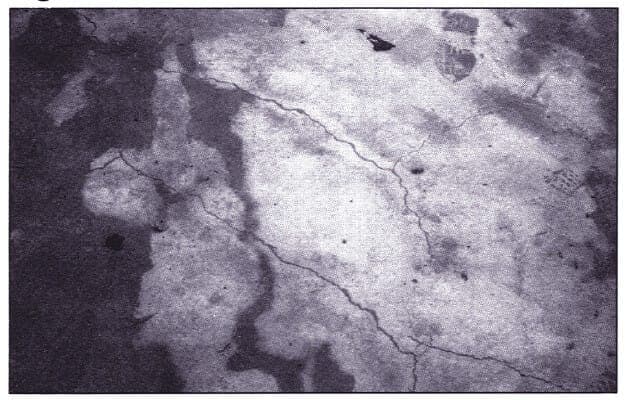

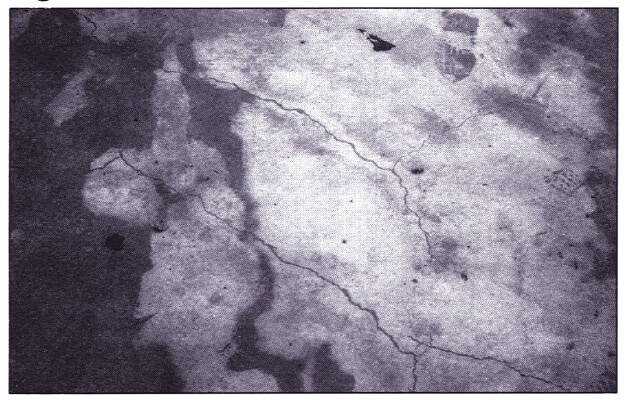

Plastic settlement cracks appear in freshly laid/placed cement concrete in reinforced structure. The plastic settlement cracks also occur on the surface before the concrete has set, when there is the relatively high amount of bleeding. There is also some form of obstruction (i.e. reinforcement bars) to the downward sedimentation of the solids.

Courtesy - Gujarat Ambuja Cements Ltd.

Fresh Concrete, when placed in deep formwork such as that of column or wall, has a tendency to settle or subside. If this settlement is restrained due to an obstruction like steel bars or large aggregates it causes short horizontal cracks. Also, these obstructions break the back of concrete above them forming the voids under their belly. The subsidence due to a reduction in volume is termed as plastic settlement cracks.

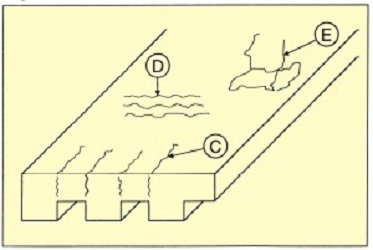

Typical Types of Plastic Settlement Cracks:

Fresh Concrete when laid in the formwork of column, wall or etc., it has a tendency to settle or subside and if this settlement is restrained due to an obstruction like steel bars or large aggregates, it causes plastic settlement cracks.

If the settlement of the solids in concrete can occur freely and without restraint, there will be a reduction in the volume or depth of the actual concrete cast, but no settlement cracking will occur.

Some typical plastic settlement cracks are illustrated in the figures below:

Courtesy - Gujarat Ambuja Cements Ltd.

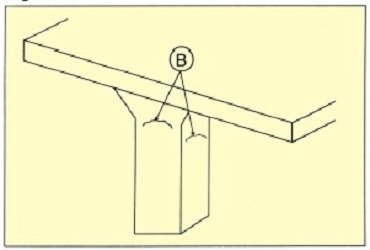

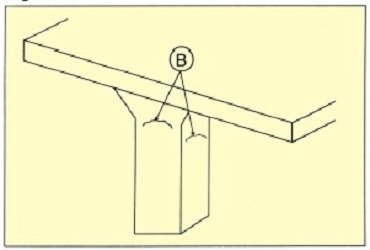

Reinforcement near the top of a concrete section can cause plastic settlement cracking. If the formwork is relatively narrow, concrete may arch or wedge itself across the top of the narrow space and develops cracks

Courtesy - Gujarat Ambuja Cements Ltd.

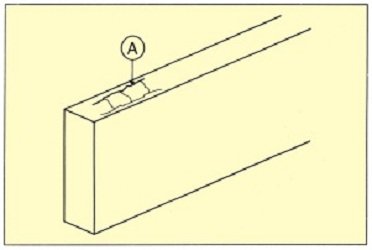

Plastic settlement cracking are those caused by pronounced changes of section such as the cracking below flared column head.

Courtesy - Gujarat Ambuja Cements Ltd.

The changes in section of trough and waffle floor slabs, causes more settlement in the webs than in the comparatively thin flanges and result in cracking.

Courtesy - Gujarat Ambuja Cements Ltd.

If the sub-base or other material against which concrete is being placed is very absorbent like, for example, dry soil or absorbent formwork, an exaggerated type of plastic settlement cracking is likely to occur. In such cases the cracks will usually follow the reinforcement pattern and run parallel to each other.Also Read:

Major Causes of Plastic Settlement Cracks:

- Reduction in the volume of the cement-water system due to bleeding and segregation

- Internal restrainment due to reinforcement steel or large size aggregate

- External restrainment due to relatively narrow formwork

- Pronounced change of concrete cross section

- Absorbent sub base or formwork surface

- Flared column heads, troughs and waffles in floor slabs

- Bulging or settlement of formwork and supporting system

The above factors can singly or collectively cause cracking of concrete

Summary of Plastic Settlement Cracks in Concrete:

| 01. Time of Appearance | – 10 to 180 minutes |

| 02. Types/Locations | – Over formwork tie bolts, or over reinforcement near the top of the section. – In narrow column and walls due to obstruction to sedimentation by resulting arching action of concrete due to a narrow passage. – At the change of depth of the section. – Arching on top of columns |

| 03. Primary Causes | – Non-cohesive concrete mix – Excess bleeding – Over vibration |

| 04. Secondary Causes | – Rapid Early Drying Conditions (a) High ambient temperatures/Hot Sun (b) Low Humidity (c) High Wind velocity |

| 05. Prevent Measures | – Increase finer fines in the fine aggregates and cohesiveness of concrete mix – Avoid using gap graded materials – Use air entrainment – Do re-vibration for proper compaction |

01. Time of Appearance

- 10 to 180 minutes

02. Types/Locations

- Over formwork tie bolts, or over reinforcement near the top of the section.

- In narrow column and walls due to obstruction to sedimentation by resulting arching action of concrete due to a narrow passage.

- At the change of depth of the section.

- Arching on top of columns

03. Primary Causes

- Non-cohesive concrete mix

- Excess bleeding

- Over vibration

04. Secondary Causes

- Rapid Early Drying Conditions

(a) High ambient temperatures/Hot Sun

(b) Low Humidity

(c) High Wind velocity

05. Prevent Measures

- Increase finer fines in the fine aggregates and cohesiveness of concrete mix

- Avoid using gap graded materials

- Use air entrainment

- Do re-vibration for proper compaction