Everyone knows that concrete is a primary material in construction. If there is any deficiency in the concrete manufacturing or other concreting processes such as batching, mixing, transportation, placing, compaction etc. then, it directly affects the quality of the construction. So, all the process has to be done with adequate care and for that workability of concrete has to be maintained according to the nature of work. Workability of the concrete is indicated as an ease to work with fresh concrete. Therefore, it’s necessary to measure workability of fresh concrete after the manufacturing or before starting the pouring of concrete. There are various methods of testing which is available to measure the workability of fresh concrete such as slump test, compacting factor test, flow test, Kelly ball test, Vee Bee consistometer test etc. Here, we are discussing compaction factor test (compacting factor test) i.e. test procedure, testing apparatus, recommended criteria, etc.

What is Compaction Factor Test?

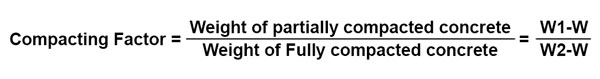

Compaction factor test or compacting factor test determines the degree of compaction which is achieved by a standard amount of work done by allowing the concrete to fall through a standard height. According to ‘Indian Standard, IS 1199-1959’, the compacting factor is the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete.

Why Compacting Factor Test (Compaction Factor Test)?

Compaction factor test determines the workability of concrete and is performed in the laboratory. If circumstances allow then, it can also be done in the field. Compacting factor test is more suitable for the concrete which has low workability or it can be said that for dry concrete. Such kind of concrete is generally used when it’s to be compacted by vibration and which consistently fails to slump, because slump test doesn’t give an accurate result for the low workability concrete, when the slump is less than 50 mm. Hence, in such cases, the compacting factor test of concrete is more precise and sensitive than the concrete slump test.

Standard Guidelines for Compaction Factor Test

Following are the various standard guidelines for performing the compaction factor test of concrete. These are:-

- IS 1199 – 1959

- ACI 211.3-75 (Revised 1987)

- BS 1881-103:1993 etc.

Compacting Factor Test Apparatus

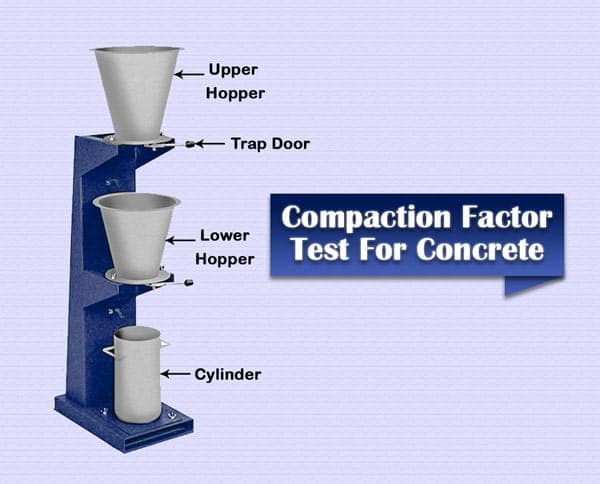

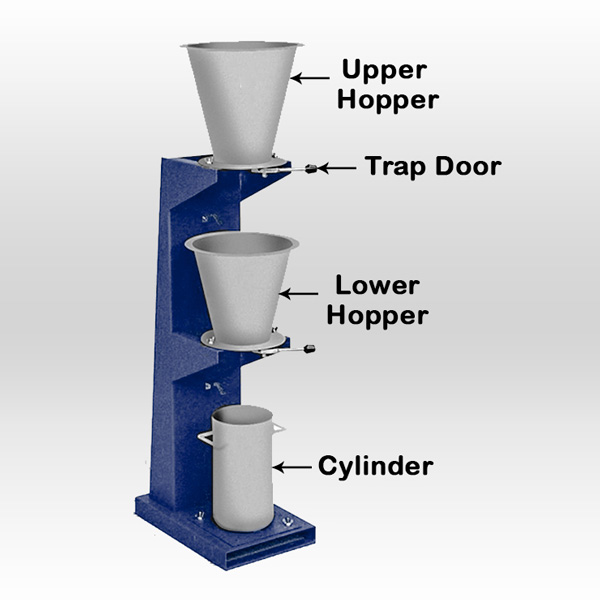

Compacting factor apparatus is used to perform this test, which consists of the following components:-

01. Conical Hoppers (A and B) & Cylinder: Compaction factor test apparatus consists of the two conical hoppers A and B and they are mounted above a cylindrical mould (C). This hopper and cylinder should be rigid and firmly constructed, truly in shape and should be smooth inside. The lower ends of the hoppers should be closed with tightly fitted hinged trap-doors and should consist of quick release catches.

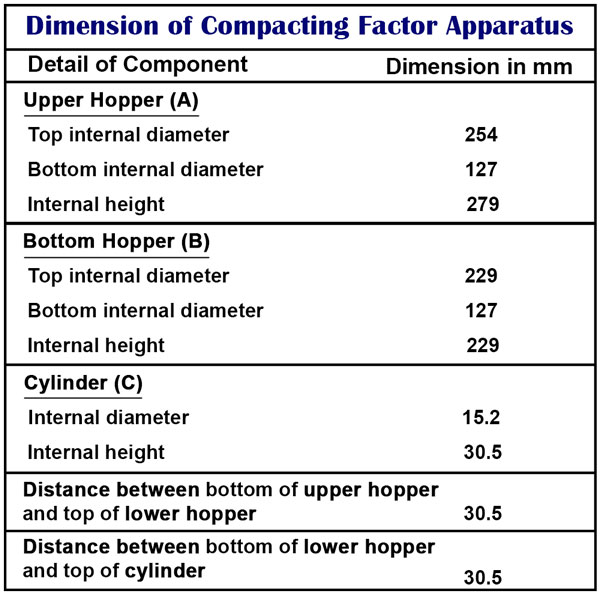

- The dimension of hoppers A & B and cylinder and their distance from each other are mentioned below:-

02. Trowels

03. Hand scoop

04. Steel Rod for compaction

05. Weighing Machine

Compacting Factor Test Procedure

01. Concrete which is to be tested is placed gently in the upper hopper to its edge, using the hand scoop and level the concrete surface.

02. Open the bottom trapdoor of the upper hopper so that concrete will fall into the lower hopper.

03. Before starting this process, the cylinder should be covered; hence concrete can’t enter in the cylinder.

04. Concrete has a tendency to stick, so if concrete sticks in one or both hoppers than concrete can gently be pushed by the steel rod from the top.

05. Immediately after the concrete comes to rest in the lower hopper, the cylinder should be uncovered.

06. Now, open the trap-door of the lower hopper so that concrete can fall into the cylinder.

07. If the excess concrete remains above the top level of the cylinder then, cut off this concrete by using of trowels and level it. After that, wipe and clean the outside surface of the cylinder.

08. Take the weight of the cylinder with concrete (W1). This weight is called as the weight of partially compacted concrete (W1).

09. Now, empty the cylinder and refill it with the same concrete. This time concrete is placed in approximately 5 cm thick layers and rammed. Each layer is rammed heavily to obtain full compaction.

10. Level the top surface of the fully compacted concrete at the top of the cylinder.

11. Again, Wipe and clean the outside of the cylinder.

12. Take the weight of the cylinder with concrete (W2). This weight is called the weight of fully compacted concrete(W2)

13. Now, take the weight of the empty cylinder(W), before taking weight cylinder has to be properly cleaned.

Points to be Taken Care of

01. This test should be carried out at a constant time interval after the completion of mixing of concrete. Convenient time for releasing the concrete from the upper hopper is two minutes after the completion of mixing.

02. Compacting factor test of concrete is used only for the concrete where nominal maximum size of the aggregate does not exceed 38 mm.

03. At the first fall of the concrete (upper hopper to lower hopper), the cylinder must be covered, so that concrete can’t enter in the cylinder.

04. Compaction factor test should be carried out in a place free from vibration or shock.

Result Calculation

Recommended Result of Compacting Factor Test

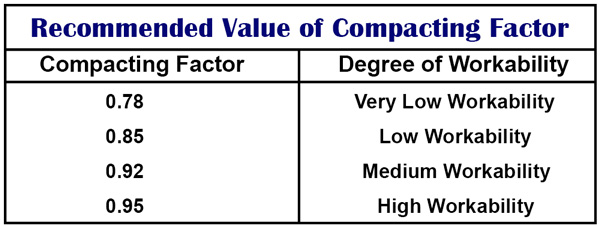

According to ‘A.M. Neville’ (Honorary member of American concrete Institute, Author of Properties of Concrete), the values of compacting factor for different workability is mentioned below:-

Compacting factor test is more suitable for measuring concrete workability. It’s also appropriate to detect variation in workability over a wide range. This workability test is very easy and simple both to the perform as well as result value analysis. Compaction factor test is a more precise and sensitive test to check low workability concrete over the high workability one.

Also Read:

Vee Bee Test to Determine the Workability of Fresh Concrete!

Flexural Strength Test to Check Tension in Concrete

Cube Test to Check the Compressive Strength of Concrete