A structure is composed of several connecting elements of construction like walls, beams, columns, foundation, slabs etc. Out of these, slab is of utmost importance. It helps the other components of the building to withstand different loads. There are different types of slab in construction. But in this article, we have discussed types of concrete slab in detail.

What is a Slab in Construction?

Slab is a flat, two-dimensional planar structural component of building having a very small thickness compared to its other two dimensions. It provides a covering shelter or working flat surface in buildings. Its primary function is to transfer the load by bending in one or two directions. Reinforced concrete slabs are used in roofs, floors, ceilings and as the decks of bridges. The floor system of a structure can takes many forms such as in situ solid slab, pre-cast units, ribbed slab etc. Slabs may be mounted on either steel or monolithic concrete beams, walls or even directly over the columns. Concrete slab behaves primarily as a flexural member and its design philosophy is similar to that of beams.

Function of Slab

01. To Provide a flat surface

02. To support load

03. To act as Sound, heat and fire insulator

04. The upper slab becomes the ceiling for the storey beneath it

05. Space between slab and ceiling can be used for placing building utilities

Also Read: What are the Structural Components of the Buildings?

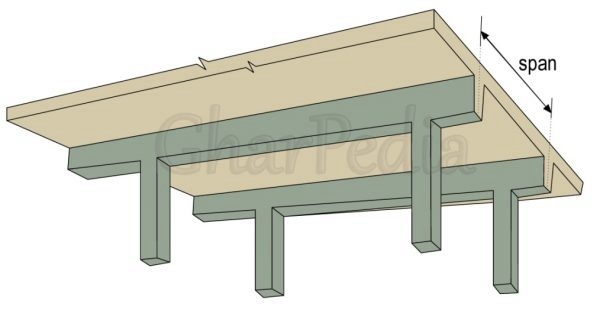

Effective Span of the RCC Slab

Effective span of slab should be lesser of the two

01. L = Clear span + d (effective depth of slab)

02. L = Center to center distance between the support

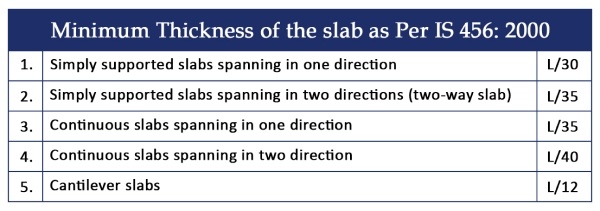

Minimum Thickness of Concrete Slab

Thickness of the slab is decided based on span to depth ratio as given in IS 456: 2000.

Reinforcement in Reinforced Concrete Slab

The diameter of reinforcement bar commonly used in slabs are: 8 mm, 10 mm, 12 mm and 16 mm.

According to ‘IS 456:2000’ (Plain and Reinforced Concrete – Code of Practice), the maximum diameter of bar that can be used in the slab should not be more than 1/8th of total depth of slab i.e. D/8.

In slab, maximum spacing of the main bar should be 3 times effective depth or 300 mm whichever is lesser. For distribution bars, the maximum spacing should be 5 times the effective depth or 450 mm whichever is lesser.

Buy A Building Construction Book

Types of Concrete Slab

01. Conventional Slab

a) One Way Slab

b) Two-Way Slab

02. Flat Slab

03. Hollow Core Ribbed Slab

04. Waffle Slab

05. Sunken Slab

06. Inclined Slab

07. Slab with Arches

08. Prestressed Concrete Slab

a) Pre-Tensioned Slab

b) Post-Tensioned Slab

09. Cable Suspended Slab

10. Composite Slab

11. Precast Slab

12. Slab on Grade or Slab on Ground

a) Stiffened Raft Slab

b) Waffle Raft Slab

13. Bubble Deck Slab

14. Hardy Slab

15. Waist Slab

Let’s understand different types concrete slab in brief.

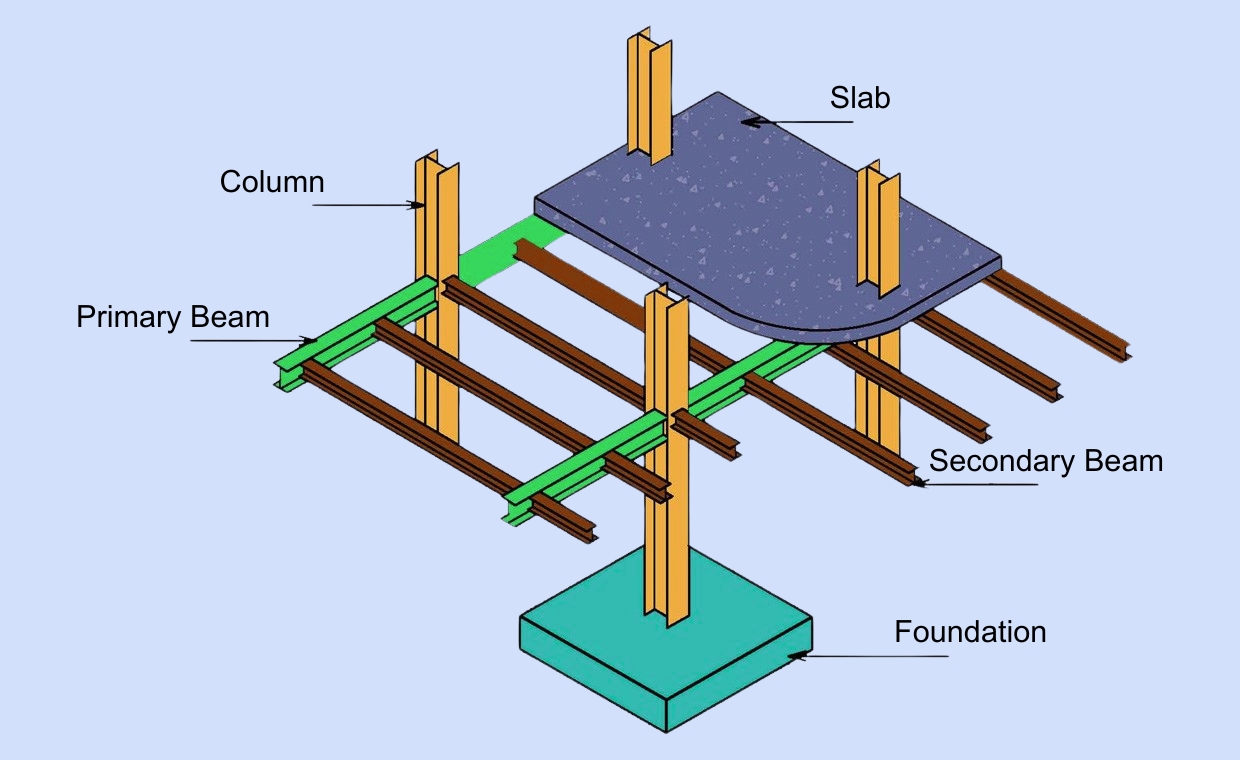

01. Conventional Slab

Generally, it is supported either on walls or on beams and columns. Here, the thickness of slab is small whereas depth of beam is large. In conventional slab, load is transferred to either walls or beams and then from beams to columns. It requires more formwork as compared to the flat slab. But there is no need of providing column caps as in flat slab.

Conventional slab is classified into the following two types based on their geometry i.e. length and breadth:

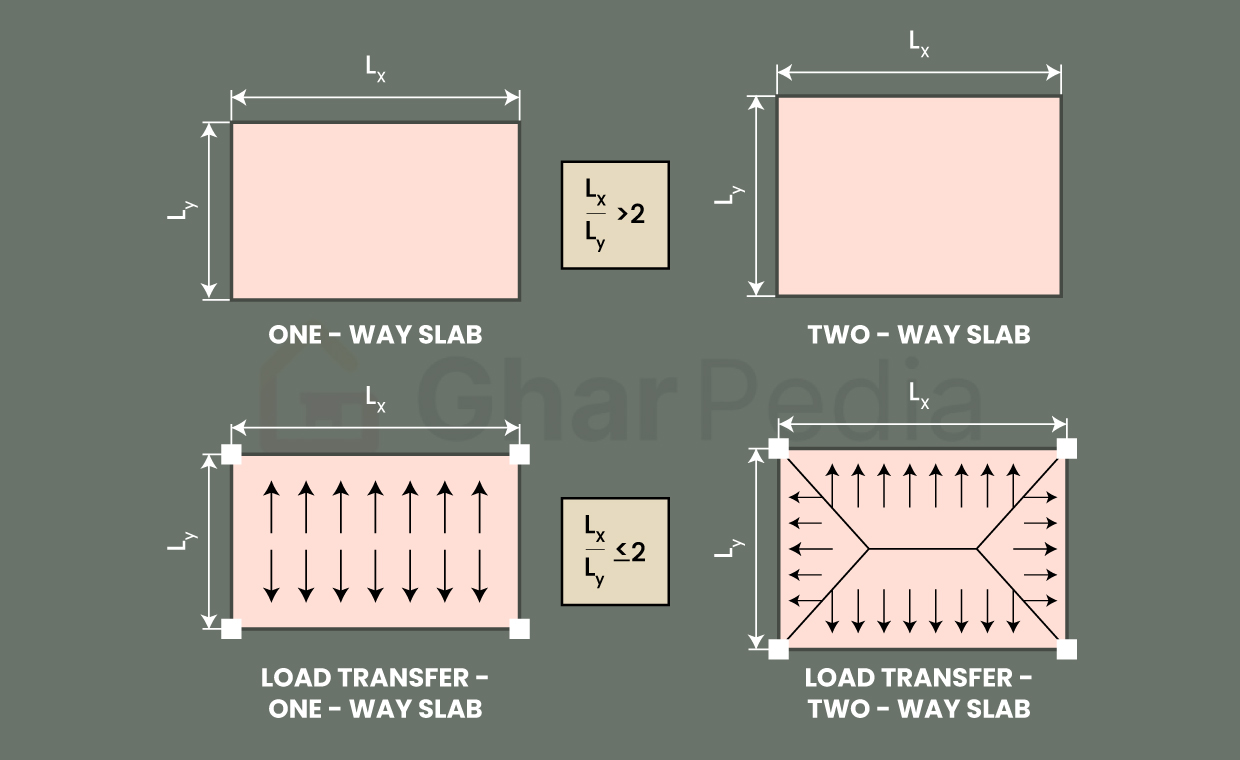

a) One Way Slab:

The slab which is supported on beams on the two opposite sides to carry the load along one direction only is called one-way slab. When the ratio of longer span (l) to shorter span (b) is equal to or greater than two (l/b > 2), it is considered as one-way slab because this slab will bend in one direction only i.e. in the direction along its shorter span.

b) Two Way Slab:

The slab which is supported on beams on all the four sides and the loads are carried by the supports along both directions is called two-way slab. In this slab, the ratio of longer span (l) to shorter span (b) is less than two (l/b<2). These slabs are likely to bend along both the spans. In a two-way slab, load is transferred in both the directions to the four supporting edges and hence reinforcement is provided in both the directions.

According to ‘R. Chudley & R. Greeno’ (Author of Building Construction Handbook), simply supported slab are slabs which rest on a bearing i.e. they are not considered to be fixed to the supports and are therefore free to lift theoretically. In practice, however, they are restrained from unacceptable lifting due to their own self weight and other loads.

02. Flat Slab

It is a reinforced concrete slab supported directly on concrete columns or caps. Flat slab is also called beamless slab because it is supported on columns. Here, the loads are directly transferred to the columns.

The primary function of a flat slab is to provide plain ceiling surface, giving better diffusion of light. They are generally used in parking decks, hotels, commercial buildings or places where beam projections are not desired for height restrictions or even for aesthetics.

03. Hollow Core Ribbed Slab

Hollow core ribbed slabs derive their name from the voids or cores which run through the units. The cores can function as service ducts and undoubtably reduce the self-weight of the slabs, maximizing structural efficiency. The cores also have sustainability advantage as it reduces the volume of material used.

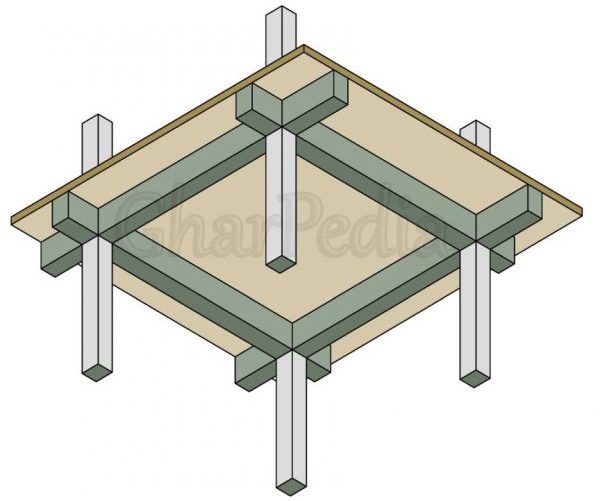

04. Waffle Slab

Waffle slab is a reinforced concrete roof or floor containing square grids with deep sides. It is also called as a grid slab. Waffle slab is majorly used at the entrance of hotels, Malls and Restaurants for good pictorial view and to install artificial lighting. Its primary function is to carry heavier loads and span longer distances than flat slabs as these systems are light in weight and can be used as both ceiling and floor slab. They are also used where there is a restriction on depth of beams for getting clear height.

Waffle slabs are classified based on the shape of Pods (PVC Trays) into:

- Triangular pod system

- Square pod system

05. Sunken Slab

Slab which is provided below the washrooms to hide the sewage pipes or WC pipes or other fixtures is known as sunken slab. Since the pipes from which water passes are concealed below the floor, care has to be taken to avoid leakage problems. Proper waterproofing as well as treatment must be provided in sunken slab to prevent leakage or dampness. After casting sewage pipes in the slab, the slab is filled with broken pieces of bricks or coal or suitable lightweight materials.

Also Read: Need of Waterproofing for Your House!

06. Inclined Slab

This is an inclined concrete slab. It is mostly used in small houses having sloping roofs/pitched roof for aesthetics and for flow of snow or rainwater.

07. Slab with Arches

This type of slab is generally adopted in the construction of bridges. Bridges are subjected to horizontal load due to flood water, wind load and moving load from the vehicles. Slab with arches are adopted at a place where there is a need of redirecting wind load and if there is a long curve in direction of slab. It resists heavy wind load.

They were originally built of bricks or stones but nowadays they are built of steel and reinforced concrete.

08. Prestressed Concrete Slab

a) Pre-Tensioned Slab:

The slab in which steel is tensioned before placing the concrete is called pre-tensioned slab. The slab has same features of post tensioning.

b) Post-Tensioned Slab:The slab in which cables or steel tendons are tensioned after concreting is called post tensioned slab. Reinforcement is provided to resist the compression. In this slab, the reinforcement is replaced with cables/ steel tendons.

Post-tensioning overcomes the natural weakness of concrete in tension and also makes better use of its strength in compression.

09. Cable Suspended Slab

If the slab has very long span, then we go for cable suspended slab which is supported on cable such as Howrah bridge, London bridge etc. Usually, in the construction of houses, we provide a column at every 3 to 5 m, whereas in cable suspension we provide a column almost at 500 m. This type of slab is provided where the length of the span is more and there is difficulty in building columns. The slabs are tied with cables and these cables are connected to columns.

10. Composite Slab

Generally, it is constructed in reinforced concrete cast on top of profiled steel decking. The decking acts as working area and formwork during the construction phase, and it also acts as external reinforcement during life of the slab.

11. Precast Slab

Precast concrete slabs are casted and cured in manufacturing plants, and then delivered at site for erection. The biggest advantage of precast concrete slab is that, as they are manufactured in plants, their efficiency is increased and higher quality control is achieved over the on-site concrete slabs.

Additionally, it is observed that precast concrete slabs are cheaper than cast in situ concrete slab by approximately 24%. Though you spend more for erection, you save a lot in formwork.

Type of most commonly used precast slabs are the channel and double-T types.

12. Slab on Grade or Slab on Ground

The slab which is casted on the surface of the earth is known as Ground slab. It is used in the Basement floor or at plinth level.

It is suitable for a well-compacted stable ground rock or confined sand which is not influenced by moisture, and soils that does not undergo even slight movement due to moisture.

According to ‘Francis D. K. Ching’ (Author of Building Construction Illustrated), concrete slabs on grade require the support of a levelled, stable, uniformly dense or properly compacted soil base containing no organic matter. When placed over soil of low bearing capacity or over highly compressible or expansive soils or filled by soil, a concrete ground slab must be designed as a mat or raft foundation, which requires professional design and analysis by a qualified structural engineer.

There are two types of slab on grades:

a) Stiffened Raft Slab:

It is same as slab on ground. But, it has stiffening beams which are set in channels through the middle of the slab. It, therefore, forms a kind of supporting grid of concrete on the base of the slab. According to ‘Cement Concrete & Aggregates Australia,’ a stiffened raft consists of a concrete slab on ground stiffened by integral edge beams and a grid of internal beams. Internal beams are not required on stable sites while for more-reactive sites the beam sizes and quantity of steel reinforcement are increased to suit foundation conditions. Stiffened raft slab generally requires only one concrete pour. On uncontrolled and filled sites, they can be adopted with supports or mass concrete piles/piers found in natural material, or concrete.

If stiffened raft slab is provided with deep edge beams, then the latter would retain the controlled or rolled fill under the slab.

b) Waffle Raft Slab:

It is constructed fully above the ground by pouring concrete over a grid of polystyrene blocks known as ‘void forms’. Waffle raft slabs are normally suitable for sites with less reactive soil, and are generally easier to install and cheaper than other types. These types of slabs are favorable only for very flat ground.

13. Bubble Deck Slab

According to ‘Immanuel Joseph Chacko’ (2016) (Published in: Study on Structural Behaviour of Bubble Deck Slab using Indian Standards), bubble deck slab is a kind of slab in which voids are created in it in order to reduce the dead weight of building by placing of balls in the slab. Bubble deck eliminates up to 35% of the structural concrete.

It is constructed by using plastic bubbles which are prefabricated and the reinforcement is then placed between/over plastic bubbles and finally, fresh concrete is poured. The plastic bubbles replace the unwanted concrete at the center of the slab.

Bubble Deck slabs increase strength, reduce weight, and hence larger spans can be provided. Fewer columns are needed, and no beams or ribs are required under the ceiling.

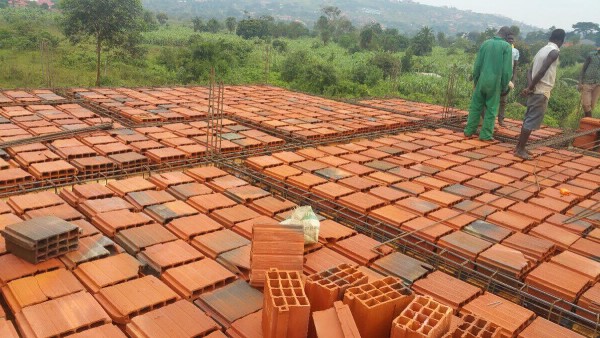

14. Hardy Slab

This type of slab is constructed by hardy Bricks. Hardy bricks are the hollow bricks and made up of concrete. These bricks are used to fill portions of the slab thickness which saves the amount of concrete and therefore the self-weight of the slab is reduced. These kinds of slabs are generally seen in Dubai and China. Hardy slab is used in areas where temperatures are very high. The thickness of slab is increased to resist the temperature from top of the slab. The heat which is coming from walls are resisted by using special bricks which has thermocol in it.

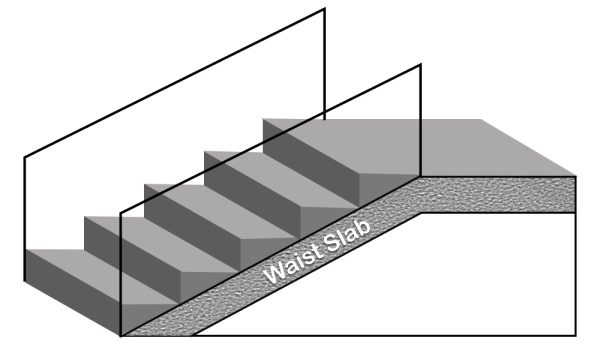

15. Waist Slab

It is a slab on which steps of the staircase rests. According to ‘IS 456’ (Plain and Reinforced Concrete Code of Practice), the depth ‘d’ (thickness) of the waist slab is defined as the minimum thickness perpendicular to the soffit of the staircase.

To sum up, in structural system, slab forms the floor system which apart from providing a flat working surface, resist gravity loads (dead loads and live loads) acting on it and transmits these loads to the vertical framing system like walls and columns. Slabs are frequently used as floor and roof in buildings, decks in bridges, top and bottom of tanks, slab on grade (grade slab), staircases, etc. It requires due consideration during its design and execution. Slabs support all basic load throughout their life as all human activities and facilities are performed on them. Different types of slab are provided at different places based on type of structure, uses, budget, and time, and local skills available.

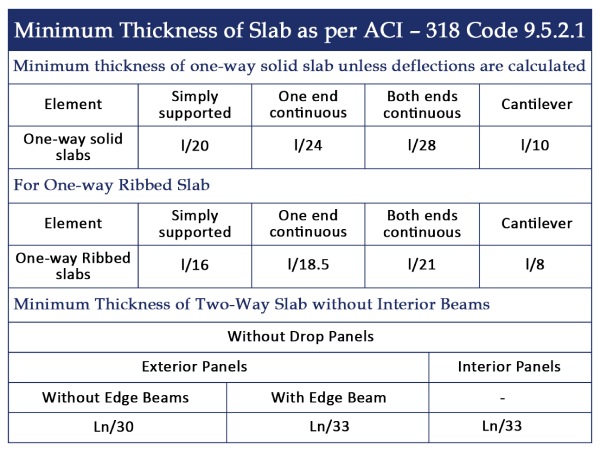

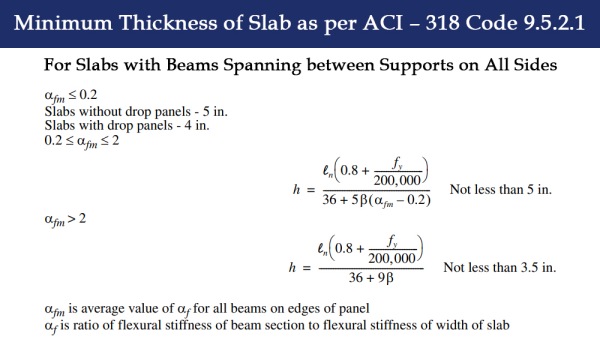

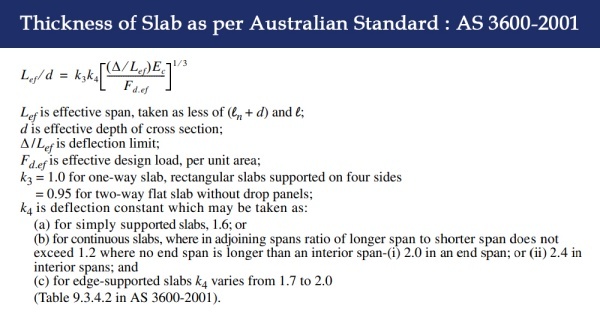

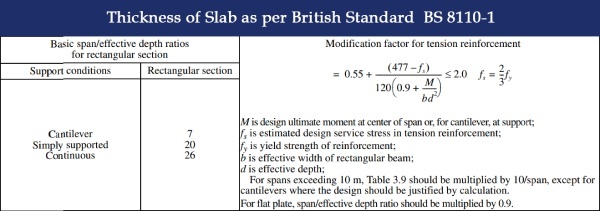

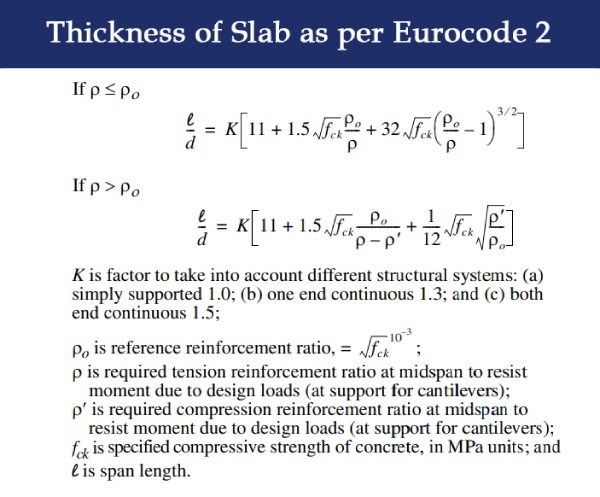

Here we have given minimum thickness provisions for slabs as per different countries code.

Minimum Thickness of Reinforced Concrete Slab as per ACI (American Concrete Institute)

To control deflection, ACI-318 Code 9.5.2.1 specifies minimum thickness values for one-way solid slabs, shown in table. These values are applicable for normal loading conditions and for slabs not supporting or attached to partitions or other construction likely to be damaged by large deflections.

For Slabs with Beams Spanning between Supports on all Sides

Thickness of Slab as per Australian Standard

Thickness of Slab as per British Standard

Thickness of Slab as per Eurocode

Must Read:

Difference Between Lintel & Beam in Structural System!

Difference Between Concrete Beam & Column

Differentiate between Braced and Unbraced Columns

Expertise Concrete Contractors

Image Courtesy: Image 7, Image 8 – sellers2002.files, Image 9, Image 11, Image 13, Image 14, Image 15 – findorff, Image 16, Image 18, Image 19, Image 20, Image 21, Image 22