Workability of concrete is the ease and homogeneity of work with freshly mixed concrete or mortar. In other words, if concreting process such as mixing, placing, compacting and finishing can be done easily in freshly mixed concrete; this is called workability of the concrete.

Simply speaking, workability of concrete is all about how easily freshly mixed concrete can be mixed, placed, consolidated and finished with minimal loss of homogeneity. Or technically speaking, workability of concrete is the amount of useful internal work necessary to produce 100% compaction.

Sometimes, the word ‘consistency’ is also used to describe workability of freshly mixed concrete. Workability measures a fluidity or mobility of concrete. It is said that wet concrete is more workable than the dry concrete. The desired workability of concrete for a particular construction practice varies according to the work condition, weather condition, type of work, mode of compaction etc.

There are primarily three major factors affecting the workability of concrete – water/cement ratio, shape and size of aggregate and admixtures. Workability is described as very low, low, medium, high and very high. And, there are various concrete workability tests available to measure it.

According to the ‘M.M. Goyal’ (Author of Construction Handbook), there is no acceptable test that can measure the workability directly as per the definition. The followings tests for workability of concrete gives a measure of workability, which is applicable specifically concerning some particular methods.

They bear no relationship to any of the common methods of placing and compacting concrete. So, the test results are only relative and should not be given any absolute measurement. We need to understand that each test has their importance, and as such there is no unique test to measure the workability of concrete in total. The significant advantage is the simplicity of the procedure with an ability to detect variation in the uniformity of a mix of given nominal proportion.

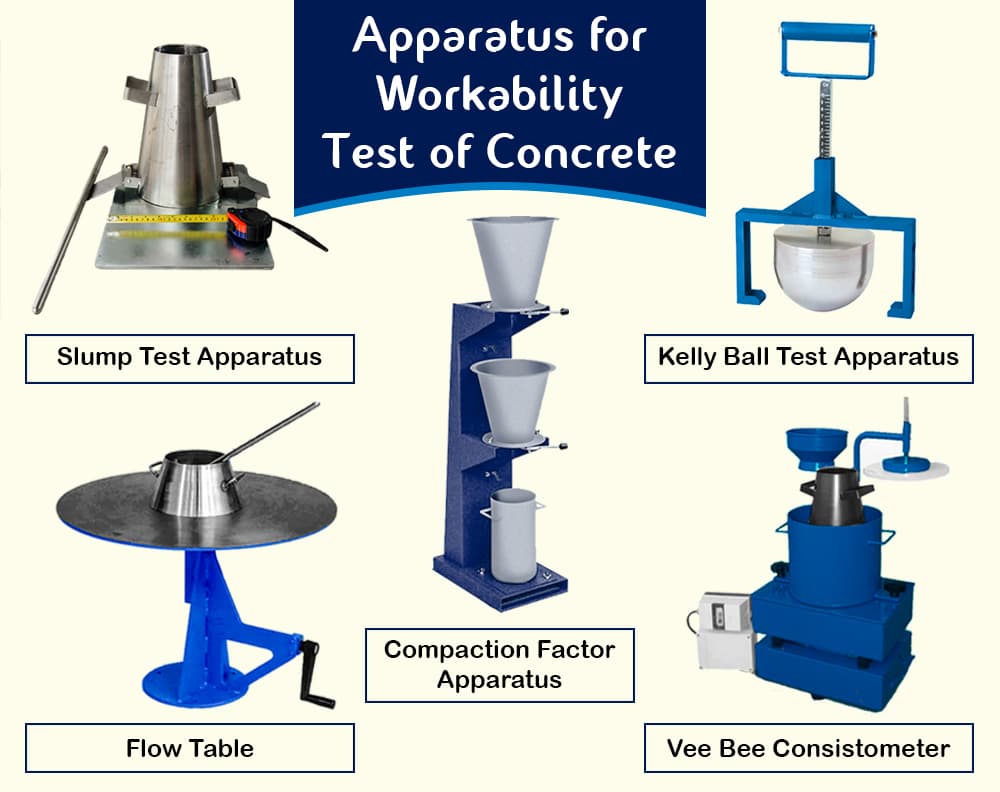

Types of Tests for Workability of Concrete

- Slump Test

- Compacting Factor Test

- Flow Test

- Vee-Bee Consistometer Test

- Kelly Ball Test

01. Slump Test

The concrete slump test or slump cone test is the most common test for workability of freshly mixed concrete which can be performed either at the working site/field or in the laboratory. To maintain the workability and quality of fresh concrete, it is necessary to check batch by batch inspection of the concrete slump. This can be easily done with the concrete slump test. The slump test is the simplest test to determine workability of concrete that involves low cost and provides immediate results.

Recommended Result of Concrete Slump Test

As per IS 456:2000 (Plain and Reinforced Concrete -Code of Practice),

- If the slump of the concrete is in between 0 to 25 mm than it is considered as very low workability of concrete,

- If the slump of the concrete is in between 25 to 50 mm than it is considered as low workability of concrete,

- If the slump of the concrete is in between 50 to 100 mm than it is considered as medium workability of concrete,

- If the slump of the concrete is in between 100 to 150 mm than it is considered as high workability of concrete.

Standard Guidelines for Concrete Slump Test

There are various standard guidelines available to perform the concrete slump test. Such as,

- IS 1199 – 1959,

- ASTM C 143-10,

- BS 1881: 103 :1993 etc.

Slump Test Apparatus

Following apparatus are used for performing the slump test,

- Slump Test Cone (Mould)

- Tamping rod

- Scale for measurement

02. Compaction Factor Test

Compaction factor test works on the principle of determining the degree of compaction achieved by a standard amount of work done by allowing the concrete to fall through a standard height. This is specially designed for laboratory use, but if the circumstances favours, it can also be used on the working site/field.

Compaction factor test of concrete is more precise and sensitive than the concrete slump test; hence it is more favorable and useful for low workable concrete or dry concrete which is generally used when concrete is to be compacted by vibration.

Recommended Result of Compaction Factor Test

According to the ‘A.M. Neville’ (Author of Properties of Concrete), description of the degree of workability and their compacting factor are as follows:

- If the compacting factor is 0.78 than it is considered as very low workability of concrete,

- If the compacting factor is 0.85 than it is considered as low workability of concrete,

- If the compacting factor is 0.92 than it is considered as medium workability of concrete,

- If the compacting factor is 0.95 than it is considered as high workability of concrete.

Standard Guidelines for Compaction Factor Test

There are various standard guidelines available for performing the compaction factor test. Mentioned below are the standard guidelines available,

- IS 1199 – 1959,

- ACI 211.3-75 (Revised 1987),

- BS 1881: 103 :1993 etc.

Compaction Factor Test Apparatus

Following apparatus are used for performing the compaction factor test,

- Compacting factor apparatus – It consist of two conical hoppers and one cylindrical mould

- Tamping rod

- Weighing machine

03. Flow Test

The flow test is a laboratory test, which gives an indication of the quality of concrete with respect to consistency or workability and cohesiveness. In the flow test, a standard mass of concrete is subjected to jolting. This test is generally used for high/ very high workability concrete.

Similar laboratory test named ‘Flow Table Test ‘was developed in Germany in1933 and it has been described in ‘BS 1881:105: 1984’. This method is used for the high and very high workable concrete which would exhibit the collapse slump.

Recommended Result of Flow Test

According to ‘M.S. Shetty’ (Concrete Technology Theory and Practice), the value of flow test may range anything from 0 to 150 %.

Standard Guidelines for Flow Test

There are various standard guidelines available to perform the flow table test. Mentioned below are the standard guidelines,

- IS 1199 – 1959

- ASTM C 124 – 39 (Reapproved 1966)

Flow Test Apparatus

Following apparatus are used for performing the flow table test,

- Flow table

- Mould

- Scale

04. Vee Bee Consistometer Test

Vee bee consistometer test is a good laboratory test on fresh concrete to measure the workability in an indirect way by using a Vee-Bee consistometer. Vee bee test is usually performed on dry concrete and it is not suitable for very wet concrete. Vee bee consistometer test determines the mobility and to some extent compatibility of concrete. In the vee bee consistometer test vibrator is used instead of jolting. Vee bee test determines the time required for the transformation of concrete by the vibration.

Recommended Result of Vee Bee Consistometer Test

According to ‘IS 1199:1959’ (Methods of Sampling and Analysis of Concrete),

- If vee bee time is up to 20 to 15-10 seconds than concrete is considered as in a very dry consistency.

- If vee bee time is up to 10 to 7-5 seconds than concrete is considered as in a dry consistency.

- If vee bee time is up to 5 to 4-3 seconds than concrete is considered as in a plastic consistency.

- If vee bee time is up to 3 to 2-1 seconds than concrete is considered as in a semi-fluid consistency.

Standard Guidelines for Vee Bee Consistometer Test

There are various standard guidelines available to perform the vee bee test. Mentioned below are standard guidelines for Vee Bee Consistometer test,

- IS 1199 – 1959

- ACI 211.3-75 (Revised 1987)

- BS EN 12350-3: 2009.

Vee Bee Consistometer Test Apparatus

Vee bee consistometer is used to perform the vee bee test of concrete, which consists of the following components,

- Vibrating table

- A Metal pot

- A steel metal cone or Slump Cone

- A standard iron rod

To know the test procedure and result calculations, read Vee Bee Test.

05. Kelly Ball Test (Ball Penetration Test)

This test is developed by J.W Kelly, hence it’s known as a Kelly ball test. Kelly ball test is a simple and inexpensive field test which measures workability of fresh concrete with the similar to the concrete slump test, but it is more accurate and faster than a slump test.

This test uses a device that consist of metal hemisphere (ball) thereby indicating the consistency of fresh concrete by its level of penetration when the metal hemisphere drops. Thus, in this test, depth is determined through metal hemisphere, which sinks under its own weight into fresh concrete.

Standard Guidelines for Kelly Ball Test

There is a standard guideline available to perform the Kelly ball test. Mentioned below are standard guidelines for Kelly Ball Test,

- ASTM C360-92 – For ball penetration test

Kelly Ball Test Apparatus

Kelly ball test apparatus is used to perform the Kelly ball test, which consists of the following components,

- Metal hemisphere (Ball)

- Graduated Scale

- Handel

- Frame

Read, Kelly Ball Test to Measure Workability of Concrete! In the mentioned link, we have described in detail its test procedure, and calculations of result.

Why Workability Test Fails? And What if The Test Fails?

There are various reasons for the failure of the workability test of concrete. Some of the major reasons are mentioned below:

- Addition of the excess/less amount of water than the actual quantity required for the concrete mix.

- Poor inspection at batching and mixing plant during batching and mixing of concrete.

- Poor grading of aggregates.

- Improper mixing and batching of concrete.

- Poor quality of concrete ingredient like cement, aggregate, sand, water etc.

If the workability test fails than, it is strongly recommended to reject that material or use it for some non-structural work for the same or lower the grade of the concrete.

Suitable Workability Test for Different Degree of Workability

The table below suggests which workability test is appropriate or suitable for mixes of different degree of workability as per the ‘BS 1881:1983’.

Comparative Table of Workability Tests Result

The knowledge of these tests for workability of concrete helps you to control the degree of workability according to the working condition and helps you achieve good quality concrete by following standard construction practices.

Also Read:

8 Factors that Affect the Workability of Fresh Concrete

Nominal Mix and Design Mix of Concrete: Know the Difference

Field vs Laboratory Testing of Cement