disturbed in fresh state.

Sliding Cracks in Reinforced Concrete Beams

Member

- R C Beam

Important Characteristics

- Runs vertically at the edge of supports.

- Maximum width at bottom of the beam.

Possible Reasons

- Concrete in a beam is disturbed at an early age when adequate strength not realised.

- Maybe due to disturbance of formwork at green stage or early deshuttering.

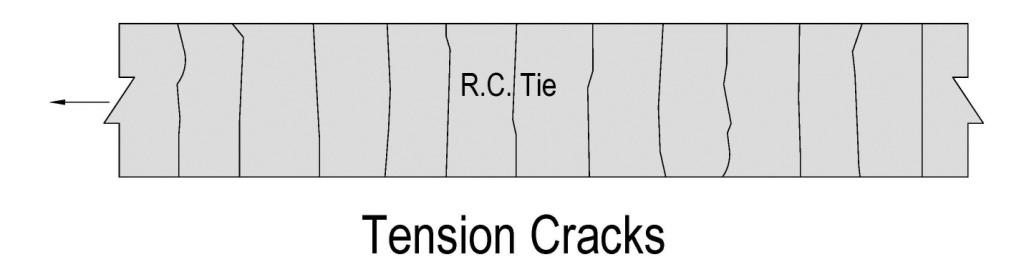

07. Tension Cracks in Reinforced Concrete Beams

Tension cracks in reinforced concrete beams occur usually due to shrinkage or temperature variations. Tension cracks usually appear in those members where restraint is provided in the longitudinal movements. Usually tension cracks tend to propagate over the full depth of the cross-section of beam.

Tension Cracks in Reinforced Concrete Beams

Member

- Reinforced Concrete Tie

Important Characteristics

- Appear over whole periphery. Generally over the whole length of the member.

- Parallel to each other.

- Uniformly observed

Possible Reasons

- Capacity of the member in tension is inadequate.

- Tensile reinforcement is insufficient.

Cracks endeavour safety of home and ultimately may put you in stress in long term.

Must Read: