In this modern world, many factors have been influencing a finished product’s look. Many different uses and functions require different types of finishing materials. One of the most widely used finishing materials is veneer. It is an environment-friendly and natural product which is mostly used in the residential and commercial building. It also enhances the look of the door, furniture or any other surface. According to “John Wiley & Sons” (Author of Webster’s New World College Dictionary), ‘Veneer is a very thin layer of a fine wood especially used to cover the wood with the finer quality of sheet which gives a superficially attractive appearance.’

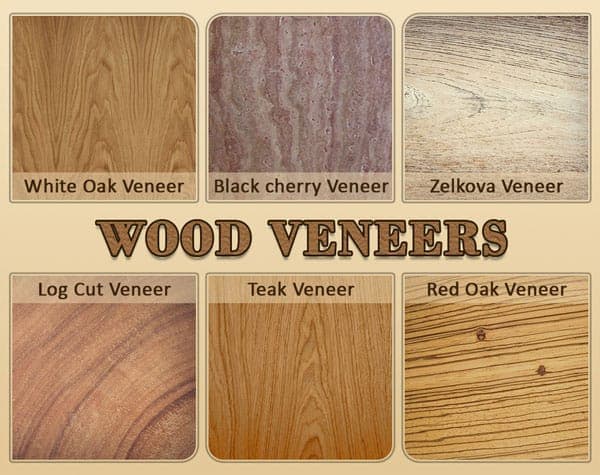

The veneer is a very thin treated slice of wood which is obtained from trees and are categorized as sliced or rotary – cut veneers. According to “W.B.Mckay” (Author of the Building Construction Metric),’ veneer can be cut by two methods i.e. rotary cutting method and veneer slicing machines. Approximately 90% or above of veneers are cut by the simple rotary cutting method.’ After being cut they become wood slices which impart a warm, natural look to the surfaces when they are put in use. Majorly used for furniture and paneling, they are considered as a best option for residential use. In today’s market it offers a range of veneers which are used for wall paneling too.

The thickness of veneers is an important factor in determining its durability. It is said that the more thickness it’ll have, the more durable it’ll be. Additionally, during any repair, it is the thickness which ensures whether the damage could be fixed or not. Different shades, colour and textures (that can be smoked and fumed) are available in the market today. This is the most economical way to use the timber and can easily be recycled when used later. They have an oil-based finishes and water-based finishes as well. They work well with lacquer finishes too. Being a natural product, they have their own class which last longer than laminates and can also be polished according to the client’s desire. Hence, veneer proves to be the best and outclass in furniture and other works where solid wood cannot be used due to its contraction and expansion which is caused by fluctuation of temperature and humidity in the environment.

Also Read:

Different Types of Wood Veneer & Their Uses

Manufacturing Process of Wood Veneer

Different Methods of Veneer Cutting

Veneer has a very sharp and a warm finish that add a unique character with their natural grain and help in attaining a better look and a feel of natural wood. They are crucially and critically used where the touch and feel are vital to the user. It helps in achieving a sharp edge and finishing surfaces with uniformity. It is mostly fitted in offices, conference rooms, reception desks and home offices.

Why Veneer?

- Veneer furniture is affordable and easily available in markets. It is manufactured and assembled instead of being harvested like solid wood.

- Veneer can be designed to provide its appearance with a wide varieties of wood finishes. You may often find pieces that have been made to look like a more non-native species of wood that might not be available in many solid wood collections. Veneer can provide a more uniform and steady finish. It is very much easier to match while adding pieces to a previously decorated room.

- Veneer sheets are always coloured and polished in order to achieve the intended type, colour and grain that matches with the design theme.

- It lasts longer than the solid wood due to its strength and durability. Although, its whole appeal of application is mostly dependent on workmanship on how steadily it has been used and attached, but because of its durability it largely stays intact for a minimum of 15 years if it is maintained properly.

- It is environmental and eco-friendly as it is a renewable resource. One log of timber produces a number of veneer slices, boosting its cost effectiveness and efficiency. In addition, it can be backed by a wood board or plywood board to achieve the desired strength within the overall budget.

What Makes Each Veneer Look Unique?

Every tree is different from others and as far as veneer is concerned it has unique appearance of itself. That same tree can never be found more than once in nature which tells us that the tincture, shade and pattern can fluctuate even within the same species of wood.

The colour and shade of wood veneer is affected and influenced by light in the room which gives veneer a warm feel. The diverse and various copy of different types of wood have made it very difficult for the consumers to distinguish and differentiate between the real natural product and their copies.

The structure of wood veneer is very unique and simple making it different from others. The color which enhance the appearance of the wood, the ability to repair and renovate are some of its advantages which differentiate the real from the copied products. Wood is a uniquely living material. The structural differences, tincture, texture and growth patterns such as notches features the natural product and differentiates from other woods.

Applications of Wood Veneer

Wood veneer is majorly used for interiors in many different ways. It has its ideal use in residential projects, buildings, hotels, offices and many other constructional sites. In addition, veneer is processed to create a variety of different products like panels for cabinets, veneer parquet, flexible veneer sheets, wood veneer boards, veneer wallpapers, etc. It is available in different and diverse varieties. Wood veneers are among the most commonly used decorative materials for surface carpentry, furniture, walls, ceilings, and many more.

Also Read:

Advantages and Disadvantages of Wood Veneers

How To Apply Wood Veneer Sheets: Follow These Simple Steps!

Other Uses of Veneer

- Doors

- Cabinet interiors and exteriors

- Desk and Table tops

- Kitchen tops

- Furniture

- Shelves

- Wall Paneling

Types of Veneer Substrate

There are three main types of veneer substrate depending on the application. The wood is cut from the log, and then applied to the top of the one of the following options:

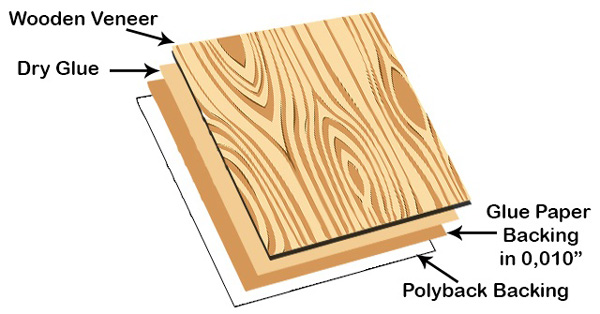

01. Paper- Backed Veneer

It is a kind of veneer that is joined by a paper backing it up. This type of veneer is most commonly used when trying to attach and match curves, in order to make sure that the veneer doesn’t crack or any other form of damage is done to it. This type of veneer is found inside automatic dashboards and interior columns.

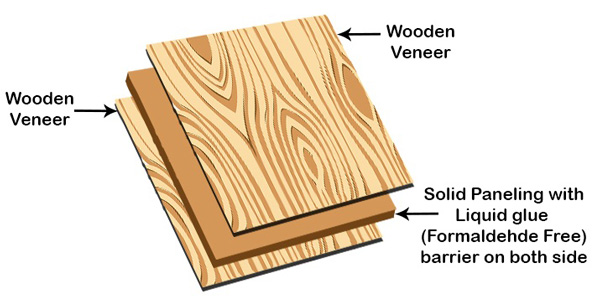

02. Wood-on-Wood Veneer

It is the type of veneer that is to be glued on top of another piece of veneer in order to keep it intact. The veneer which is used on the backside is of lower quality as it cannot be seen. This type is commonly used for decorative interior furnishings of an office or apartment. The grain on the wood that is at the back side is run in the opposite direction to that of the decorative side, to make sure the strength is at its greatest.

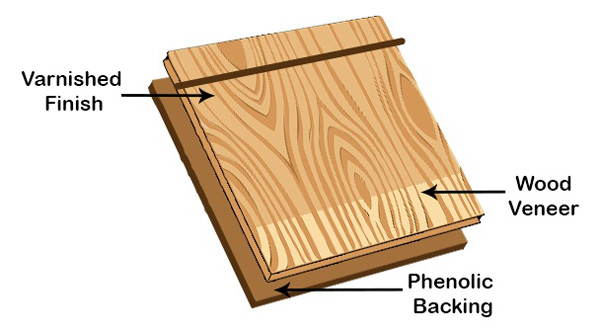

03. Phenolic- Backed Veneer

The phenolic-backed veneer is backed by a plastic and has a very soothing and decorative veneer on the front. An advantage for this type is that the back of veneer is water resistant as it is made up of plastic. It also bends, likewise to paper-backed veneer but not fully same. The best thing of this veneer is that it can be easily cut by a knife whereas for other veneer substrate, a table saw or a hand router is needed. This type of veneer is mainly used in any interior decorative application.

To summarize, veneer is the fully surface finished product. It is a natural and environment friendly product, which is used mostly in residential and commercial spaces. It enhances the look of furniture or surface which makes it easy to sell. It acts as the best element in furniture where the use of wood is avoided. It is majorly used in residences for furniture and panels for cabinet. It is one such material which helps to achieve the desired look within the budget…!

Also Read:

Different Types of Veneer Matching

Wood Veneer: All You Would Like to Know!

Veneer vs Laminate: Make the Right Choice